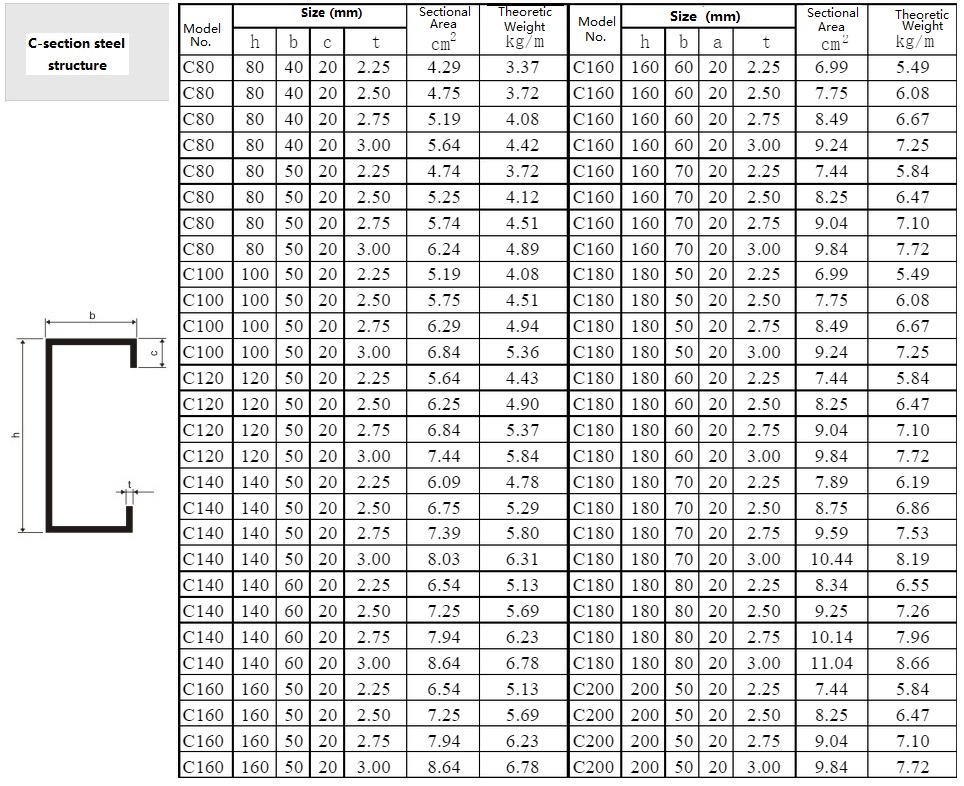

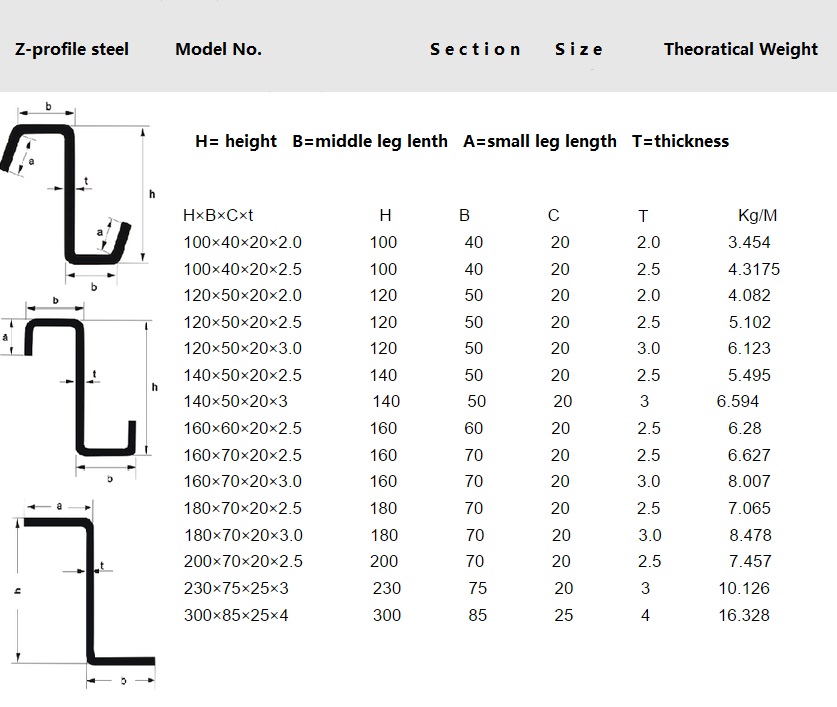

Profile drawings and theoretical weight for C-section steel and Z-section steel

Use of C chanel and Z channel

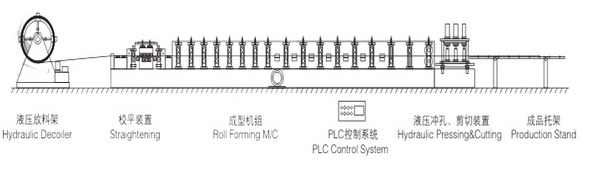

C profile and Z profile steel production flow chart

Decoiler -------feeding-------leveling------roll forming -------punching------cutting ---------output table

C channel steel /Z channel steel production line includes:

|

No.

|

Component name

|

Qty

|

|

1

|

De-coiler

|

1set

|

|

2

|

Forming machine

|

1set

|

|

3

|

Pressing Die

|

1set

|

|

4

|

Cutting system

|

1set

|

|

5

|

PLC controlling system

|

1set

|

|

6

|

Hydraulic pump station

|

1set

|

|

7

|

C section steel /Z section steel support table

|

1set

|

Machine technical parameters

1.De-coiler

We have two type De-coiler, one is manual type ,the other is Automatic De-coiler.

The function of the De-coiler is to put the raw material and rotate it to feed the machine.

|

Max width

|

500mm

|

|

Innder Dia

|

500-600mm

|

|

Outer Dia

|

1500mm

|

|

Max loading capacity

|

5000kg

|

Customer should tell us you need which type De-coiler and the max weight you will put.

