Compact Spin Coater 3 Vacuum Chucks & Vacuum Pump

VTC-100A is a compact spin coater with vacuum chucks designed for easy and quick coating via sol-gel for wafers up to 4".

The spinning speed is variable from 500-8000 rpm with two programmable segments.

The package comes included with complete accessories for immediate use

|

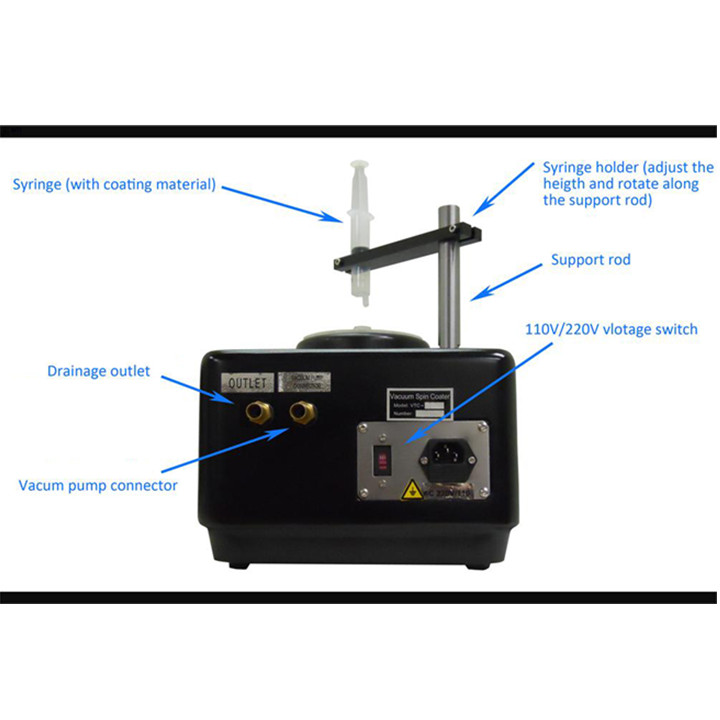

Structure

|

Aluminum casting case to keep spinning stable

Liquid disk made to resist most of the corrosive solutions

Drainage outlet and vacuum pump connector are on back panel

One filter is included in standard package. It is used to connect thecoater

for preventing waste water flowing into the pump

One oil-less vacuum pump is included in the standard package

|

|

Chamber & Vacuum Chuck

|

Chamber Diameter: 145 mm

3 sets of PP anti-corrosive vacuum chucks with chuck o-ring come in

different sizes (1'', 2'' and 4'')

1 piece of adhesive tape (6'' W x 24'' L) is included for coating

irregularly shaped substrates (e.g. Place the irregular substrate on the adhesive

tape,then the vacuum chuck will hold the tape by suction)

Mini suction cups are available for the small wafer with less 1" Dia.

or substrate with regular ( 5x5, or 10x10mm) or irregular shape.

|

|

Vacuum Pump

|

Vacuum grade rubber pipe is included for immediate use

|

|

Spin Speed & Time

|

Digital control panel with TWO programmable segments for different

spin times and speeds.

Spinning speed: 500 - 8000 RPM

Spinnning Time: 1 - 60s

|

|

Liquid Injecting

|

20mL syringe is used to contain the coating material

The syringe holder height can be adjusted and rotated freely along the

support rod

|

|

Input Power

|

220VAC please select the voltage in options bar (10A fuse)

|

|

Motor Power

|

24V DC motor with 150W Max.

|

|

Product Dimensions

|

13''(L) x 10''(W) x 8.5''(H)

|

|

Net Weight

|

15 kg (33 lbs)

|

|

Compliance

|

CE Certified

|

|

Warranty

|

One year limited with lifetime support

Rusting and damage due to improper storage condition or maintenance are not

covered by warranty

|

|

Shipping Weight

|

46 kg (100 lbs)

|

|

Application Notes

|

In order to achieve optimal coating quality, please consider cleaning

substrates by a plasma cleaner prior to coating.

This will significantly reduce the surface tension on the substrates.

Cleaning instruction for the spin coaters.

Strongly suggest you put the coater under a fume hood as below right

When using the coater in glovebox with Ar gas, vacuum pump must

put in outside the glovebox via vacuum feedthrough or adaptor

|

|

Warnings

|

Do not overflush the water bowl/base with any kinds of liquid.

Excess liquid will leak into the motor shaft and cause damage.

Please use fabric cloth to wipe out the residues remain in the bow/base.

If necessary, turn on the water outlet when flushing the water bowl/baseto

avoid liquid overflowing during the operation.

|

|

Shipping Dimensions

|

40"(L) x 28"(W) x 24"(H)

|

|

Shipping Weight

|

46 kg (100 lbs)

|