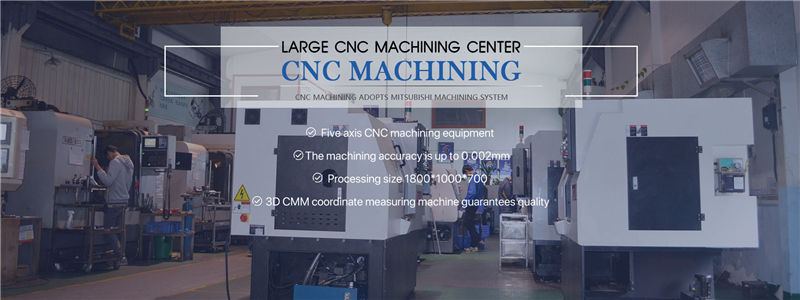

JY Machinery Specializes In CNC Aluminum Machining Products Prototyping

Experienced That Successfully Lead You from Prototype to Production

With more than 10 years of engineering and prototyping expertise, JY Machinery can help you create aluminum prototypes and

custom aluminum parts with our experienced project engineers and machinists to meet your design specification.

We are committed to being your best full-service product development partner. Our CNC aluminum service is striving to

provide you skillful method and decent quality with a professional team whom analyze your project carefully,

figure out the best solution for you and process your custom machined parts in the most efficient way to save your time and cost.

If you are seeking a vendor to provide you high quality aluminum parts CNC machined, JY Machinery is one of the most capable and affordable sources specializing in manufacturing precision machined parts on advanced 3-axis and 5-axis CNC machines.

Contact us today!

The Custom CNC Aluminum Machining Services that We Can Offer:

-

5-axis CNC Machining

-

CNC milling

-

CNC turning

-

Multi-axis milling and turning

-

EDM & Wire Cutting

-

Custom Machine Parts

-

Metal Stamping parts

-

Welding& bending

-

Surfae treatment

-

Assembling service

Aluminum Material Grade Avaibale:

|

Aluminum Grade

|

MaterialDescription

|

|

Aluminum

6061

|

This grade is mainly contains magnesium and silicon, so it concentrates the advantages of the aluminum of 4000 series and 5000 Series,6061 is a cold-treated aluminium forging product, which is suitable for applications requiring high corrosion resistance and oxidation resistance. It has good usability, easy coating and good workability.

|

|

Aluminum

7075

|

This is commonly known as "super hard aluminium",one of the highest strength aluminum alloys.Good mechanical properties and anodize reaction,but it is not weldable and has limited resistance to corrosion ,it is ideally used for highly stressed parts,, representative uses are aerospace, die processing, mechanical equipment, tooling fixtures, especially for manufacturing. Aircraft structures and other high-stress structures requiring high strength.

|

|

Aluminum

6063

|

Commonly known as an architectural alloy. It is suitable for all kinds of industrial structural parts with high strength and corrosion resistance, such as trucks, tower buildings, ships, trams, railway vehicles, furniture, machinery parts, precision die manufacturing, electronic parts and precision instruments, SMT, PC board soldering tin carrier electronics, etc.

|

|

Aluminum

5052

|

The main characteristics are low density, high tensile strength and high elongation.It can be easily drawn or formed into intricate shapes,Suitable for bending and welding.

|

|

Aluminum

2024

|

The characteristics of aluminium2024 is high hardness,also the content of copper is the highest, about 3-5%. 2024 series aluminium bar most common used for Aviation material, which is not often used in conventional industry at present.

|

Surface Treatment:

Zinc/Nickel/Chrome plating,hot galvanized, painting, powder, coating, anodize, vacuum plating, polishing,

electrolytic polishing, steel blue, sank without electricity nickel, silver-plated, gold-plated, and so on.

What you will get from our here?

* Competitive Price Of CNC Precision Machinery part

* Good Quality Assurance

* In Time Sampling & In Time Shipment

* Quality Guarantee

* Free Sample Can Be Provided Some Time

* Low MOQ

* Reply in 24 hours and fast quotaion

*Small MOQ acceptable

Quality Control:

Quliaty is our culture!To ensure the quality of your manufactured parts, a inspection technician will conduct the following checks for your order:

1. The quantity of parts is in agreement with the amounts specified on the Purchase Order.

2. All part dimensions are in accordance with the supplied technical drawing and/or CAD model

(with the technical drawing taking precedence).

