29er Full Suspension Enduro All-Mountain Bike Frame

-

Type: 29” 2.6”full suspension AM MTB frame

-

Size: 15..5”/17.5” / 19”

-

Head Tube: Tapered 1-1/8’’ - 1-1/2”(Upper 44mm,lower 56mm,FSA-NO.57E)

-

Bottom Bracket: BSA-73mm

-

Seat Post: 31.6mm

-

Max Tire Clearance.: 29”*2.6”/650B*3.0”

-

Max Compatible: 32T

-

Travel : 160mm

-

Rear Shock: 185mm*55mm(30*185*57 standard mount)

-

Weight:2200g+/-50g(17.5”)

-

Finish: UD/Color

-

Test Standard: ISO-4210-EN15194

Bearing Size

Many kinds of frame size for customer more option,please send email to sales@tourdecycling.com for more frames size geometry.

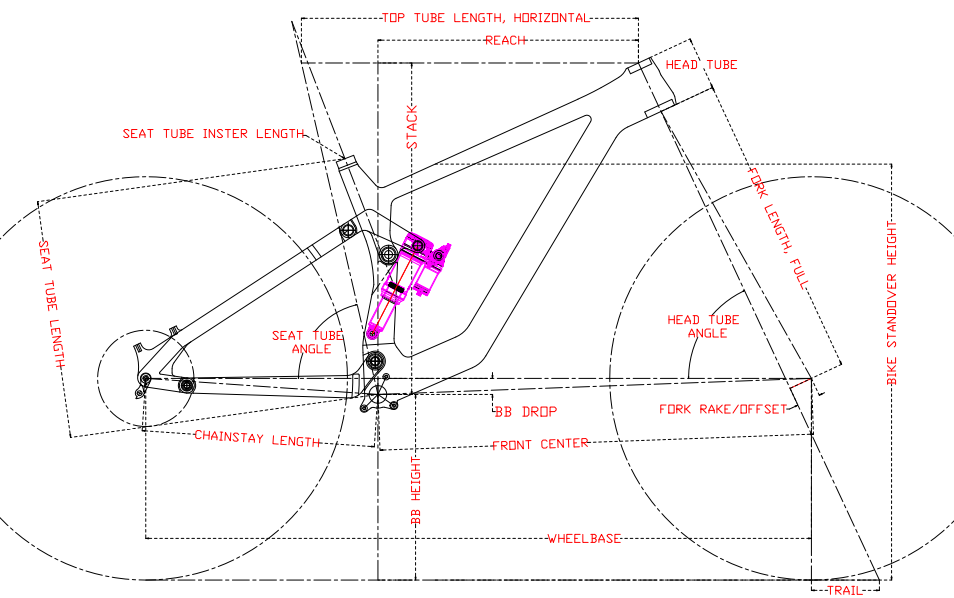

Size

|

15.5"

|

17.5"

|

19"

|

|

Stack

|

615

|

620

|

629

|

|

Reach

|

458

|

487

|

505

|

|

Head Tube Angle

|

65

|

65

|

65

|

|

Head Tube Length

|

95

|

100

|

110

|

|

Seat Tube Angle

|

77

|

77

|

77

|

|

Top Tube Length

|

600

|

630

|

650

|

|

BB Drop

|

30

|

30

|

30

|

|

Rear To BB Center

|

435

|

435

|

435

|

|

Fork To BB Center

|

780

|

810.9

|

833.3

|

|

Fork Built Height

|

571

|

571

|

571

|

|

Fork Rake

|

44

|

44

|

44

|

|

Wheel Base

|

1213.4

|

1244.3

|

1266.8

|

Compatible Rear Shocks (185*55mm trunnion mount) and Bushing Kits(30*10mm)

Rear shock not compatible with Coil shocks, e.g. FOX DHX2 since the coil diameter was beyond space for normal shock area.

