Different design of standing seam roof panel roll forming machine, tapered standing seam roof machine/ tapered slitting machine/ arc roof bending machine are acceptable

Product Name: Aluminum Sheet Standing Seam Roof Panel Roll Forming Machine

Machine Details

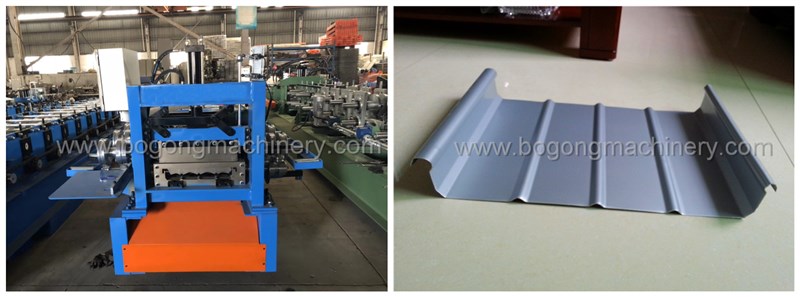

There are many types of standing seam roof panel roll forming machines, see below shape, it is oblique type clip lock type, 14 stations roll forming, this machine frame is wall-plated connect type, each station are connected by square wall plates and locked by screw nuts, compacting strips.

See another type design of standing seam roof roll forming machine, the standing seam roof material is aluminum sheet, so we also call this machine aluminum sheet standing seam roof panel roll forming machine. When make the two pieces of roof panel join together well, we normally need fastener, then seamed the two pieces of standing seam roof by electric seaming machine. By the way, the standing seam roof raw material can be Al-Mn-Mg alloy coil, aluminum sheet, ppgi sheet, galvanized sheet and even copper sheet, it depends on user's local popular and acceptable material.

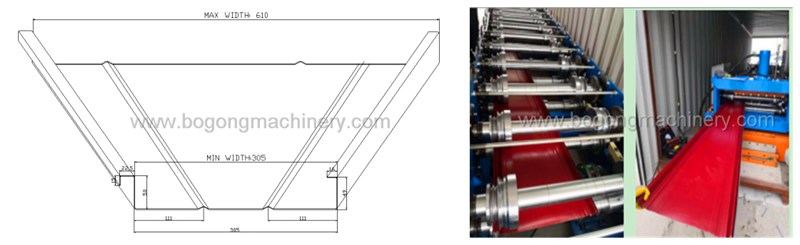

Except straight type standing seam roof panel roll forming machine, we also can customized taped style standing seam roof panel roll forming machine. See below design, one end width is 610mm and other end is 305mm, between 305mm and 610mm width range, the size can be interchangeable according to user's requirements. PLC control system can calculate tapered angle degree after we input panel's two end width and panel length.

Technical Parameters

|

Parameters

|

Specification

|

|

Voltage

|

380V/50HZ/3PH/or customized

|

|

Driving Motor

|

5.5KW

|

|

Forming Steps

|

14 steps

|

|

Working Speed

|

15-20m/min

|

|

Thickness for Steel

|

0.3-0.5mm (Material:PPGI,GI Steel G550)

|

|

Shaft Diameter

|

75mm

|

|

Shaft Material

|

High grade 45# forged steel

|

|

Roller Material

|

G45# steel, CNC lathe,polished and chrome plated

|

|

PLC Cabinet

|

Schneider, Delta

|

|

Encoder

|

Omron

|

|

Sprocket Wheel

|

45 steel high-frequencies quench

|

|

Cut-off System

|

Post cutting, no waste cutting

|

|

Cutting Blade Material

|

Cr12 steel

|

|

Machine Frame Material

|

Fine welded structural steel;

|

|

Roofing Material

|

PPGI, GI steel G330-550

|

|

Painted Color

|

Blue+Orange Or Customization

|

|

Overall Size

|

7000*850*1250mm

|

|

Weight

|

3000KGS

|

One more YX65-425 standing seam roof sheet roll forming machine for reference.Contact with us soon to get more information.