Air High Low Temperature Thermal Shock Test Chambers

|

Model

|

GTS-056

|

GTS-087

|

GTS-126

|

|

Test zone size W*H*D(mm)

|

400*350*440

|

500*350*500

|

600*350*600

|

|

Exterior chamber size W*H*D(mm)

|

1500*2050*2120

|

1600*2050*2220

|

1700*2050*2320

|

|

Preheat temperature range

|

+200℃

|

|

Precool temperature range

|

-60℃ -75℃

|

|

Test temperature range

|

+60℃~+150℃; -10℃~-50℃;-10℃~-65℃

|

|

Performance

|

Temperature fluctuation

|

±2℃

|

|

Temperature recover time

|

Within 5 minutes

|

|

Heat up time

|

℃

|

150

|

150

|

150

|

|

min

|

30

|

35

|

40

|

|

Cool down time

|

℃

|

-50 -65

|

-50 -65

|

-50 -65

|

|

min

|

60 70

|

70 80

|

80 90

|

|

Material

|

Exterior chamber material

|

Stainless steel plate+ Power Coated

|

|

Inner chamber material

|

SUS#304 stainless steel plate

|

|

Insulation

|

PU& Fiberglass wool

|

|

System

|

Wind Circulation

|

Sirocco fan

|

|

Heating system

|

SUS#304 stainless steel high-speed heater

|

|

Cooling

|

Imported compressor, finned type evaporator, air-cooling condenser

|

|

Controller

|

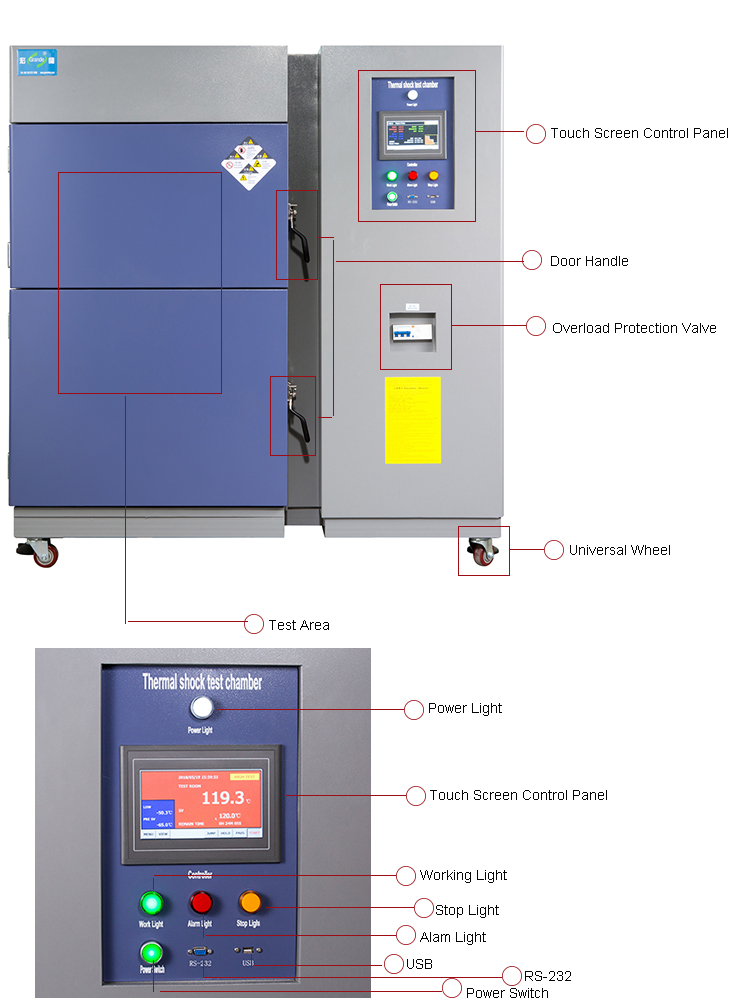

LCD touch panel controller

|

|

Other Components

|

Vaccum glass inspection window, cable port(50mm), control status

indicator lights, chamber lamp,loading shelves(2pcs for free)

|

|

Safty Devices

|

Overheating circuit-breaker,compressor overload protection,control

system overload protection, humidifying system overheating protection,

beakdown indicator light

|

|

Power Supply

|

AC3φ380V 60/50Hz

|

|

Customization

|

Customization of inner chamber size, tempreture&humidity range,ect.

|

Thermal Shock Chamber is used to test the resistance ability of specimen in extreme high and low temperature cycling environment, which is test the chemical change or physical damage due to heat expansion and cold contraction in short period. The machine is applicable to metal, plastic, rubber ,electronic or other materials. It is used to temperature test of electrician materials, household appliances, automobiles, motorcycles, chemicals, and other product components and materials.

Three Zone models have higher performance, three-zone capability, and larger heating/cooling performance that fully benefits from Eco-mode innovations.Equipped with original Japan made true-color touch screen controller with software of both English and Chinese version.It consists of 3 Zones:1,High temperature Zone;2,Low temperature Zone;3,Testing Zone.Adopts unique thermal-break-structure class heating & cooling storage method,then leads hot or cold air to testing zone for thermal shock tests.It can be adjusted shock temperature by switching the hot and cold air flow.

A flexible cabling tube (for monitoring or powering samples) that comes out the side, rather than a moving pipe that sticks out the top.

· A cool-down mode allows the operator to safely remove the samples quickly after a test is completed.

· An option for a window makes checking on the samples easier.

Site requirements:

· Main Power: North American standard 208V (alternate international power: 200V, 220V, 380V, or 415V)

· Cooling water supply

· Quiet operation with sound levels below 65dB

Available options:

· Paperless recorder with color display and CompactFlash storage

· Strip chart recorder

· Computer interface RS-232

· Viewing window

· Additional STT thermocouple inputs

· Additional flexible cable tube

Main Features

1. New perfect precise technology of exterior design, external box adopts cold rolled sheet double sided electrostatic resin high temperature coating, inner box uses the international SUS#304 heat resistant and cold resistant stainless steel seal welding.

2. Thermal insulation layer uses refractory grade high strength PU foam thermal insulation material. Refrigeration system introduction of Japan, Germany advanced energy saving refrigeration control technology, save 20% of energy than conventional devices.

3. Control system and the control circuit adopts imported brand parts.