Product Item: 1-2000ml ARC- Conical Alumina Ceramic Crucible

Apllication:

Main purpose of alumina crucible and sagger is as a container for analysis and firing of material and product applied in various industries. For example: analysis of coal, melting of the metal, analysis and firing of chemical raw materials, analysis and melting of glass, analysis and firing of rare earth materials and mineral,firing of high temperature items such as ceramic products and melting of single-crystal raw materials.

Usage:

Under normal circumstances,firstly put the items which need to be analyzed and fired into the crucible or sagger.Then heat. The speed of heating and drop in temperature are according to the characteristics of equipment and products, fast or slow.Because of the thermal expansion of raw material which the crucibles and saggers are made of, too quick heating or cooling will easily lead to cracking of the crucibles and saggers.The best way is slowing down,which can prolong the life of them.

Size :

|

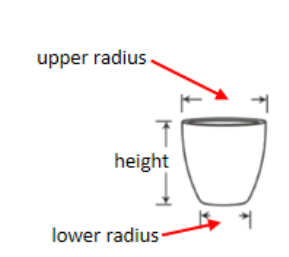

ARC-shape Conical Alumina Crucible

|

|

Item NO.

|

volume (ml)

|

Upper radius (mm)

|

Lower radius (mm)

|

Height (mm)

|

|

Item NO.

|

volume (ml)

|

Upper radius (mm)

|

Lower radius (mm)

|

Height (mm)

