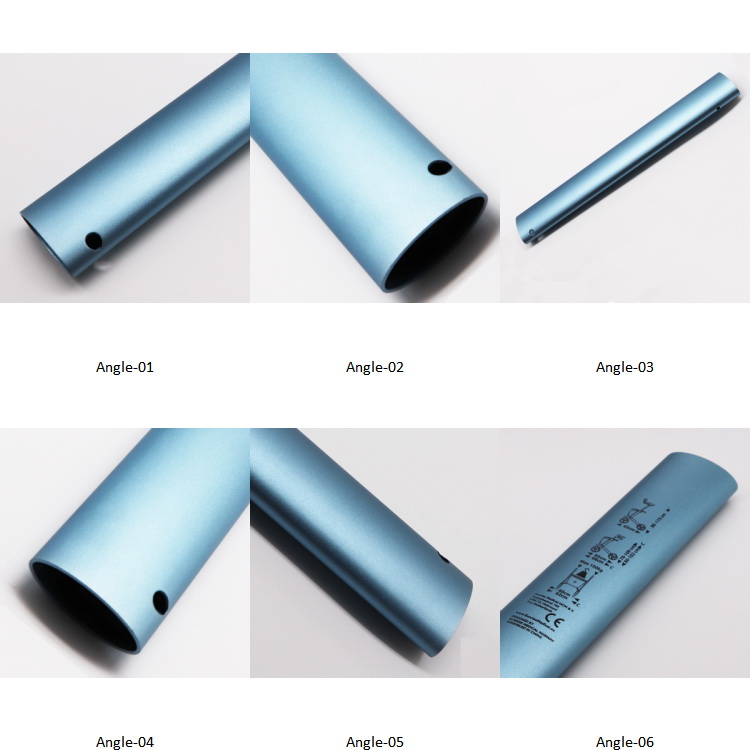

Composite aluminum extrusion parts bicycle accessories

Product Description:

|

Product Name

|

Composite aluminum extrusion parts bicycle accessories

|

|

Certification

|

ISO9001

|

|

Material

|

aluminum alloy

|

|

Thickness

|

General profiles thickness: 0.8 - 5.0 mm

Anodized protection thickness: 8 - 25 um

Powder coating color thickness: 40 - 120 um

|

|

Length

|

3m~6m or more per piece. Customized request available

|

|

Shape

|

Square, Rectangle, Round, Flat, Angle, T profile etc

Or as per customer's requirement

|

|

Surface Treatment

|

Mill, anodized, powder coated, electrophoresis, wood grain, timber, PVDF paint, polish, brushed. As clients require

|

|

Color

|

Red,black,blue,white,green,Orange,Silver,customized

|

|

Application

|

Windows and doors, curtain walls, glass wall, furniture, ceiling, kitchen, LED strip, transportation rail, vehicles, motor housing, machine, tent, solar. Industrial profile, Decoration profile etc

|

|

Deep Process

|

CNC, drilling, milling, cutting, welding, bending, assembling

|

|

OEM service

|

Available for aluminum profiles

|

|

Characteristics

|

Strong, stylish, durable, corrosion-resistant

|

|

Packing Details

|

Inside: packed with plastic film to protect each piece

Outside: Wrap to be bundles by waterproof craft paper or EPE film

Customized as customers request is available

|

|

Delivery

|

25-30 working days after payment of aluminum profiles

|

Feature of aluminum profile tube

1. In the extrusion process, the extruded metal can obtain a stronger and uniform triaxial compression stress state than rolling forging in the deformation zone, which can give full play to the plasticity of the machined metal itselft

2.Extrusion molding flexibility, only need to replace die and other extrusion tools, can be produced on a equipment with different shapes, specifications and varieties of products, the operation of replacing extrusion die is simple and fast, time-saving and efficient

3. The process is short, the production is convenient, the whole structure with larger area than hot die forging or forming rolling can be obtained by one extrusion, the investment of equipment is less, the cost of die is low, and the economic benefit is high.

Company profile

FAQ

Q: What is the minimum order quantity?

A: The minimum order quantity is one piece/set. IF you need more quantity and the price is cheaper.

Q: Can you mass produce?

A: Yes, we are a factory that can provide precision CNC machining, rapid prototyping, injection molding and injection molding services. After both parties confirm the sample, we can start mass production. We are very convenient for our customers to choose us as a -stop solution provider.

Q: What 3D drawing files should the machine use?

A: CNC machines can only read * IGS, * STP, * STEP, * IGES, * X-T format, for * STL format, it is equipped with a 3d printer and SLA.

Q: If you don't visit your company, can you understand how my product is developing?

A: We will provide detailed production planning, inspection process records and weekly reports with digital images and videos.

Show processing progress.