Product Item: Alumina Ceramic Ball Bearing / Bushing Bearing

Ceramic Bearing we can offer as follows:

|

Type of ceramic bearing

|

|

Ball bearings

|

Roller bearings

|

Taper roller bearings

|

Linear bearings

|

|

Self-aligning ball bearings

|

Thrust ball bearings

|

Needle bearings

|

Spherical roller bearings

|

|

Pillow block bearings

|

Rod end bearings

|

Special bearings

|

Ceramic ball bearings

|

|

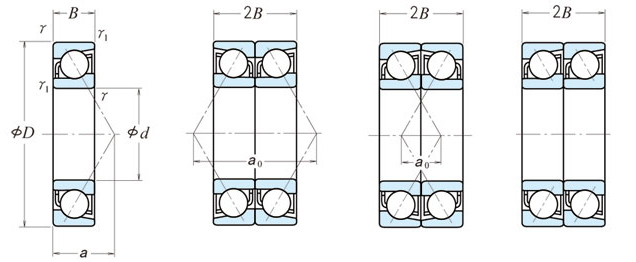

Angular contact ball bearings

|

Slewing bearings

|

Cylindrical roller bearings

|

Sliding bearings

|

Ceramic Bearing Benefits:

1.High loads, high speeds and extreme temperatures are factors

2.Increased bearing life and decreased down time

3.Minimal need for lubrication

4.No cold welding between ceramic balls and races

5.Multi-purpose use in variety of machines and different production lines

6.High efficiency, low weight and small size

Ceramic Bearing Applications:

Ceramic bearings are widely used in electric motors, aerospace applications, performance racing vehicles, laboratory eequipment, under water applications and more. Any application that requires higher speeds, lower friction and longer life are ideal for ceramic hybrid bearings.

Parts of stock ceramic ball bearing Size :

|

Part of available ceramic bushing bearing/ball bearing:

|

|

Itme NO.

|

inner diameter: d

|

outer diameter: D

|

wide: B

|

Basic dynamic load rating

|

Maximum permissible speed

|

Basic static load rating

|

|

|

(φ)

|

(φ)

|

(mm)

|

(N)

|

(rpm)

|

(N)

|

|

CS-BB-01

|

62

|

9

|

13000

|

15000

|

8150

|

-

|

|

CS-BB-02

|

40

|

68

|

9

|

13800

|

14000

|

10200

|

|

CS-BB-03

|

45

|

75

|

10

|

16500

|

12000

|

10800

|

|

CS-BB-04

|

50

|

80

|

10

|

16800

|

11000

|

11400

|

|

CS-BB-05

|

55

|

90

|

11

|

20300

|

10000

|

14000

|

|

CS-BB-06

|

60

|

95

|

11

|

20800

|

9500

|

15000

|

|

CS-BB-07

|

80

|

125

|

14

|

35100

|

7000

|

31500

|

|

CS-BB-08

|

85

|

130

|

14

|

35800

|

6700

|

33500

|

|

CS-BB-09

|

100

|

150

|

16

|

46200

|

5600

|

44000

|

|

CS-BB-10

|

110

|

170

|

19

|

60500

|

5000

|

57000

|

|

CS-BB-11

|

12

|

32

|

14

|

10600

|

20000

|

6200

|

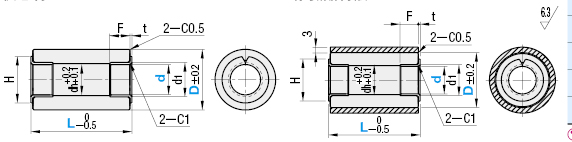

More info of bushing bearing:

The Ceramic bushing bearing action Ring sleeve in the valve application field, bushing within the valve cover, generally uses the advanced ceramics and other corrosion-resistant materials, used for sealing effect. The bushings made of grinding bearings with abrasion-reducing materials are also called bearing bushings and bushings. Usually cast on the inner surface of the bearing, mainly in order to reduce costs, save valuable grinding materials. Thickness 0.5-6mm, for large size or important bearings. Ceramic bushing bearing are mainly to replace the wear of the shaft, in addition to the support shaft operation, friction and wear reduction, vibration reduction role.

Part of available ceramic ball bearing size :

|

Part of available ceramic ball bearing:

|

|

N0.

|

Bore

|

O.D

|

Width

|

Chamfer

|

Load Rating

|

Maximuum Seed

|

Weight

|

|

mm

|

mm

|

mm

|

mm

|

Dynamic

|

Static

|

Grease

|

Oil

|

Kg/pcs

|

|

Cr

|

Cor

|

r/min

|

r/min

|

|

605

|

5

|

14

|

5

|

0.2

|

1.33

|

0.505

|

32000

|

40000

|

0.0035

|

|

606

|

6

|

17

|

6

|

0.3

|

2.19

|

0.865

|

30000

|

38000

|

0.006

|

|

607

|

7

|

19

|

6

|

0.3

|

2.24

|

0.91

|

28000

|

36000

|

0.008

|

|

608

|

8

|

22

|

7

|

0.3

|

3.35

|

1.4

|

26000

|

34000

|

0.012

|

|

609

|

9

|

24

|

7

|

0.3

|

3.4

|

1.45

|

24000

|

32000

|

0.014

|

|

6000

|

10

|

26

|

8

|

0.3

|

4.55

|

1.96

|

22000

|

30000

|

0.019

|

|

6001

|

12

|

28

|

8

|

0.3

|

5.1

|

2.39

|

19000

|

26000

|

0.021

|

|

6002

|

15

|

32

|

9

|

0.3

|

5.6

|

2.83

|

18000

|

24000

|

0.03

|

|

6003

|

17

|

35

|

10

|

0.3

|

6.8

|

3.35

|

17000

|

22000

|

0.039

|

|

6004

|

20

|

42

|

12

|

0.6

|

9.4

|

5.05

|

15000

|

19000

|

0.069

|

|

6005

|

25

|

47

|

12

|

0.6

|

10.1

|

5.85

|

14000

|

18000

|

0.08

|

|

6006

|

30

|

55

|

13

|

0.6

|

13.2

|

8.3

|

12000

|

15000

|

0.116

|

|

6007

|

35

|

62

|

14

|

1

|

16

|

10.3

|

10000

|

14000

|

0.115

|

|

6008

|

40

|

68

|

15

|

1

|

16.8

|

11.5

|

8000

|

11000

|

0.19

|

OME offer:

Most of our ceramic ball bearing produced to order, please mark clearly height, bottom diameter, top diameter, wall thickness and any special requirements i.e. lips etc. To speed up quotations please supply a drawing and if appropriate, the name of the system in which they are to be used.