Custom make kinds of roof sheet roll forming machine, shutter door roll forming machine, tile roof roll forming machine, floor deck roll forming machine and other steel roll forming machines!

Product name: Automatic Metal Roof Sheet Crimping Curved Machine Customized Manufacture

Machine Details

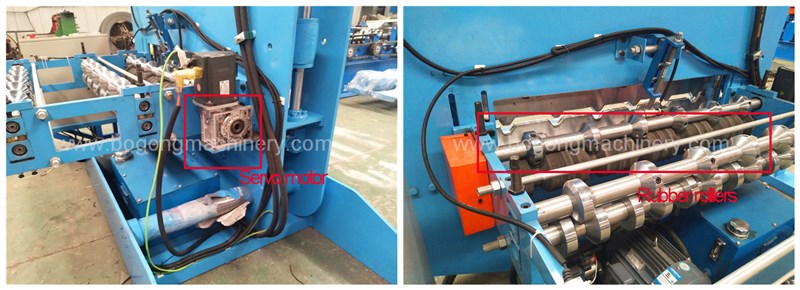

Automatic Metal Roof Sheet Crimping Curved Machine Customized Manufacture is the next assistant machine for metal roof sheet roll forming machine. Our metal roof sheet crimping curved machine is with servo motor for feeding, it can improve the crimping action precision, but the crimping curved action will be done by hydraulic system.

There is rubber material rollers on last feeding station, it is for keep metal roof sheet more better effective, no scrap or no destroy painting.

This Automatic Metal Roof Sheet Crimping Curved Machine is controlled by PLC control system, we can start, stop machines on PLC operation board, also the PLC control system controls this crimp curved roll forming machine work in vertical direction or horizontal direction, if there is any accident, press down the emergency stop soon. The working speed will be tested by encoder, see the encoder touches on roof surface, it can monitor how long the roof sheet has been crimped.

We designed three stations for leading roof sheet into crimping mold on this Automatic Metal Roof Sheet Crimping Curved Machine, the feeding rollers are special designed according roof sheet design to ensure feeding roof sheet into crimping curved mold in straight direction. Another picture are crimping curved roof sheet sample produced by this Automatic Metal Roof Sheet Crimping Curved Machine.

Technical Parameters

|

Parameters

|

Specification

|

|

Voltage

|

380V/50HZ/3PH/or customized

|

|

Driving Motor

|

5.5KW

|

|

Forming Steps

|

3 steps

|

|

Working Speed

|

0-10m/min

|

|

Thickness for Steel

|

0.3-0.6mm

|

|

Shaft Diameter

|

75mm

|

|

Shaft Material

|

High grade 45# forged steel

|

|

Roller Material

|

G45# steel, CNC lathe,polished and chrome plated

|

|

PLC Cabinet

|

Schneider, Delta, Simenz

|

|

Encoder

|

Omron

|

|

Min. crimping radius

|

500mm

|

|

Machine Frame Material

|

Fine welded structural steel;

|

|

Roofing Material

|

PPGI, GI steel G330-550

|

|

Painted Color

|

Blue+Orange Or Customization

|

|

Overall Size

|

3500*1450*1650mm

|

|

Weight

|

1500KGS

|

Video For Reference