Filament wound series is the first choice and highest level, they are manufactured by filament winding machine and applied with self-developed yellow color high temp resin, the advanced manufacture tech and layup design make filament wound series more superior than other Chinese carbon rims. They have been offering to some famous riders and big brands in the world.

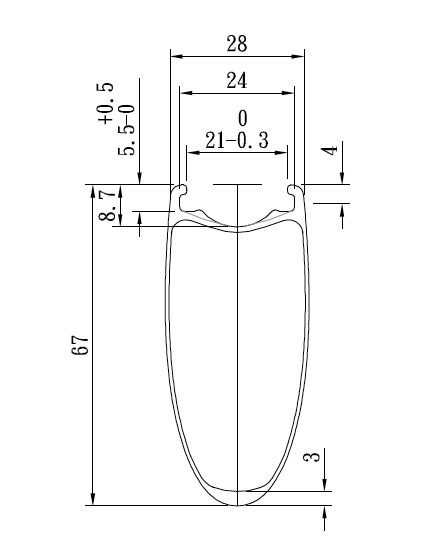

Product Specs

Material: Toray T700 (Imported from Japan / Korea)

Size: 700C

External Width: 28mm

Internal Width: 21mm

Depth: 67mm

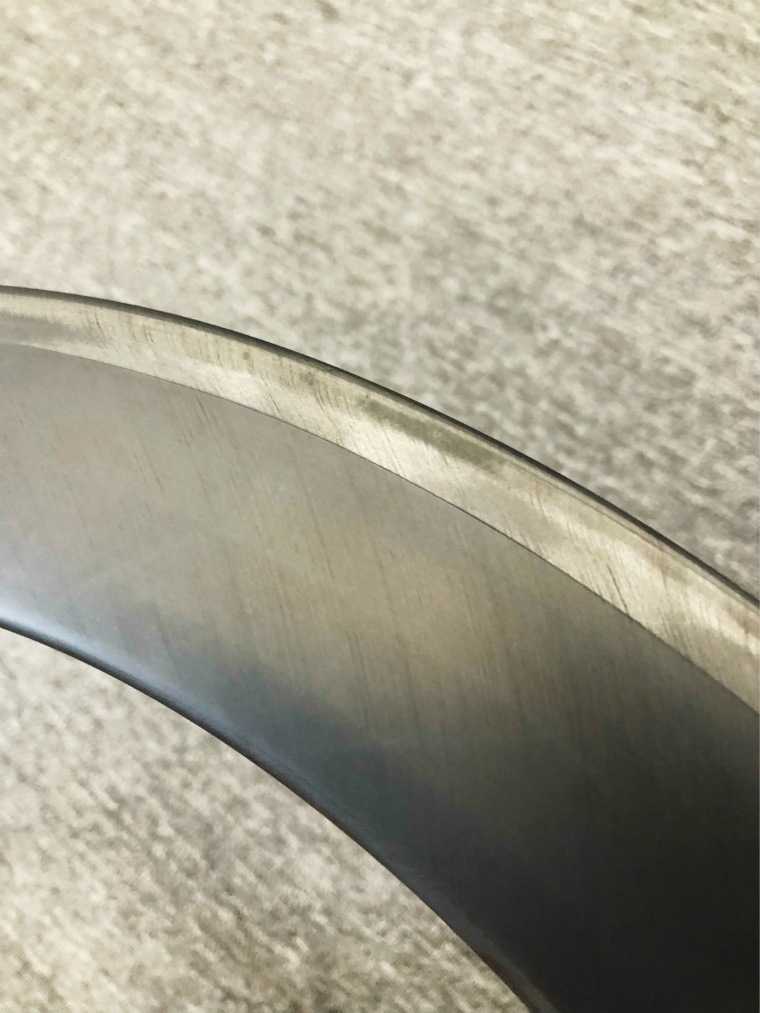

Finish: UD Matt / UD Glossy (Customized with your logo artworks)

Spoke count: 16-32H

Nipple hole: External / Internal

Weight: 550g+/-15g

ERD: 504.2mm

Rider weight limit: 120KG

Max tire pressure: 125PSI

Max spoke tension: 140KGF

Flatness: ≤0.2mm

Roundness: ≤0.3mm

Highlights

- Patented filament winding process to ensure that each carbon fiber layer can be distributed evenly and bonded tightly, enabling its strength to reach a maximum value. Also machine managed process can avoid the random layup errors and result higher accuracy & precision.

- Patented self-developed 240 degree high temperature resin, tested by DMA / DSC in house.

- Carbon fiber pre-preg weaving in house, impregnating with own HTG resin system.

- Using hard mandrel to shape the rim bed, it stays very well under curing without movement, results a much more precise clincher hook. (While others use silicone or three-piece molds)

- X-Ray machine to inspect the inside layup structure to guarantee the strength from every aspect.

- First time 220 degree molding; Second time 230 degree baking 8 hours; Third time 230 degree baking 6 hours.

- Full inspection of tire pressure test at 140psi for every rim.

- Rim profile designed by American composite expert who use CFD work to optimize the aerodynamics.

- UCI / ISO test standard; Wind tunnel test in Arizona USA.