3. All parts have had sharp edges and burrs removed.

4. All thread holes are accounted for and tapped as per the technical drawing

(where applicable as indicated on the Purchase Order).

5. All tolerances are within specification as per the technical drawing

(where applicable as indicated on the Purchase Order).

6. All part surface finishes have been applied and are consistent and free of any chips or scratches (where applicable as indicated on the Purchase Order).

7. Relevant QA/QC documentation is included with the order

(where applicable as indicated on the Purchase Order)

8. All parts are correctly packed to ensure parts are not damaged while in transit

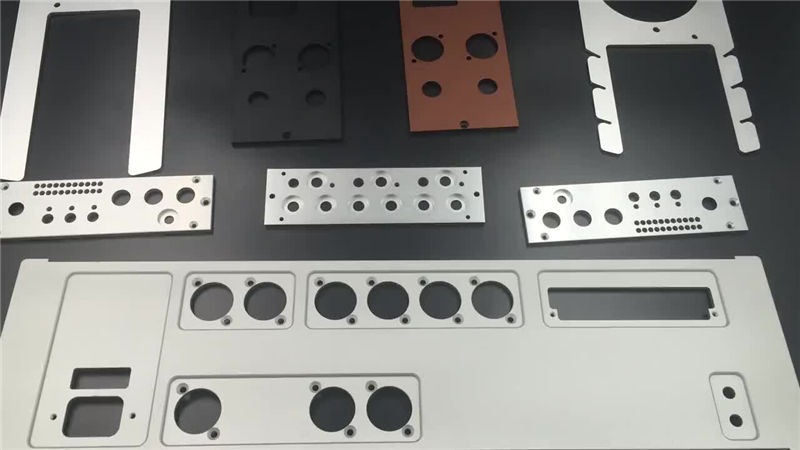

Case Study:

Note:The products shown here is only to present the scope of our business activities. We can manufacture custom parts according to your drawings or samples.

Contact us:

We make CNC parts according to customers' artwork, if you have any parts need to be made, please kindly send 2D and 3D artwork to us. And Please kindly mark dimension, tolerance, material, surface or hot treatment on 2D artwork, then we will according to it to calculate cost for you.

2D artwork format:JPG, PDF, DWG.

3D artwork format: IGS,STP,STEP.

FAQ:

Q:What tolerances can I achieve with CNC machining?

A:Tolerance is the acceptable range of the size determined by the designer according to the shape, fit and function of the part. Unless specifically requested by the designer, the standard tolerance of JY machinery for CNC machining is +/-. 00005 "for metal parts and +/-. 001" for plastic parts.

Q:What raw materials can I use with CNC machining?

A:The raw materials we make process include:

1)Aluminum

2)Stainless Steel

3)Steel

4)Brass

5)Copper

6)Titanium

7)Engineer plastic,such as ABS, acetal, acrylic, PTFE, HDPE, nylon, PE, PEEK, PET,PFA, polycarbonate, polyethylene, polypropylene, polysulfone, polyurethane, PVC, etc.

8)Insulation materials,such as FR4,G10,G11,FR5,GP0-3,Phnolic Paper Laminate,Phenolic Cotton Laminate,etc.

Q:What is 5 axis CNC machining?

A:5 Axis CNC Machining refers to the x, y, and z movement axes plus any two rotation axes. Compared with the common three-axis (x, y, z three degrees of freedom) machining, five-axis machining refers to the processing of parts with more complex geometric shapes, which requires the machining tool to be positioned and connected in five degrees of freedom. The five-axis machine tool can process different sides of the workpiece without changing the position of the workpiece on the machine tool, which can greatly improve the processing efficiency of the prismatic parts.

Q:How do CNC milling machines work?

A:The surface shape of the milling machine is generally composed of straight lines, arcs or other curves. CNC milling is to divide the motion coordinates of the tool and the workpiece into the smallest unit quantity, that is, the minimum displacement. According to the requirements of the workpiece program, the CNC system moves each coordinate by a few minimum displacements, so as to realize the relative movement of the tool and the workpiece to complete the processing of the part.