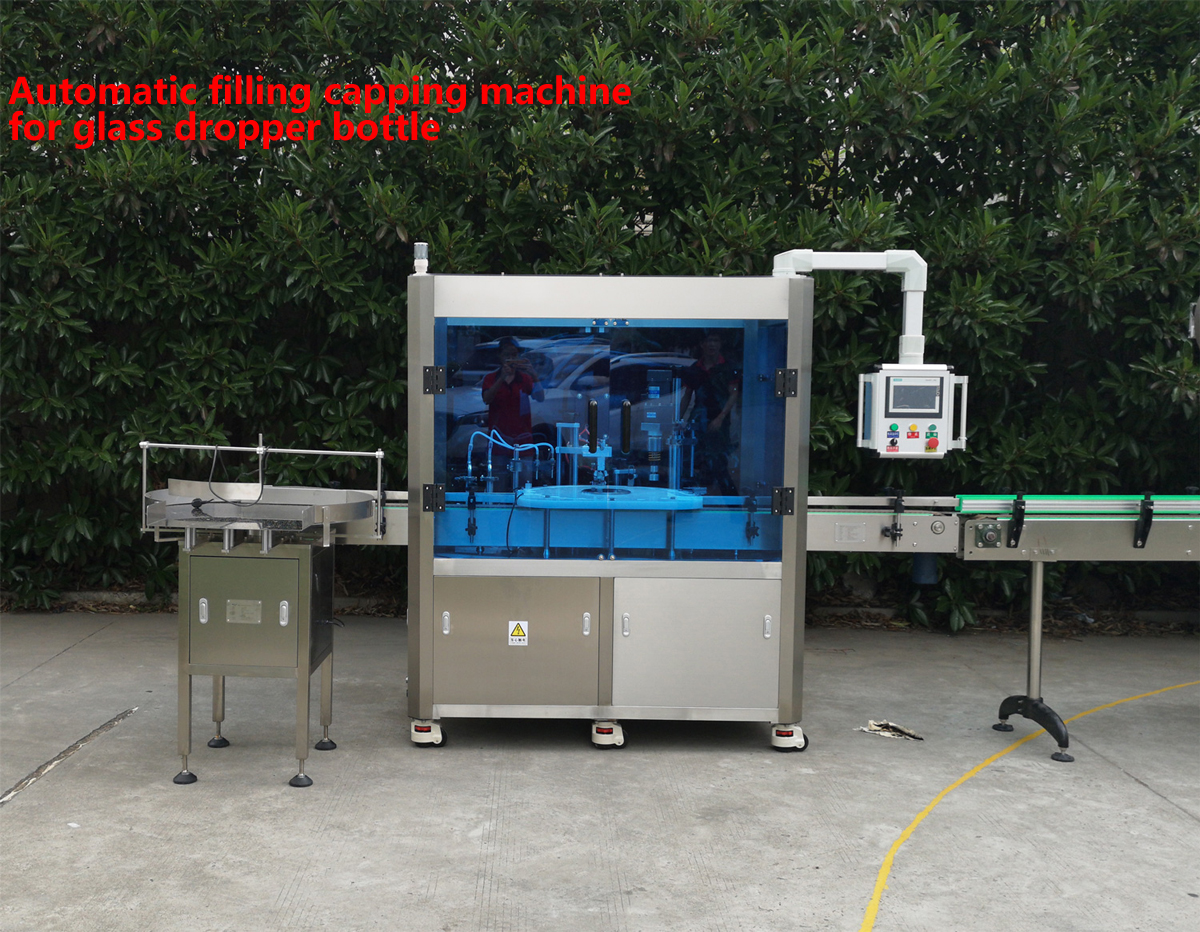

Automatic CBD Oil Filling Capping Labeling Machine Line for Small Glass Dropper Bottle

Application :

- The filling capping and labeling machine is widely used in CBD oil, E-Cigarette, Pharmaceutical, Health Care industries.

- This vial filling capping and labeling machine is suitable for small volume 10-100 ml liquid automatic packing, like CBD oil, Essential oil, E-Cigarette Oil, Eye Drop, Oral Liquid and so on.

Machines Recommended :

- Turn table for feeding bottles

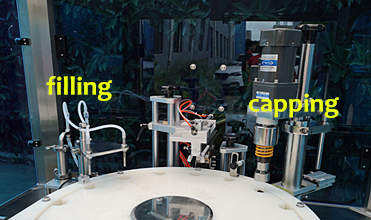

- Automatic filling and capping machine in 1 machine

- Automation round bottle positioning labeling machine with date printer

- Automatic shrink sleeve labeling machine

- Turn table for collecting bottles

Work process:

- Manually put bottles on the turn table

- Bottles conveyed to filling capping machine to fill automatically

- Bottle conveyed to cap automatically after filling

- Automatic labeling or sleeve shrink labeling machine

- Collect bottles with a turn table

the Whole Line technical parameter

- Bottle applied: Round glass dropper bottle or round plastic bottle

- Line speed: 1800-3000 bottles per hour

- Filling volume: 10-100 ml (can be customized)

- Power: about 5KW

- Air pressure and consumption: 0.6-0.8Mpa

Spec and Feature

- The whole machine line is designed especially for 10-100ml liquid filling, capping, labeling

- The line speed is 20-35 bottles per minute

- Filling plugging-in and capping machine in one machine, save space and away from pollution

- Famous branded electrical parts guarantee the line working stable and a longer working life

- Adopts peristaltic pump or piston pump for filling, high filling precision. No bottle, no fill, no drop, no leak

- Touch screen, easy operate and adjust human interface. English operation interface

- The machines can work together smoothly or work alone by PLC control

- The line is easy to install, operate, maintenance, and move

- Suitable for different diameter bottles, just need several minutes change parts for different bottles

- All the machine parts which contact liquid adopt corrosion resisting material and 316 stainless steel

- The machines have emergency stop Button and automatic interrupt device for safe operation

- Labors need: 1-2 workers

- Space for the line: 8000*1500*1900mm

- Power Supply

Machine display:

Project Examples

On-site commissioning and installation