JY Machinery Specializes In Automotive Products Prototyping

Experienced That Successfully Lead You from Prototype to Production

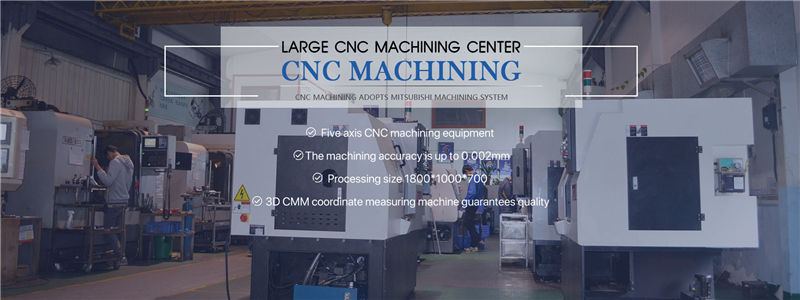

With more than 10 years of engineering and prototyping expertise, JY Machinery thrives in accelerating automotive product development with manufacturing on demand. We are committed to being your best full-service product development partner in the automotive industry. We focus on a variety of automotive prototyping and rapid manufacturing technologies, providing CNC machining, 3D printing, vacuum casting, injection molding, and sheet metal processing, which maintain a competitive edge with innovative service and highly skilled workforce. We’ll work together with you throughout every step of the automotive development and production process.

The custom automotive & motorcycle machining services that we can offer:

-

CNC milling

-

CNC turning

-

Multi-axis milling and turning

-

Automatic lathing

-

Custom Machine Parts

-

Injection mold

-

Metal Stamping parts

-

Welding& bending

-

Metal fabrication

-

Assembling service

Automotive Materials & Surface Treatments Available:

|

Material

|

Material type

|

Suface treatment

|

|

Aluminum or aluminum alloy

|

Aluminum6061,7075,5052,etc

|

Polishing, Plating Sandblasting, Laser engraving, mirror polish, Natural anodize, etc.

|

|

Steel

|

#45,Q235,Q345,etc

|

Polishing, Plating Sandblasting, Laser engraving, mirror polish, Zinc plating etc.

|

|

Stainless steel

|

SS303,SS304,etc

|

Polishing, Plating Sandblasting, Laser engraving, mirror polish, etc.

|

|

Plastic

|

POM, ABS, PE, HDPE, PVC, PP, acrylic, nylon, etc.

|

Polish, brush, mirror polish, etc.

|

|

Titainium

|

Gr2 titainium, Gr5 titainium, etc.

|

Polishing, Plating Sandblasting, Laser engraving, mirror polish, etc.

|

|

Brass

|

Brass, etc.

|

Polishing, Plating Sandblasting, Laser engraving, mirror polish, etc.

|

|

Copper

|

Copper, etc.

|

Polishing, Plating Sandblasting, Laser engraving, mirror polish, etc.

|

|

Bronze

|

Bronze, etc.

|

Polish, brush, mirror polish, etc.

|

|

Composite

|

FR4,G10,G11,GPO-3,Phenolic Cotton / Paper Laminated

|

--

|

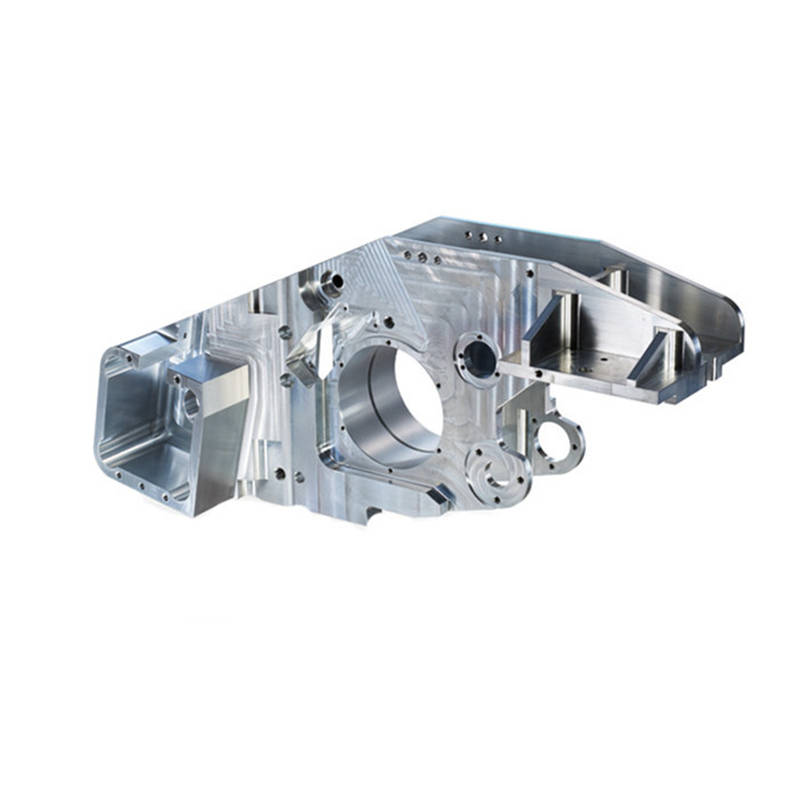

Note:The products shown here is only to present the scope of our business activities. We can manufacture custom parts according to your drawings or samples.

What you will get from our here?

* Competitive Price Of CNC Precision Machinery part

* Good Quality Assurance

* In Time Sampling & In Time Shipment

* Quality Guarantee

* Free Sample Can Be Provided Some Time

* Low MOQ

* Reply in 24 hours and fast quotaion

*Small MOQ acceptable

Contact us:

We make CNC parts according to customers' artwork, if you have any parts need to be made, please kindly send 2D and 3D artwork to us. And Please kindly mark dimension, tolerance, material, surface or hot treatment on 2D artwork, then we will according to it to calculate cost for you.

2D artwork format:JPG, PDF, DWG.

3D artwork format: IGS,STP,STEP.

FAQ:

Q:Can you CNC aluminum?

A:JY Machinery is a CNC processing production enterprise. From structural design to production, one-stop service, from expected to shipment, strictly in accordance with ISO2015 quality management system, to ensure delivery on time, quality, and quantity, using 3D measurement, assembly success rate 99.8%, with an accuracy of 0.005mm.

Q:What is the hardest grade of aluminum?

A:7000 series aluminum alloy: mainly contains zinc copy element.It also belongs to aviation series, which is aluminum, magnesium, zinc and copper alloy, which can be heat treated, and belongs to super dura aluminum alloy, which has good wear resistance.CNC 7075 aluminum plate is stress-relieved, and will not be deformed or warped after processing, with high thermal conductivity.Can shorten the molding time, improve work efficiency.

Q:What does the T stand for in aluminum?

A:H: working hardening state, suitable for 1 series, 3 series, 5 series and other non-heat-treated aluminum alloy;T: the stable state of the product after heat treatment, suitable for heat treatment of 2 series, 6 series, 7 series aluminum alloy;F: the original state after processing, applicable to the processing product in the molding process is unable to learn the performance requirements;O: annealed state with one Arabic digit other than 0 after affixing.

Q:Can you anodize 7075 aluminum?

A:7075 aluminum is often used in aviation parts, molds, fixtures, mechanical parts and other fields.There are many applications that require anodic oxidation of aluminum alloy materials, but the anodic oxidation effect of 7075 aluminum alloy materials is not stable, and generally only black or natural anodic oxidation processing can be done.