Mountain Bike Frame Geometry

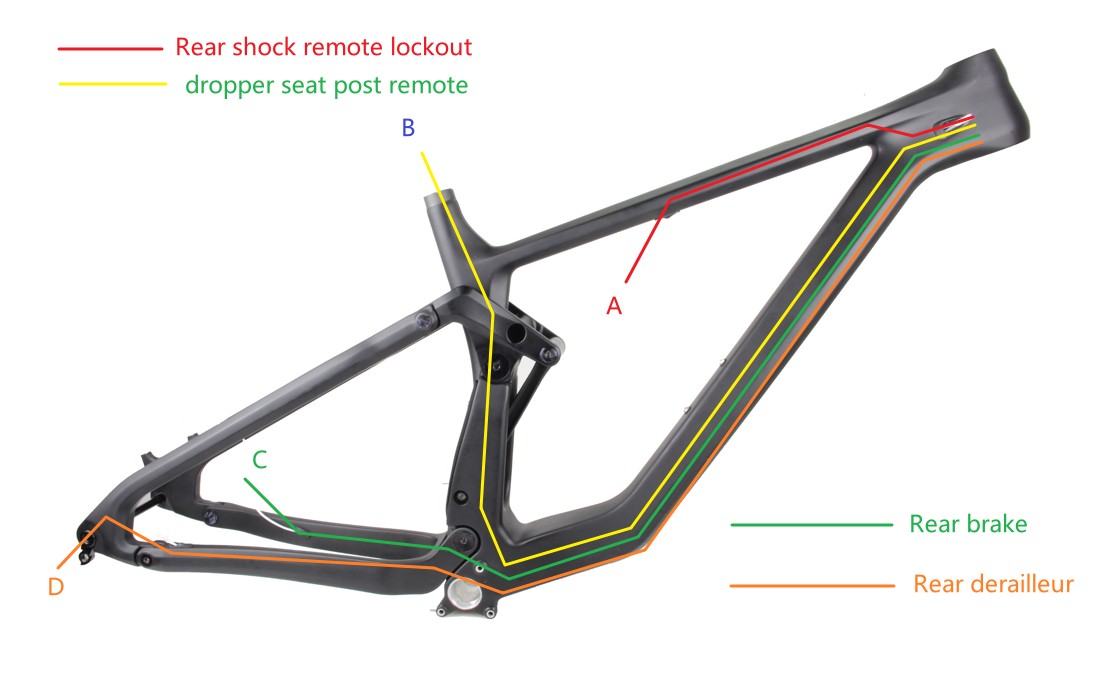

Full suspension bike frame cable routing instruction

Cable A: for rear shock remote lockock

Cable A: for rear shock remote lockock

Cable B: for dropper seat post remote control

Cable C: for rear brake

Cable D: for rear derailleur

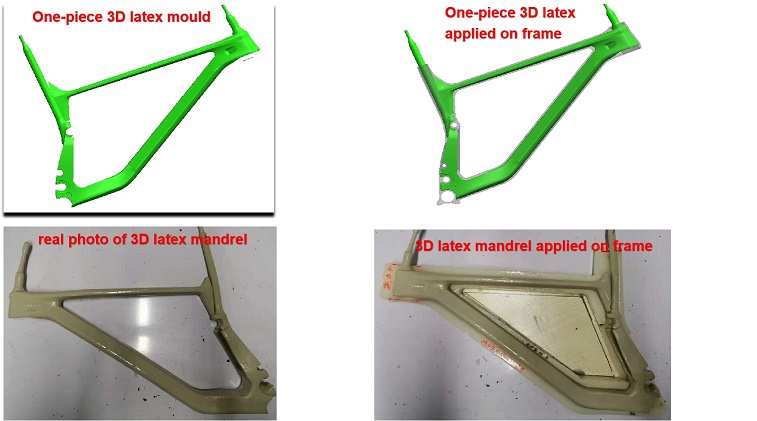

Technology we use on Enduro frame production

Use the newest one-piece latex 3D mandrel and molding technology.

