Aluminum Extruded For Window Frame Catalog

Product Description:

|

Product Name

|

Aluminum Extruded For Window Frame Catalog

|

|

Certification

|

ISO9001,SGS

|

|

Material

|

aluminum alloy

|

|

Thickness

|

General profiles thickness: 0.8 - 5.0 mm;

Anodized protection thickness: 8 - 25 um;

Powder coating color thickness: 40 - 120 um.

|

|

Length

|

3m~6m or more per piece. Customized request available.

|

|

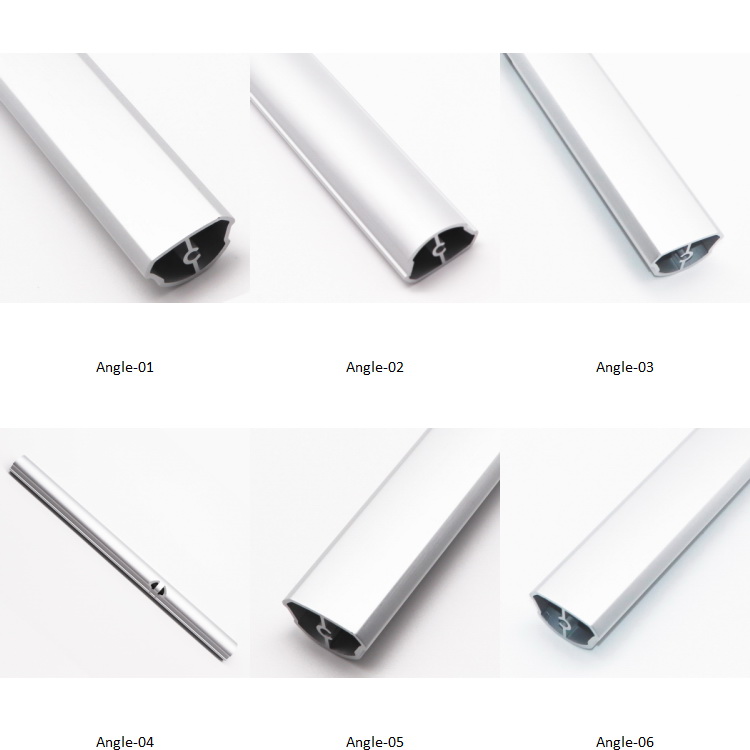

Shape

|

Square, Rectangle, Round, Flat, Angle, T profile etc.

Or as per customer's requirement.

|

|

Surface Treatment

|

Mill, anodized, powder coated, electrophoresis, wood grain, timber, PVDF paint, polish, brushed. As clients require.

|

|

Color

|

Red,black,blue,white,green,Orange,Silver,or customized

|

|

Application

|

Windows and doors, curtain walls, glass wall, furniture, ceiling, kitchen, LED strip, transportation rail, vehicles, motor housing, machine, tent, solar. Industrial profile, Decoration profile etc.

|

|

Deep Process

|

CNC, drilling, milling, cutting, welding, bending, assembling.

|

|

OEM service

|

Available for aluminum profiles

|

|

Characteristics

|

Strong, stylish, durable, corrosion-resistant.

|

|

Packing Details

|

Inside: packed with plastic film to protect each piece.

Outside: Wrap to be bundles by waterproof craft paper or EPE film.

Customized as customers request is available.

|

|

Delivery

|

1-30 working days after payment of aluminum profiles

|

Feature Of Aluminum Extruded For Window Frame Catalog

1. Improve the deformation ability of aluminum. Aluminum is in a strong three-direction compressive stress state in the extrusion deformation zone, and its plasticity can be fully exerted to obtain a large deformation amount.

2. The comprehensive quality of the products is high. Extrusion can improve the microstructure of aluminum and improve its mechanical properties. After quenching and aging, the mechanical properties of the extruded product in the longitudinal direction (extrusion direction) are much higher than those produced by other processing methods. Compared with processing methods such as rolling and forging, the extruded product has high dimensional accuracy and good surface quality.

3. A wide range of products. Extrusion not only can produce tubes, rods and wires with simple cross-section shapes, but also can produce solid and hollow profiles with very complicated cross-section shapes, variable-section profiles with progressively varying sections along the length of the product sections, many of which are Shaped articles cannot be formed by other plastic processing methods. Extruded products are also available in a wide range of sizes, from super-large tubes and profiles with a diameter of 500-1000 mm to ultra-small precision profiles with a cross-section size like a matchstick.

4. Great production flexibility. Extrusion has great flexibility. It can be used to produce different shapes, sizes and varieties of products on the same equipment by changing the mold. The operation of changing the mold is simple, convenient, time-consuming and efficient.

5. The process is simple and the equipment investment is small. Relative to piercing and rolling.Pipe and profile production processes such as hole rolling, extrusion molding has the advantages of short process flow, low equipment quantity and investment.

Company profile

FAQ

01 What's your products range or service?

A: We are specialized in Anodized Oxidation Aluminum Profile, Machining&CNC Processing Centre,Extrusion Aluminum Profiles, and Die Casting Parts

02 Are you a factory or trading company?

A: We are Industrial and Trading Company, our factory covers an area with 1, 5000+square meters, and

03 How can i visit there?

A: We locate in Xiamen, Fujian prov, China Xiamen is a traffc hub city, There are several directinternational flights to Europe, North America, South America and Australia.

o4 What quality control system certifications do you have?

A: We are passed iSo9001: 2015 certificate, which audited by UKAS.

05 Do you have inspection procedures for profiles?

A: Yes, 100% self-inspection before shipping

06 What's the lead time for small order and mass production?

A: 5-10 Working days for small order, and 15-25 working days for mass production of material, the exactly lead time is going to be subject to the actuality.