Custom High Temperature Resistant Silicone Gasket

Silicone gasket is a sealing device made from silicone rubber material that is used to create a tight and reliable seal between two or more surfaces. Silicone gaskets are designed to withstand a wide range of temperatures, chemicals, and environmental conditions, making them suitable for various applications across different industries.

Material: Silicone gaskets are typically made from high-quality silicone rubber. Silicone rubber is a synthetic elastomer known for its excellent physical properties, including flexibility, durability, and resilience. It is resistant to extreme temperatures, chemicals, UV radiation, moisture, and weathering, making it ideal for sealing applications.

Specification

| Material |

100% silicone |

|

Brand Name

|

JE |

| Processing Service |

Moulding,Cutting

|

| Temperature resistance |

-40~250 ºC |

| Hardness |

10-45C |

|

Color

|

custom |

| Size |

custom |

| Product Certification |

FDA,ROHS,ISO,REACH,MSDS |

| Packing |

Based on the order

|

| Applications |

Seals for aircrafts/CO2/FOOD/Engine

|

MATERIAL PROPERTIES

| MATERIAL |

TEMP. RANGE |

ADVANTAGE |

FULL NAME |

| Silicone (MQ/MVQ/MPQ) |

-40〜200℃ |

Excellent heat resistance;

Good compression set resistance;

Good ozone resistance;

Food grade compliant Medical grade compliant

|

Silicone rubber Silicon |

| EPDM |

-40〜150℃ |

Excellent water resistance;

Good weather resistance;

Good ozone resistance;

Good chemical resistance;

|

Ethylene-Propylene -Diene Terpolymer Ethylene-Propylene -Diene Monomer |

| NBR |

-40〜120℃ |

Excellent oil resistance;

Good water resistance;

Good solvent resistance;

Good air tightness;

Good compression set resistance;

Good wear resistance

|

Acrylonitrilebutadiene rubber Nitrile -butadiene Rubber Buna-N rubber |

| NR |

-40〜90℃ |

Good wear resistance;

Good elasticity;

Good tensile strength;

Good elongation

|

Natural rubber |

| SBR |

-30〜100℃ |

Good water resistance;

Good wear resistance;

Good weather resistance;

Good elasticity

|

Styrene-butadiene rubber |

| FKM/FPM |

-20〜200℃ |

Excellent heat resistance;

Excellent oil resistance;

Excellent chemical resistance;

|

Fluorocarbon |

Features

Design and Construction: Silicone gaskets come in various shapes, sizes, and configurations to suit different sealing requirements. They can be manufactured as flat gaskets, O-rings, flange gaskets, custom-molded gaskets, or extruded profiles. The design and construction of the gasket depend on the specific application and the type of sealing needed.

Sealing Function: The primary purpose of a silicone gasket is to create a secure and leak-proof seal between two mating surfaces. The gasket fills the irregularities and gaps between the surfaces, preventing the escape or ingress of fluids, gases, dust, or other contaminants. This sealing function helps maintain pressure integrity, prevent leakage, and protect the components or systems being sealed.

Temperature Resistance: Silicone gaskets exhibit excellent temperature resistance properties. They can withstand both high and low temperature extremes without losing their physical properties or compromising the seal. Silicone gaskets can withstand temperatures ranging from sub-zero temperatures up to several hundred degrees Celsius, depending on the specific formulation and grade of silicone rubber used.

Chemical Resistance: Silicone gaskets offer good resistance to a wide range of chemicals, including acids, bases, solvents, oils, and many other substances. This chemical resistance ensures that the gaskets maintain their integrity and sealing properties even when exposed to aggressive or corrosive environments. However, it is important to consider the compatibility of the specific silicone grade with the intended chemicals to ensure optimal performance.

Compression and Flexibility: Silicone gaskets are known for their excellent compression and flexibility characteristics. They can be compressed and deformed to fill gaps and conform to irregular surfaces, ensuring a tight and effective seal. The flexibility of silicone gaskets allows them to adapt to changes in temperature, pressure, or movement without losing their sealing capabilities.

Applications

Silicone gaskets find applications in a wide range of industries, including automotive, aerospace, electronics, medical, food and beverage, HVAC (Heating, Ventilation, and Air Conditioning), and many others. They are used in engines, pumps, valves, electrical enclosures, pipe connections, sealing lids or covers, and various other equipment or systems that require reliable sealing.

Product Images

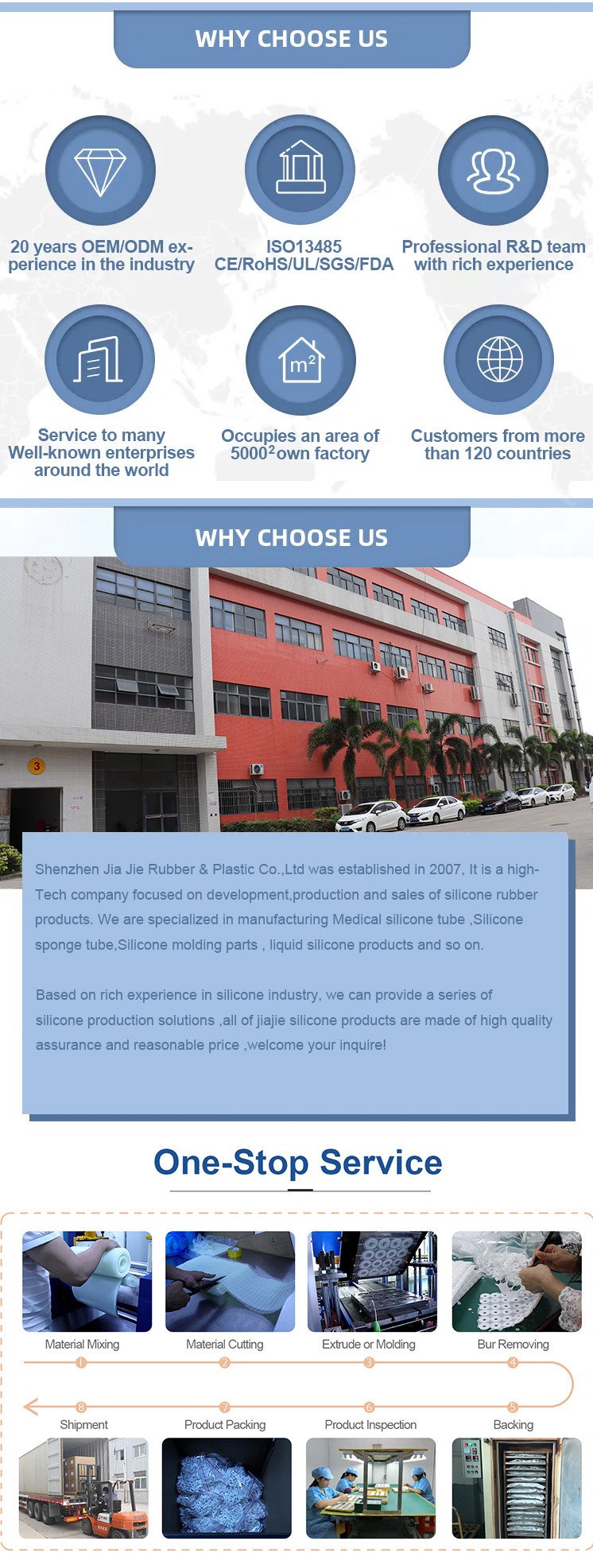

Our Factory