VRV linear vibrating screen

------Tailor made for screening multiple materials

Banana screen takes its name from the banana-like arrangement of the screen linings, also known as equal thickness screen. The advantage in comparison to the conventional screens: a much larger feed quantity with the same screen area. It is mainly used for coal classification, desliming, de-watering and medium removal, and also suitable for other mineral screening and classification.

Advantages

✔ Single or double deck design

✔ Reasonable vibration parameters avoid the natural frequencies of the sieve body and reduce the resonance effect

✔ The sidewalls are made of a single sheet and the frame (side walls and cross beams) is riveted with HUCK bolts,avoiding weaknesses or tensions in the metal that may be caused by welding, improving the strength and rigidity of the sidewalls and the reliability of the equipment

✔ Box beam construction is adopted on the girder of the exciter and the cross beam of the screen frame. The internal stiffeners enhance the rigidity and strength of the screen and lighten up the machine, so as to improve the efficiency and reduce the power consumption

✔ The girder of exciter and the cross beams are annealed after welding to eliminate the stress

✔ Machining between sections of girders and sidewalls

✔ Long lifetime ( screen body up to 10 years, drive up to more than 60,000 hours)

Key Data

Nominal length up to 11,000 mm

Nominal width up to 5,000 mm

Multiple deck multiple inclinations possible

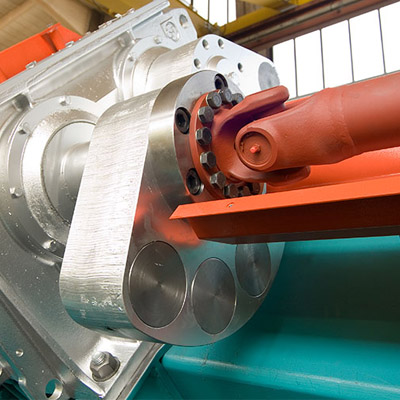

Drive VRV unbalanced motor or exciter

FAQ

Q1. How to choose the right equipment ?

A: VRV suggest you provide us the information of bulk material need to be handled, including the material parameters so that our technical staff will provide the most appropriate advice

Q2. Can I buy just one equipment?

A: Yes, there is no quantity limitation. We offer not only individual equipment, but also customize production lines for enterprises.

Q3. What’s your delivery time?

A: It depends on equipment. Normally it will take 1 to 3 months.

Q4. What’s your price terms and payment terms?

A: We accept EUR and USD

Q5. How to guarantee the quality?

A: VRV marks every equipment with unique serial number, by which design parameters can be easily traced and after-service can be ensured in years. VRV takes responsible for every equipment perpetually.

Any issues occurred during the life cycle of VRV vibratory equipment will be analyzed by our engineers thus to find out the optimal solution. Our company is also willing to assist customer’s field experts and maintenance engineers and provide our test data and advices to help them solve problems.