1.0-2.0 Ton Walkie Electric Pallet Stacker ESL Series

Electric Walkie Lifting Stacker is a common warehousing and logistics equipment. It replaces traditional manual handling with electric drive and realizes the lifting and lowering of goods through a hydraulic system. Operators can follow and operate the vehicle on foot to achieve short-distance handling and stacking operations of goods. The lifting capacity of Lithium Electric Pallet Jack Stacker is between 1 and 2 tons, and the maximum lifting height can reach about 6 meters, which can meet the needs of most warehousing and handling scenarios. Full Electric Forklift Stacker has a certain climbing ability and can generally drive normally on slopes of 5% - 10%, adapting to different working site conditions. At the same time, the high-performance storage battery equipped with MHE Electric Powered Stacker Truck can meet the continuous operation requirement of 4 to 8 hours for a single charge. For some special environments, such as explosion-proof environments and low-temperature environments, the walk-behind electric stacker can be specially customized. According to the special needs of customers, the vehicle can be customized with special functions, such as weighing function and automatic guidance function. It can also be customized and refitted in a targeted manner according to the needs of special attachments.

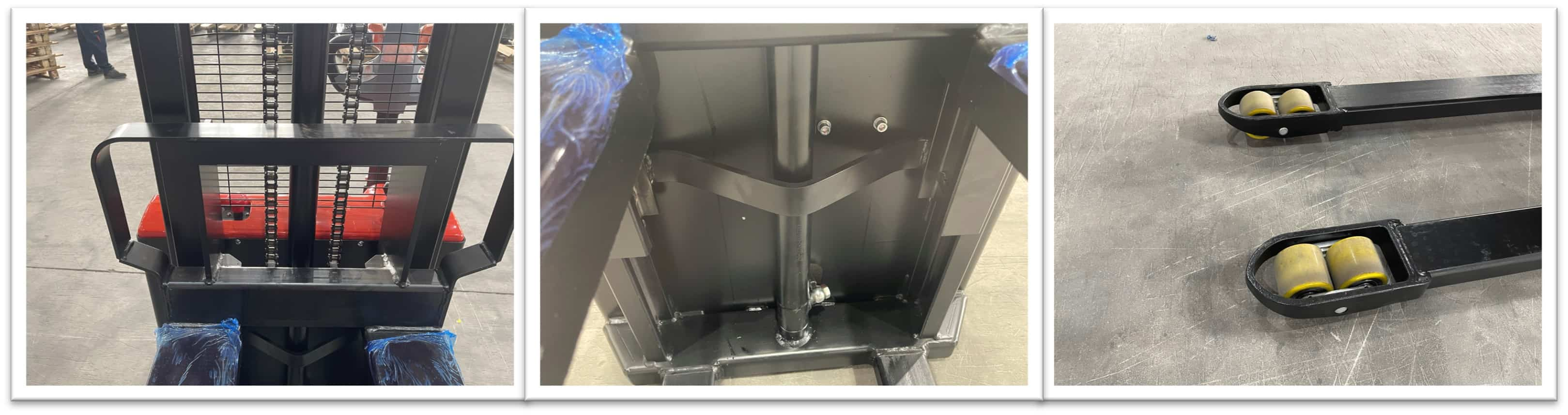

Details & Advantages

Compact and Flexible Body Design

1) Small and Lightweight: The body is relatively small, and the overall dimensions are compact, enabling it to move freely through narrow passages and in limited spaces.

2) Flexible Steering: With an advanced steering system design, the vehicle has an extremely small turning radius. Operators can easily control the vehicle to turn in confined spaces.

Humanized Operation Design

3) Easy-to-Operate Control Handle: The control handle conforms to the principles of ergonomics. It has a simple and clear design, integrating various control buttons, such as forward, backward, lift, lower, accelerate, decelerate, etc.

4) Good Vision Design: Operators can have a broad view during the operation process, clearly seeing the handling and stacking of goods as well as the surrounding working environment.

Efficient Power and Hydraulic System Design

5) Electric Drive System: It adopts a high-performance electric drive system, which has the advantages of strong power, stable operation, and low noise.

6) Advanced Hydraulic System: Equipped with an advanced hydraulic system, it can precisely control the lifting speed and height of goods, achieving smooth and rapid lifting and lowering operations of goods. The hydraulic system also has an overload protection function. When the weight of the goods exceeds the rated load capacity of the vehicle, the system will automatically stop the lifting operation.

Safe and Reliable Design

7) Multiple Safety Protection Devices: A variety of safety protection devices are designed, such as emergency stop buttons, collision avoidance devices, overload protection systems, anti-skid devices, etc.

8) Stable Body Structure: The body is made of high-strength steel, with a sturdy and stable structure, capable of bearing a large weight of goods and external impacts.

FAQ

1) What is terms of payment?

T/T, 30% deposit, 70% balance paid before shipment.

2) What is the inspection method?

Product photos, packaging, videos, and any other inspection methods required by customers.

3) How is the product packaged?

Naked, packaging film, wooden box, iron frame, and other required packaging methods.

4) How long is the warranty period?

18 months. Spare parts are provided free of charge during the warranty period.