FAQ

Q: What is copper?

A:Copper,

also known as red copper, is a simple substance of copper. It is named for its

purple-red color. See copper for various properties. Red copper is industrial

pure copper, with a melting point of 1083 ° C, no isomeric transformation, and

a relative density of 8.9, which is five times that of magnesium. The mass of

the same volume is about 15% heavier than ordinary steel. Red copper is

generally called red copper because it has a rose-red color and is purple when

an oxide film is formed on the surface. It is copper containing a certain

amount of oxygen, so it is also called oxygen-containing copper.

Q:What‘s the performance of copper?

A:Copper is

a kind of relatively pure copper. It can be generally regarded as pure copper.

It has good conductivity and plasticity, but its strength and hardness are

poor. Red copper has excellent thermal conductivity, ductility and corrosion

resistance. Trace impurities in red copper have a serious impact on the

electrical and thermal conductivity of copper. Among them, titanium,

phosphorus, iron, silicon, etc. significantly reduce the conductivity, while

cadmium, zinc, etc. have little effect. The solid solubility of sulfur,

selenium, tellurium, etc. in copper is very small, and can form brittle

compounds with copper, which has little effect on conductivity, but can reduce

processing plasticity.

Copper has good corrosion resistance in the

atmosphere, sea water and certain non-oxidizing acids (hydrochloric acid,

dilute sulfuric acid), alkalis, salt solutions and various organic acids

(acetic acid, citric acid), and is used in the chemical industry. In addition,

copper has good weldability, and can be made into various semi-finished

products and finished products by cold and thermoplastic processing.

Q:What

is Copper CNC Machining?

A:According

to the customer's drawings, a set of processing programs is prepared by the

computer, and the copper is used as the raw material to process the items

digitally, including cutting, drilling, tapping, etc., which basically rely on CNC

operations.

Q:What‘s the advantages for Copper CNC Machining?

A: 1. Significantly

reduce the number of tooling, processing complex shape parts does not require

complex tooling

2. The production efficiency is higher in

the case of multiple varieties and small batch production, which can reduce the

time for production preparation, machine tool adjustment and process

inspection, and the cutting time is reduced due to the use of the optimal

cutting amount.

3. It can process complex profiles that are

difficult to process with conventional methods, and can even process some

unobservable parts.

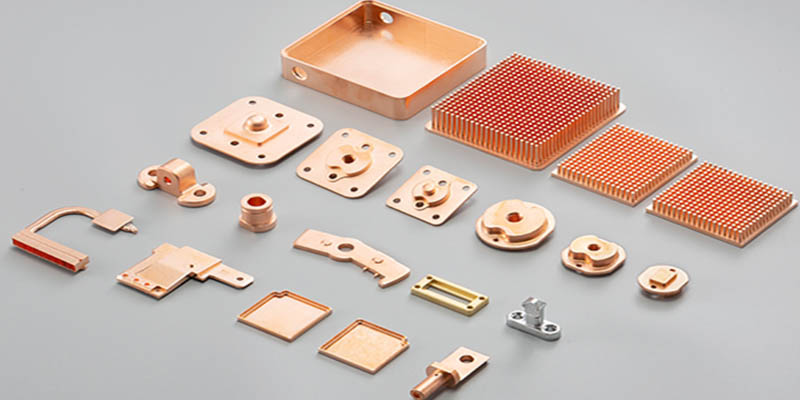

Product Show

Workshop

Testing Equipment

Packaging & Shipping