2.0-5.0 Ton Hydraulic Manual Pallet Truck MT Series

Hydraulic Hand Pallet Truck is through the manual operation of the hydraulic pump, through the control valve, to achieve the lifting and lowering of the fork. In the handling process, the operator controls the direction and walking speed through the handle, and uses the walking wheel to move the carrier on the ground, so as to achieve the short-distance transportation and loading and unloading of goods. Hydraulic Pallet Truck Jack, which is easy to operate, relying on manual hydraulic pump drive, through a simple handle operation, you can easily achieve the lifting and handling of goods. Manual Pallet Truck, Strong flexibility, compact body, small and lightweight, small turning radius, able to shuttle freely in narrow channels. According to the customer's work needs and scene requirements, the body structure can be customized, the body material can be customized, the lighting device can be configured, the electronic weighing system.

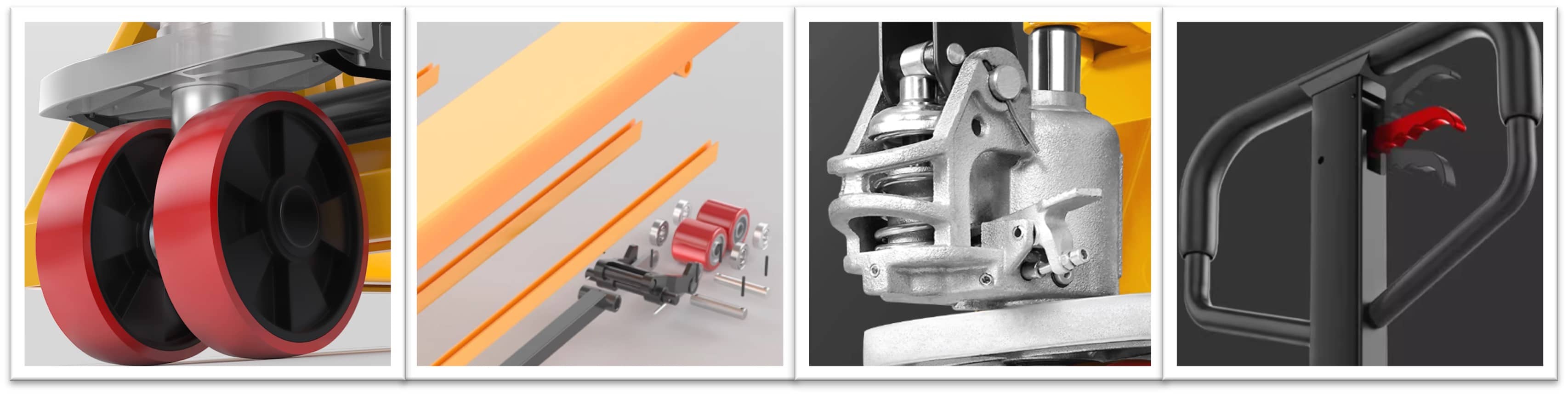

Details & Advantages

▶ Structural Design

1) Compact and Lightweight: The overall structure is compact, the body is small, and the weight is relatively light, making it easy for operators to push and maneuver.

2) Ergonomic Design: The handle is designed with an easy-to-grip shape and material, and the operating height is moderate. The operator's arms and body can maintain a natural and comfortable posture, reducing fatigue caused by long-term operation and lowering the labor intensity.

▶ Hydraulic System Design

3) Efficient and Labor-saving: It adopts a hydraulic drive system. Through manual operation of the hydraulic pump, the principle of liquid pressure transmission is used to achieve the lifting of goods. Just press the handle gently, and a large lifting force can be generated.

4) Stable and Reliable: The hydraulic system can provide a stable pressure output. At the same time, the hydraulic system is equipped with safety devices such as safety valves and pressure limiting valves, which can effectively prevent system overload.

▶ Fork Design

5) Strong Versatility: The size and shape of the forks are usually designed as standard specifications, which can be adapted to various common pallets, having wide versatility. Moreover, the front end of the forks is designed in an arc shape, making it easy to insert into the bottom of the pallet, and the operation is convenient and quick.

6) Strong and Durable: The forks are made of high-strength steel and have undergone strict heat treatment and surface treatment processes, having high strength and rigidity, and being able to withstand a large load without deformation.

▶ Wheel Design

7) Flexible Steering: The front wheels usually adopt a swivel wheel design, which is flexible in steering, enabling the pallet truck to achieve rapid steering and precise positioning in a narrow space. The rear wheels adopt fixed wheels, providing stable support and driving direction control, ensuring the stability and straight-line driving performance of the pallet truck during driving.

8) Wear-resistant and Shock-absorbing: The wheels are made of materials with good wear resistance, such as rubber, polyurethane or nylon, which can adapt to different ground conditions, reduce the wear of the wheels, and extend the service life.

FAQ

1) What is terms of payment?

T/T, 30% deposit, 70% balance paid before shipment.

2) What is the inspection method?

Product photos, packaging, videos, and any other inspection methods required by customers.

3) How is the product packaged?

Naked, packaging film, wooden box, iron frame, and other required packaging methods.

4) How long is the warranty period?

18 months. Spare parts are provided free of charge during the warranty period.