6201 Silicon Carbide Bearings Specification :

|

Bearing Type

|

Ball

|

|

For

Load Direction

|

Radial

|

|

Construction

|

Single Row

|

|

Seal

Type

|

Open,ZZ,RS

|

|

Part

Number

|

6201

|

|

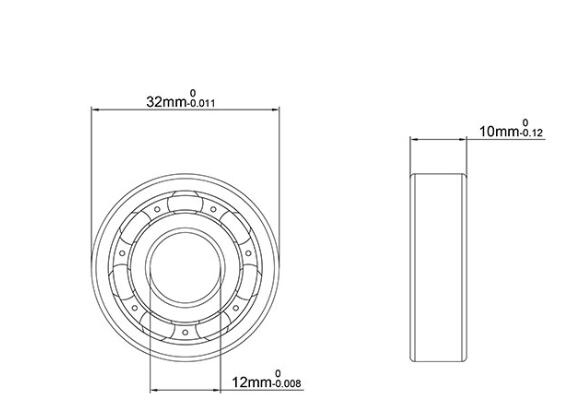

Bore

Dia (d)

|

12 mm

|

|

Bore

Dia Tolerance

|

-0.008mm to 0

|

|

Outer

Dia (D)

|

32mm

|

|

Outer

Dia Tolerance

|

-0.011mm to 0

|

|

Width

(B)

|

10mm

|

|

Width

Tolerance

|

-0.120mm to 0

|

|

Ring

Material

|

Silicon Carbide Ceramic

|

|

Ball

Material

|

Silicon Carbide Ceramic

|

|

Cage

Material

|

Full balls without cage

|

|

Seals

Material

|

PTFE

|

|

Dynamic

radial (Newtons)

|

1360

|

|

Static

radial (Newtons)

|

610

|

|

Max

Speed (X1000 RPM)

|

16.2

|

|

Lubrication

|

Without

|

|

Shaft

Mount Type

|

Press Fit

|

|

Temperature

Range

|

-80° to 1200 ℃

|

|

ABEC

Rating

|

ABEC-1

|

|

Radial

Clearance

|

0.0000 to 0.0005"

|

|

Weight

(g)

|

14.8

|

Full Balls Silicon Carbide Ball Bearings Pictures :

SIC Ceramic Ball Bearings Features :

1).High speed bearings:12000rpm--75000rpm

2).High temperature-resistant bearing:100°C--800°C.It can been applied in kiln,plastic,steel and other equipments that can bear high temperature

3).Corrosion-resistant bearings

4).Electric-insulated bearings

5).Vacuum bearings:self-lubricating without

Ceramic SIC Bearing Application :

Full ceramic sic bearing could be used in following industries: chemical, semi-conductor, valve & pump, food, electronic, medical, vacuum, refining, insulation, etc.

Note:

Full ceramic bearing is not suitable for heavy loading, impact loading and variable loading application.

Ceramic Material Comparison:

Material: ZrO2, Si3N4, SiC and Al2O3, etc.

1.ZrO2 Full Ceramic Bearing

Zirconium oxide ceramic bearing(ZrO2):the rings and balls are all zirconium oxide ceramics with cages made by PTFE,nylon strengthened by glass fibles.

2. Si3N4 Full Ceramic Bearing

Full ceramic bearing made with Si3N4 have some better performance than Zr02, the rings and balls made by full ceramic material: Si3N4, as a standard constructure, the cage made by PTFE, generally we also made the cage with GFRPA66-25, PEEK, PI, Phonemic Textiles Tube, etc.

Compared with the material of ZrO2, the Si3N4 ceramic bearings could endure heavier load and could be used in higher temperature environment.