Such technology helps to optimize the orthodromic and strength of carbon fiber, and avoid wrinkle inside (wrinkle is a key factor that may cause crack).Even using the same material, the strength is improved 30%.

In order to protect the chainstay, we have made a special chain stay rubber protector for the frame.

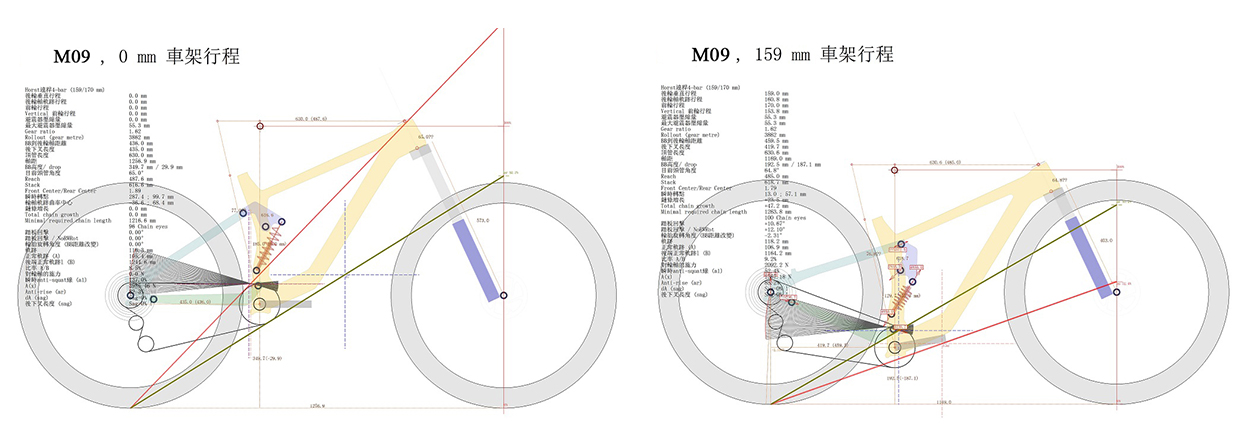

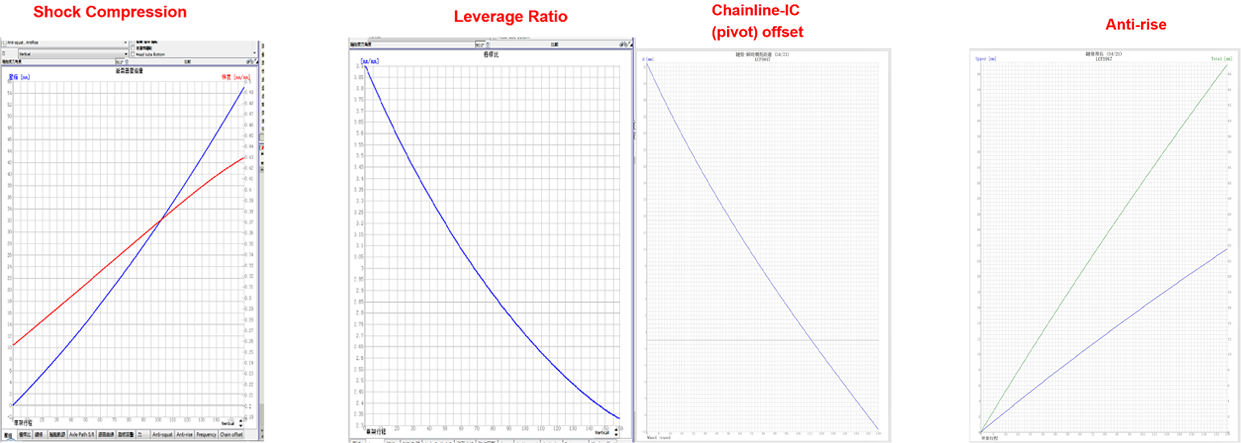

Simulate data details from 0~159mm travel

Below curve data was simulated for TDC-FS909 Enduro frame

Build complete bike of TDC-FS909 Enduro bike frame

TECHNOLOGY

|

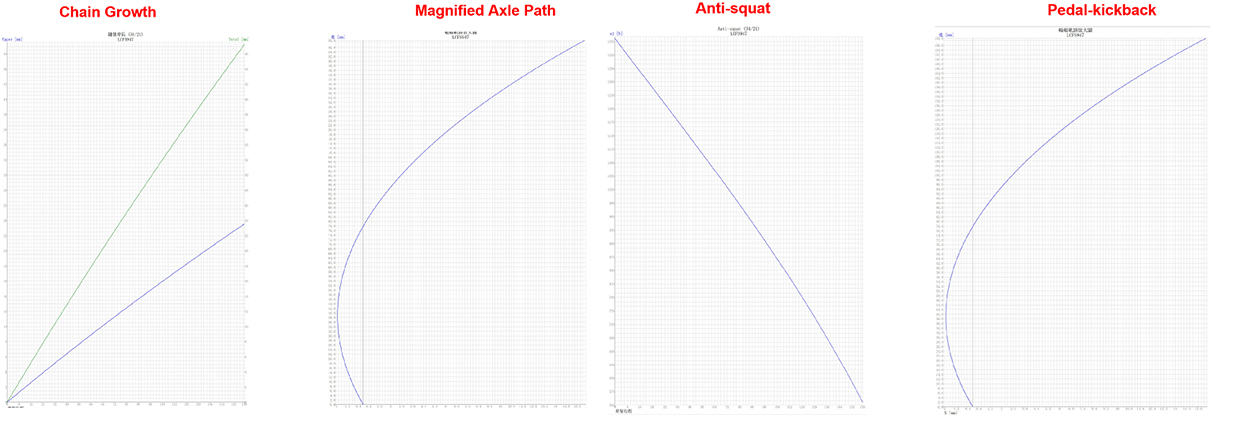

Italy Design Team

we invited Italy professional engineer to develop new moulding each year. More than 10 years design experience can supply more accurate design which is developed according to the customer’s requests and specifications, focusing on the targets and providing functional solutions.

|

|

|

3D latex mandrel technology

we added new 3D latex mandrel technology. 3D latex mandrel technology than traditional EPS or airbag technology can make frames more smooth without wrinkle inner wall.

|

|

Carbon Fiber Material

Premium Japan Toray T700/T800 carbon fiber is used in our carbon bike frame.

Combining with stable resin system to make consistent quality and light weight frame.

|

|

Lab Test

All tour de cycling carbon frame are rigorously tested under international standard ISO4210/EN15194.We will also be sent sample to the 3rd External Organization for SGS testing upon customer’s requirement. All new frames will be tested at least 10% more strictly during the development phase on the basis of EN15194 or ISO4210, thus it can ensure the safety of all products.

|

|

2-Year Warranty

We have very strict mass production management system, IQC, PQC, OQC and Lab Testing process. We insist on making high quality.

For all carbon rims and carbon wheels sold by ProX, 2 years’ quality warranty is offered (starting from the date of package being signed).

Click Warranty to see more details in another page.

|

Why choose us ?

Tour De Cycling has more than 17 years of production experience in carbon frame developing and manufacturing.. Our factory has mature technology and patents, can be customized design for brand companies, and provide OEM services. More than 100 kinds of frame products have been developed and produced, and more than 95% of them are exported overseas.

FAQ:

Q1: Wonder if you accept small orders?

A1: Yes, we accept small trial orders. Besides, trial order's product quality is the same to massive production.

Q2: Can you send samples to test?

A2: Sure, sample is welcomed, while the sample's fare and freight at your cost.

Q3: Can you do OEM/ODM for me?

A3: Yes, both is available, besides, we have design department, if you have problems, we can help solve them.

Q4: How can I place the order?

A4: Firstly, confirm PI and pay deposit,then we will arrange sample and massive production. After finished production, plz pay the balance before shipment. Then delivery the goods.