2.Feeding part

The function is to guide and feed the raw material in a right direction

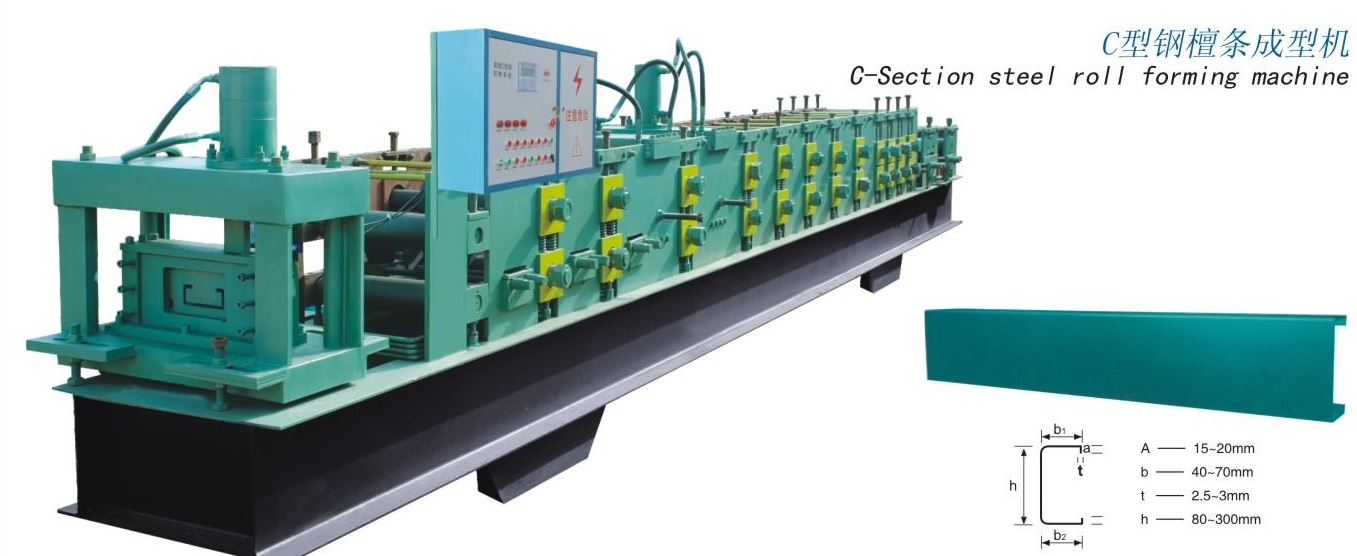

3.Roll forming part

The function is rolling and forming the steel .

|

Raw material thickness

|

1-3mm

|

|

Machine frame

|

400H steel welded

|

|

Frame panel thickness

|

20mm

|

|

Material of roller

|

GCr15 steel

|

|

Hardness of Heat Treatment

|

HRC58-60°

|

|

Diameter of shaft

|

80mm

|

|

Driven type

|

2"chain

|

|

Rollers

|

9 roller for leveling, 12 rollers for forming

|

|

Hydraulic station motor

|

4kw

|

|

Oil pump of Hydraulic station

|

Gear pump

|

|

Cutting method

|

Flying saw

|

|

Flying saw motor

|

11kw

|

|

Length precision

|

+/-2mm

|

|

Controlling

|

PLC

|

|

Main machine dimension

|

9800 x 1100 x1300mm

|

4.Cutting part

|

Material cut-off modular

|

Cr12steel

|

|

Hardness for Heat Treatment

|

HRC55-60

|

|

Cut-off type

|

Hydraulic ,automatic cut-off

|

|

Cut off modular

|

1set

|

5.PLC control system

PLC control system is used to control the machine which should cut the forming steel at the right length.

|

Type

|

PLC control system with touch screen

|

|

PLC brand

|

Japan Panasonic

|

|

Encoder

|

Omron

|

|

Length Error

|

+/-2mm

|

6.Support table for the finished goods

The function of this table is to support the finished goods.

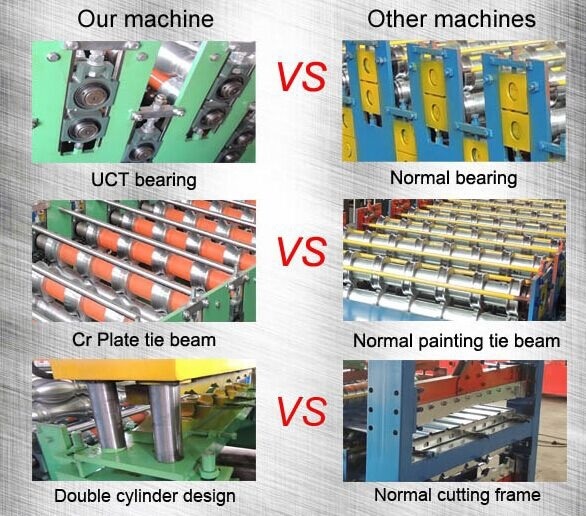

Our roll forming machine has which advantage?

Reference

Floor deck roll forming machine, please refer http://www.hbhscn.com/floor-deck-machine_p36.html

Glazed tile roll forming machine, please refer http://www.hbhscn.com/glaze-roof-tile-steel-roll-forming-machine_p37.html

Wall or roof panel roll forming machine, please refer http://www.hbhscn.com/wall-roof-panel-steel-roll-forming-machine_p40.html

Down pipe roll fomring machine, please refer http://www.hbhscn.com/down-pipe-roll-forming-machine_p42.html

EPS/color steel sandwich panel machine, please refer http://www.hbhscn.com/eps-color-steel-sandwich-panel-machine_p30.html

Video