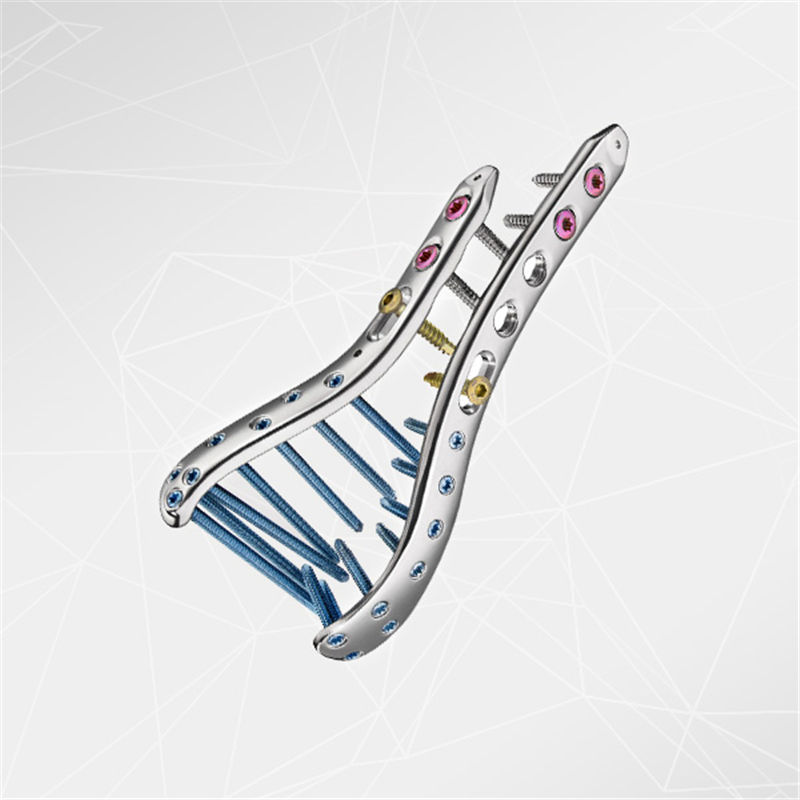

Product Description:

Product Name: CNC Machining Medical Titanium Orthopedic Implants

Machined Technology: CNC Machining

Material: Titanium

Surface Treatment: Polish

Precision Tolerance: ±0.01mm

Production Qty: CNC Prototyping to Mass Production

Place of Origin: Xiamen,China

Industry: CNC Machining Medical implants

Color:Customized

Delivery Time(Prototype):3-5 workd days

FAQ:

Q:What is CNC Machining?

A:CNC machining is a production process in which pre-programmed computer system software dictates the activity of manufacturing facility devices and also equipment. The process can be made use of to manage a series of complex equipment, from mills as well as turrets to mills and also routers. With CNC machining, three-dimensional reducing tasks can be accomplished in a solitary collection of triggers.

When a CNC system is turned on, the wanted cuts are set right into the software application and also dictated to matching devices and also equipment, which execute the dimensional tasks as specified, similar to a robotic.

Q:How many types of CNC machines are there?

A:There are primarily five different kinds of CNC machines:

Plasma Cutting Machine

Laser Cutting Machine.

Milling Machine.

Router Machine.

CNC Lathe Machine.

Q:What kind of a finish does CNC machining leave?

A:As a result of the spinning activity created by the CNC milling maker's cutter, the surface treatment of CNC machined components will certainly have noticeable toolmarks. If you call for a smooth, unblemished surface to your component, we suggest picking an additional coating: grained coating (can just be related to the beyond machined rooms because of geometry) or powdercoat.

Q:Which industries benefit from CNC machining?

A:Numerous markets profit from CNC machining, though they are even more necessary in some areas than others. Various CNC machines are capable of different degrees of detail during production.CNC machined parts from JY Machinery are made to be as accuracy as feasible.

Q:What is CNC milling?

A:CNC milling develops components by cutting down material along the axis of the piece. The CNC milling equipments used by tools are able to work along 5-axex, offering you greater control over your component.

Products Show: