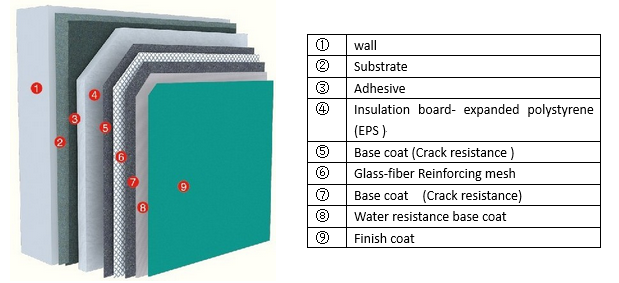

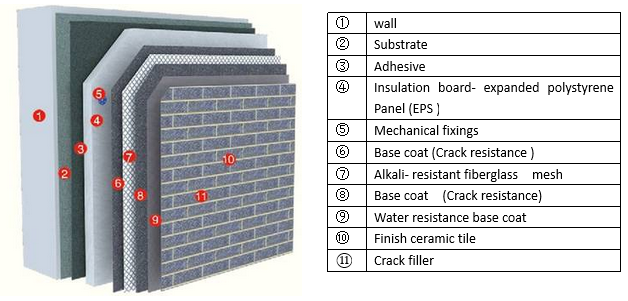

About EIFS

EIFS means Exterior Insulation and Finish System.

Alkali-resistance fiberglass mesh, HPMC, 3.Re-dispersible polymer powder, PP Fiber, Wood Cellulose Fiber, Insulation Anchors.

1. Alkali-resistance fiberglass mesh

It is designed for use as a reinforcing element of the external plaster layer in wet-type facade insulation.

1) Application:

- Restoration and renovation of facades;

- Waterproofing layer of foundations and roofs.

Facade fiberglass mesh is characterized by high density, stiffness and durability. Its application for reinforcement of stuccos surface layer permits to reduce stresses arising due to changes in temperature and humidity, as well as to improve vandal-proof resistance thereof.

Characteristics:

Density: 160 g/m2 (The density should be ≥130g/m2)

Mesh width: 4 x 4 mm

Roll length: 1 x 50 m

2). Different specification Alkali-resistance fiberglass mesh for different use

A. Inner insulation for exterior wall: 3 x 3 x 45g/m2, 5x5 x80g/m2

B. EIFS: 5 x 5x130g/m2 5x5x145g/m2 4x4x160g/m2

C. Polystyrene Powder Particles Exterior Insulation System: 5x5x160g/m2

D. Exterior wall ceramic tile surface EIF 3x7x300g/m2

3) How to identify the quality of alkali resistant glass fiber cloth?

A. The bad quality for the fiberglass uses recycled old glass to made.

B. It is rough work, insufficient length, lack gram, easy broken while you fold one or two time, the contact point is not strong, easy to shift, easy to stab the skin.

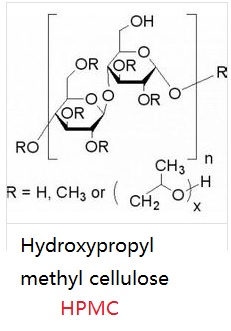

2. HPMC

Application

•Water-based Paint

• Detergent

• Base Coat Manual Plaster

• Top Skim Coat Manual Plaster

• Tile Adhesive

• Tile grout, Joints and Crack Fillers

• Gypsum Manual Plaster

• Extruded Cement Panels

• Exterior Insulation and Finish System (EIFS)

• Self-leveling Compound

Specification

|

Item

|

Unit

|

HPK

|

HPF

|

HPE

|

|

Gelation temperature

|

C

|

70 - 90

|

62 - 68

|

58 - 64

|

|

Moisture content

|

%

|

Max. 6

|

Max. 6

|

Max. 6

|

|

pH value

|

4 - 8

|

4 - 8

|

4 - 8

|

4 - 8

|

|

Viscosity, NDJ-8S,

2% solution (20 C)

|

mPa.s

|

320 -

240.000

|

320 -

240.000

|

320 -

240.000

|

|

Viscosity, Brookfield RV,

2% solution (20 C)

|

mPa.s

|

320 -

78.000

|

320 -

78.000

|

320 -

78.000

|

Avoid contact with skin and eyes.

Key properties

- Maintain liquidity, to improve retention

- Improve bond strength, improve anti-slip performance

- Good construction performance stability

- Increased water demand

- Improve the mortar wetting

- Anti-hanging

Packaging and Storage

A. Standard Packing: In 25kg paper bags inner with PE bags

B. Big Bag or other special packages are possible on request.

Store it in a cool, dry place below 30°C and protected against humidity and pressing, since the goods is thermoplastic, storage time should not exceed six months.

Transport

Handle with care to avoid breakage when moving. Keep from moisture when transporting. This

product is non-toxic, non-irritating, no-combustible.

Safety information:

The above date is in accordance with our knowledge, but don’t absolve the clients carefully checking it all immediately on receipt. To avoid the different formulation and different raw materials, please do more testing before using it. We reserve the right to alter our product and without informing in advance.

3. Re-dispersible polymer powder

Product Data

Properties

* supply high flexibility

* Increase adhesion strength

* improves workability

* prevents cracks

* reduce water absorption

Application range

*Exterior wall plaster mortar

*Exterior wall flexibility putty

*Decorative mortar

*High flexibility cement

Packaging:

A. Standard Packing: In 25kg paper bags inner with PE bags

B. Big Bags or other special packages as per clients’ request.

Storage:

Store it in a cool, dry place below 30°C and protected against humidity and pressing, since the goods is thermoplastic, storage time should not exceed six months.

