Wiskind——The role of high efficiency filters in clean rooms

Clean room enclosure system is composed of clean room wall panel system, ceiling system, door, window and clean room equipment.Today's clean room has been widely used in electronics, aerospace, machinery, chemical, pharmaceutical, food, medical, biological engineering......All walks of life.Moreover, with the rapid development of national economy and scientific research, the application of air shower and clean room will be more and more extensive and important.

High efficiency air filter HEPA (high efficiency particulate airfilter), under the rated air flow, the particle size is greater than or equal to 0.3 microns particle capture efficiency is above 99.9% and the airflow resistance in the air filter under 250 pa.

Ultra low penetration airfilter (ULPA), an airfilter used to penetrate particles of particle size 0.1-0.2m with a penetration efficiency above 99.999% and air resistance below 280Pa at rated air volume.

In order to ensure the filtration efficiency of the filter and the cleaning effect of the cleaning system, the high efficiency filter installation must comply with the requirements of clean room construction and acceptance code or design drawing.

1. Preparation before installation in order to prevent hepa from being polluted, the air cleaning system must be installed after the unpacking inspection and installation. The air conditioner, hepa box, air duct and clean room must be cleaned.Before installation, check the flatness of the end face of the filter frame or edge mouth, and the allowable deviation of the flatness of the end face should be no more than 1mm each.

If the flatness of the end surface exceeds the allowable deviation, only the frame end surface of the filter installation is allowed to be modified or adjusted, and the outer frame of the filter itself is not allowed to be modified, otherwise the filter material or sealing part in the filter will be damaged, reducing the filtering effect.

2. Installation requirements when installing hepa filters, ensure that the direction of airflow is consistent with the arrow mark on the outer frame.High efficiency filters assembled with corrugated plates must be vertically mounted, not in reverse.The high efficiency filter and the frame of the assembly high efficiency filter are usually sealed by the jacking method and the pressing method.

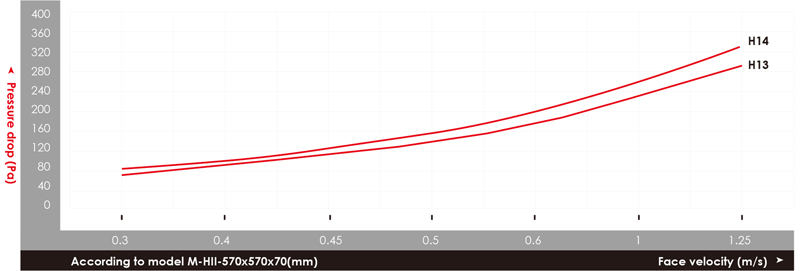

Graph of Initial Pressure Drop versus Face Velocity

Air Inlet Collar and Damper Dimension

|

Air Inlet Collar Diameter (mm)

|

Air Inet Collar Standard Height (mm)

|

Damper Standard Height (mm)

|

|

¢ 250

|

60

|

230

|

|

¢ 300

|

60

|

280

|

|

¢ 350

|

60

|

330

|

|

¢ 400

|

60

|

430

|

Product Specifications

|

Filter Dimension

|

Casing Dimension

(Top Air Inlet)

|

Casing Dimension

(Side Air Inlet)

|

Air Flow

at 0.75m/s

|

Air Inlet

Collar Diameter

|

Rectangular Inlet

Collar Dimension

|

Filter Initial

Pressure Drop

|

|

L×W×H(mm)

|

L×W×H(mm)

|

L×W×H(mm)

|

(m3/h)

|

(mm)

|

(mm)

|

PAO H13(Pa)

|

PAO H14(Pa)

|

|

430×430×80

|

500×500×280

|

500×500×450

|

500

|

250

|

200x200

|

180

|

205

|

|

430×430×100

|

500×500×300

|

500×500×450

|

500

|

250

|

200x200

|

150

|

170

|

|

610×610×80

|

680×680×280

|

680×680×450

|

1000

|

300

|

300x200

|

180

|

205

|

|

610×610×100

|

680×680×300

|

680×680×450

|

1000

|

300

|

300x200

|

150

|

170

|

|

915×610×80

|

985×680×280

|

985×680×450

|

1500

|

350

|

400x200

|

180

|

205

|

|

915×610×100

|

985×680×300

|

985×680×450

|

1500

|

350

|

400x200

|

150

|

170

|

|

1220×610×80

|

1290×680×280

|

1290×680×450

|

2000

|

350

|

500x200

|

180

|

205

|

|

1220×610×100

|

1290×680×300

|

1290×680×450

|

2000

|

350

|

500x200

|

150

|

170

|

|

1220×915×80

|

1290×985×280

|

1290×985×450

|

3000

|

Φ300*2 / Φ450*1

|

630x200

|

180

|

205

|

|

1220×915×100

|

1290×985×300

|

1290×985×450

|

3000

|

Φ300*2 / Φ450*1

|

630x200

|

150

|

170

|

Remarks:

1. Side air outlet model only available with square port.

2. Dimensions above is suitable for mechanical-sealed and design with PAO testing port.

3. Tolerance of performance initial pressure drop is ± 10%.

Each type air filter in use after a period of time, due to capture the various filters filter material surface dust, so that the filtering efficiency of air filter and air filter resistance to drop, affects the central air conditioning unit or clean engineering supporting efficient delivery of air supply outlet, cleanliness and efficiency, the need to replace the air filter in time, to ensure that the air cleanliness requirements.

All kinds of air filters and hepa filters are not allowed to tear or open the packaging bags or film by hand before installation.Air filters should be stored in strict accordance with the direction standards marked on the hepa packing case.In the process of hepa filter handling, should be handled, put, avoid violent vibration and collision.