YFL Ceramic O-port ball valves are suitable for corrosive fluid and abrasive solid duo to the excellent corrosion and abrasion resistance of ceramic. They are use widely in corrosive and abrasive applications as follow:

1. Copper powder, concentrated copper slurry, nickel slurry in Mining

2. Ash, lime slurry and gypsum slurry in flue gas desulphurisation (FGD) system in coal fired power plant

3. All types of dry bulk materials like quartz, fiber, ash glass and PP pellet in pneumatic conveying system

4. Limestone, ore, coke, dust, coal powder injection, carbon powder injection, additives like CaC, MgO2 in Iron & Steel

5. Dolomite, Ammonium nitrate slurry, Phosphoric acid with solids in Fertilizer industry

6. Aluminium oxide powder as catalyst, pigments( TiO2 suspension, Ti3Cl4, H2SO4+TiO2, FeCl2 etc.) in Petrochemical industry

7. Kaoflin, bentonite, fillers, dyes, pulp residue, lime suspension, MgO2, green liquor, wood particles in Paper industry

8. Silicon powder in Polysilicon industry

9. Alumina powder in Alumina plant

10. Cement in cement plant

For any other severe applications, please feel free to contact YFL engineers for best solutions.

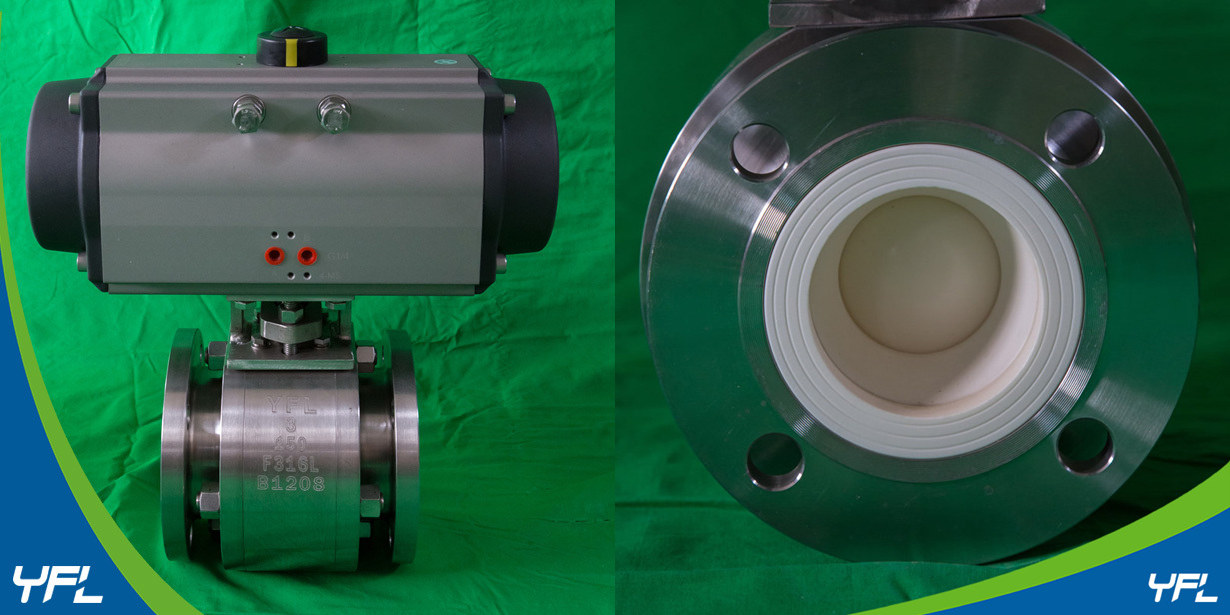

YFL Ceramic O-Port Ball Valves Features:

• All wet parts in material of ceramic

• Excellent abrasion and corrosion resistance

• Ceramic to ceramic seal makes sealing class VI

• Lower maintenance cost and less downtime loss

• Many times of service life than steel vavles

• Self-lubricated ceramic makes torque smaller

• Bare stem, Manual, Pneumatic, Electric on customer's request

Why Ceramic Valves?

1. Excellent wearresistance many times higher than steel duo to extremely high hardness

2. Extremely high corrosion resistance against almost all organic and inorganic solvents

3. Much longer working life, much less maintenance and shutdown loss

4. Stable, inert, no interact with, nor contamination to medium

Why Choose YFL?

1. Experienced in providing best solutions according to various sever working conditions to solve problems

2. Strict quality control from ceramic raw materials production, ceramic parts machining to pressure test and function test

3. Professional technical support and fast response trouble shooting

4. Approved & Registered vendor of Glencore & Umicore

5. Successful cases and reference list available

6. Customizable, Flexible, Short delivery time

Testimonials from Glencore in Mining industry

"We are very happy with the results so far, and the valves seem to be top quality.

You must understand that this factory has some of the world's toughest conditions with regards to abrasive and corrosive solutions. We dissolve metals and most products and suppliers we tested in our applications failed. "

YFL for 誉丰利 means benefiting from reputation.

We cast brand and forge reputation by quality and service.

We focus on your satisfaction and our responsibility.

Let‘s solve problems and create values for your projects.