Safety information:

The above date is in accordance with our knowledge, but don’t absolve the clients carefully checking it all immediately on receipt. To avoid the different formulation and different raw materials, please do more testing before using it. We reserve the right to alter our product and without informing in advance.

4. PP Fiber

Application range

- Projects like concrete road, bridge, airport road and factory floor which strictly require cracking resistance.

- The wall of tunnels, mines, roofs and reservoir projects with special construction.

- River courses and dams, etc.

- Military defense works, dock banks and piers, etc.

Key properties

- Increase seepage resistance

- Prolong endurance

- Improve steel protection

- Increase cracking resistance

- Increase fire resistance

- Strengthen spurt & fatigue

- Improve tensile, bending & folding strength

- Improve plastic deformity

- Strong acid & alkali resistance and good endurance

Packagingand Storage

A. Standard Packing: inner is 0.9kg or 1.0kg/PE small bag

outer are 18 or 20 Small bags per woven bag.

B. Big Bag or other special packages are possible on request.

To be stored in its closed original packaging, keep cool and dry, avoid humidity.

Safety information:

The above date is in accordance with our knowledge, but don’t absolve the clients carefully checking it all immediately on receipt. To avoid the different formulation and different raw materials, please do more testing before using it. We reserve the right to alter our product and without informing in advance.

5. Wood Cellulose Fiber

Key properties

It can make the concrete and some dry-mix mortars:

unti-cracking,

water retention,

anti-shrinkage

anti-slag

Specification

|

Color

|

Gray

|

Off-white

|

|

Model

|

XM-01

|

XM-02

|

|

Bulk weight (appro.) (g/l)

|

210

|

190

|

|

Package(kg/bag)

|

15

|

20

|

15

|

20

|

|

Fiber length

|

300um

|

300um

|

|

Application

|

EIFS Compounds Mortars Cement & lime Plaster, Skim coat,

stucco & adhesive mortars, Self-leveling & Paints.

|

|

Moisture

|

<5.0%

|

|

pH Value

|

7.5+1

|

|

Water retention

|

Approx.600%

|

6. Insulation fixings, Insulation anchors

Specifications

|

Type

(mm-mm)

|

Length (mm)

|

Drill diameter (mm)

|

Min depth or drill (mm)

|

Min anchor depth (mm)

|

Max usable length (mm)

|

|

8-80

|

80

|

8

|

90

|

40

|

40

|

|

8-90

|

90

|

8

|

100

|

40

|

50

|

|

8-100

|

100

|

8

|

110

|

40

|

60

|

|

8-120

|

120

|

8

|

130

|

40

|

80

|

EIFS parameters(Finish coating as surface)

|

Testing Item

|

Peformance Index

|

|

Water absorption(g/㎡)

|

Dip water24h≤500

|

|

Impact strength/J

|

Common type

|

3J

|

|

Enhancing type

|

10J

|

|

Anti-wind pressure value

|

Not less than the wind load in the disgning of the project.

|

|

Freeze - thaw resistance

|

No crack, hollowing, blistering, peeling.

|

|

Steam wet flow density/(㎡.h)

|

≥0.85

|

|

watertightness

|

No water in the inner protection layer of sample

|

|

Weatherability

|

No crack, powder and peeling

|

System component

EPS(Expanded Polystyrene Panel)

|

Testing item

|

Performance Index

|

Testing Item

|

Performance Indix

|

|

Thermal Conductivity / W/m.k

|

≤ 0.041

|

Water absorptioin/%

|

≤2.5

|

|

Apparent density / kg/m

|

18~25

|

Fire rating

|

B1( nonflammable)

|

|

Tensile Strength Mpa/㎡

|

≥0.10

|

Measurement

|

1200x600mm Thickness 2~10cm

|

Adhesive Mortar

|

Testing Item

|

Performance Index

|

|

Tensile Bond Strength

(with cement mortar)

|

Original Strength/Mpa

|

≥0.60

|

|

Water resistance/Mpa

|

≤4.0

|

|

Tensile bond strength

(with EPS panel)

|

Original strength/Mpa

|

≥0.1,

Interface fracture on EPS panel

|

|

Water resistance/Mpa≥0.1,

Interface fracture on EPS panel

|

|

|

Operational time/h

|

1.5~4.0

|

Alkali-resistance fiberglass mesh

|

Testing items

|

Performance Index

|

|

Unit area weight /g/㎡

|

≥130

|

|

Breaking Strain(longtitude、latitude)/%

|

5

|

|

Alkali-resistant tensile breaking force(longtitude ,latitude)N/50mm

|

≥750

|

|

Alkali-resistant tensile breaking force Alkali-resistant tensile breaking force (longtitude ,latitude)%

|

≥50

|

Surface mortar

|

Testing items

|

Performance Index

|

|

Tensile Bond

Strength

(with EPS panel)

|

Original strength/Mpa

|

≥0.1

Interface fracture on EPS panel

|

|

Water resistance/Mpa

|

≥0.1

Interface fracture on EPS panel

|

|

Freeze –thaw resistance/Mpa

|

≥0.1

Interface fracture on EPS panel

|

|

flexibility

|

Compressive strength/ flexural strength(cement based)

|

≤3.0

|

|

Fracture strain(non cement based)

|

≥1.5

|

|

Operational time/h

|

1.5~4.0

|