|

|

CS-AC-001

|

1

|

15

|

10

|

7

|

|

CS-AC-035

|

90

|

55

|

48

|

53

|

|

CS-AC-002

|

1.5

|

20

|

15

|

9

|

|

CS-AC-036

|

100

|

57

|

37

|

58

|

|

CS-AC-003

|

2.5

|

37

|

35

|

5.5

|

|

CS-AC-037

|

100

|

61

|

36

|

54

|

|

CS-AC-004

|

3

|

17

|

11

|

25

|

|

CS-AC-038

|

100

|

61

|

31

|

60

|

|

CS-AC-005

|

3

|

20

|

16

|

17

|

|

CS-AC-039

|

100

|

62

|

40

|

53

|

|

CS-AC-006

|

4

|

25

|

14

|

20

|

|

CS-AC-040

|

120

|

66

|

30

|

55

|

|

CS-AC-007

|

4

|

22

|

14

|

24

|

|

CS-AC-041

|

120

|

63

|

33

|

73

|

|

CS-AC-008

|

4

|

25

|

19

|

18

|

|

CS-AC-042

|

140

|

55

|

48

|

72

|

|

CS-AC-009

|

5

|

25

|

18

|

22

|

|

CS-AC-043

|

150

|

68

|

42

|

80

|

|

CS-AC-010

|

7

|

28

|

21

|

13

|

|

CS-AC-044

|

150

|

73

|

43

|

67

|

|

CS-AC-011

|

10

|

28

|

20

|

27

|

|

CS-AC-045

|

200

|

70

|

44

|

85

|

|

CS-AC-012

|

10

|

30

|

18

|

30

|

|

CS-AC-046

|

200

|

82

|

43

|

70

|

|

CS-AC-013

|

9

|

38

|

28

|

17

|

|

CS-AC-047

|

200

|

83

|

48

|

86

|

|

CS-AC-014

|

10

|

30

|

20

|

28

|

|

CS-AC-048

|

250

|

75

|

51

|

93

|

|

CS-AC-015

|

15

|

32

|

21

|

35

|

|

CS-AC-049

|

250

|

90

|

53

|

76

|

|

CS-AC-016

|

15

|

35

|

21

|

30

|

|

CS-AC-050

|

300

|

83

|

52

|

106

|

|

CS-AC-017

|

19

|

34

|

20

|

38

|

|

CS-AC-051

|

300

|

88

|

53

|

85

|

|

CS-AC-018

|

20

|

34

|

24

|

39

|

|

CS-AC-052

|

400

|

75

|

56

|

122

|

|

CS-AC-019

|

20

|

35

|

18

|

35

|

|

CS-AC-053

|

400

|

80

|

58

|

108

|

|

CS-AC-020

|

20

|

38

|

20

|

29

|

|

CS-AC-054

|

400

|

86

|

49

|

135

|

|

CS-AC-021

|

20

|

38

|

24

|

35

|

|

CS-AC-055

|

500

|

86

|

50

|

140

|

|

CS-AC-022

|

25

|

36

|

22

|

42

|

|

CS-AC-056

|

500

|

100

|

60

|

118

|

|

CS-AC-023

|

25

|

39

|

24

|

38

|

|

CS-AC-057

|

500

|

108

|

62

|

108

|

|

CS-AC-024

|

30

|

37

|

24

|

45

|

|

CS-AC-058

|

600

|

88

|

54

|

145

|

|

CS-AC-025

|

30

|

39

|

24

|

49

|

|

CS-AC-059

|

600

|

100

|

68

|

118

|

|

CS-AC-026

|

30

|

45

|

27

|

39

|

|

CS-AC-060

|

600

|

100

|

65

|

128

|

|

CS-AC-027

|

30

|

46

|

25

|

40

|

|

CS-AC-061

|

750

|

112

|

70

|

132

|

|

CS-AC-028

|

40

|

46

|

30

|

40

|

|

CS-AC-062

|

800

|

113

|

62

|

140

|

|

CS-AC-029

|

50

|

52

|

30

|

50

|

|

CS-AC-063

|

850

|

100

|

68

|

150

|

|

CS-AC-030

|

50

|

52

|

32

|

50

|

|

CS-AC-064

|

1000

|

120

|

75

|

143

|

|

CS-AC-031

|

50

|

50

|

30

|

54

|

|

CS-AC-065

|

1250

|

112

|

75

|

160

|

|

CS-AC-032

|

50

|

50

|

30

|

48

|

|

CS-AC-066

|

1300

|

135

|

83

|

150

|

|

CS-AC-033

|

50

|

56

|

30

|

45

|

|

CS-AC-067

|

1350

|

120

|

80

|

155

|

|

CS-AC-034

|

70

|

56

|

35

|

56

|

|

CS-AC-068

|

1500

|

140

|

90

|

170

|

|

|

|

|

|

|

|

CS-AC-069

|

2000

|

150

|

93

|

200

|

Technical parameters of alumina ceramics crucibles

|

material

|

aluminium oxide

|

|

terms

|

unit

|

AL997

|

AL995

|

AL99

|

AL95

|

|

content

|

/

|

99.70%

|

99.50%

|

99.00%

|

95%

|

|

color

|

/

|

ivory white

|

ivory white

|

ivory white

|

ivory white white

|

|

gas tigntness

|

/

|

air proof

|

air proof

|

air proof

|

air proof

|

|

density

|

g/cm3

|

3.94

|

3.9

|

3.8

|

3.75

|

|

straightness

|

/

|

1‰

|

1‰

|

1‰

|

1‰

|

|

hardness

|

Moh's hardness

|

9

|

9

|

9

|

8.8

|

|

water absorption

|

/

|

≤0.2

|

≤0.2

|

≤0.2

|

≤0.2

|

|

bending strength (20℃)

|

Mpa

|

375

|

370

|

340

|

304

|

|

compressive strength (20℃)

|

MPa

|

2300

|

2300

|

2210

|

1910

|

|

thermal coefficient of expansion (20℃ to 800℃)

|

10-6/℃

|

7.6

|

7.6

|

7.6

|

7.6

|

|

dielectric strength (5mm thickness)

|

AC-kv/mm

|

10

|

10

|

10

|

10

|

|

dielectric loss 25℃@1MHz

|

/

|

<0.0001

|

<0.0001

|

0.0006

|

0.0004

|

|

dielectric constant 25℃@1MHz

|

/

|

9.8

|

9.7

|

9.5

|

9.2

|

|

mass resistivity 20℃ / 300℃

|

Ω*cm3

|

>1014 / 2*1012

|

>1014 / 2*1012

|

>1014 / 4*1011

|

>1014 / 2*1011

|

|

long time usage temperature

|

℃

|

1700

|

1650

|

1600

|

1400

|

|

heat conductivity 25℃

|

W/(m*K)

|

35

|

35

|

34

|

20

|

Points of Alumina Ceramic Crucible:

1.High alumina purity ,Al2O3 90% 95% 99% 99.5% 99.7% for choose,good corrosion resistance.

2.High temperature resistance,1600C in long use,1800C in short use.

3.Good thermal shock,no easy to crack.

4.High slip casting density.

Why choose us

1. Support custom-made ceramic crucible, whatever, it's prototyping project or cost down the program.

2. With over than 30 years OEM, ODM manufacturing experience.

3.With in-house comprehensive production equipment from forming to a secondary process.

4.Free samples available for the stocked ceramic crucible

Shipping: We do international shipping for clients.

Special offer: Most of our ceramic products are produced to OEM order, please mark clearly height, bottom diameter, top diameter, wall thickness and any special requirements i.e. lips etc. To speed up quotations please supply a drawing and if appropriate, the name of the system in which they are to be used.