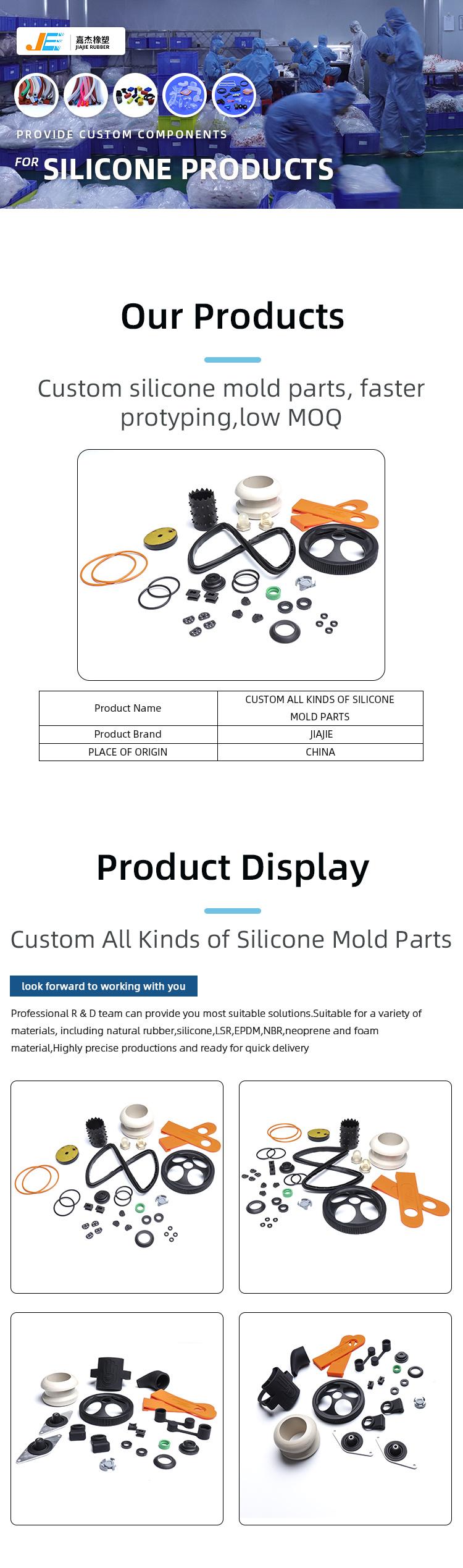

Custom-made silicone rubber molded parts applications

Seals and gaskets: These parts are commonly used in food processing and packaging equipment to prevent leakage and contamination.

O-rings: O-rings made of food grade silicone rubber are used in food and beverage processing and packaging equipment to provide a seal and prevent contamination.

Hoses and tubing: Food grade silicone rubber is also used to manufacture hoses and tubing for food and beverage transfer applications. The flexible and non-toxic nature of silicone makes it ideal for these applications.

Bakeware: Silicone bakeware such as muffin cups, baking mats, and cake pans are made from food grade silicone rubber, providing a non-stick surface that is easy to clean and safe for food contact.

Specification

| Material |

100% silicone |

|

Brand Name

|

JE |

| Processing Service |

Moulding,Cutting

|

| Temperature resistance |

-40~250 ºC |

| Hardness |

30-80A |

|

Color

|

custom |

| Size |

custom |

| Product Certification |

FDA,ROHS,ISO,REACH,MSDS |

| Packing |

Based on the order

|

| Applications |

Seals for aircrafts/CO2/FOOD/Engine

|

MATERIAL PROPERTIES

| MATERIAL |

TEMP. RANGE |

ADVANTAGE |

FULL NAME |

| Silicone (MQ/MVQ/MPQ) |

-40〜200℃ |

Excellent heat resistance;

Good compression set resistance;

Good ozone resistance;

Food grade compliant Medical grade compliant

|

Silicone rubber Silicon |

| EPDM |

-40〜150℃ |

Excellent water resistance;

Good weather resistance;

Good ozone resistance;

Good chemical resistance;

|

Ethylene-Propylene -Diene Terpolymer Ethylene-Propylene -Diene Monomer |

| NBR |

-40〜120℃ |

Excellent oil resistance;

Good water resistance;

Good solvent resistance;

Good air tightness;

Good compression set resistance;

Good wear resistance

|

Acrylonitrilebutadiene rubber Nitrile -butadiene Rubber Buna-N rubber |

| NR |

-40〜90℃ |

Good wear resistance;

Good elasticity;

Good tensile strength;

Good elongation

|

Natural rubber |

| SBR |

-30〜100℃ |

Good water resistance;

Good wear resistance;

Good weather resistance;

Good elasticity

|

Styrene-butadiene rubber |

| FKM/FPM |

-20〜200℃ |

Excellent heat resistance;

Excellent oil resistance;

Excellent chemical resistance;

|

Fluorocarbon |

Features

- Customization: Silicone rubber molded parts can be designed and manufactured to meet specific requirements and specifications. This allows for precise customization, ensuring the part fits the intended application perfectly.

- Flexibility and Elasticity: Silicone rubber is known for its excellent flexibility and elasticity. Molded parts can be bent, stretched, or compressed without losing their original shape, making them ideal for applications that require repeated movement or deformation.

- Heat Resistance: Silicone rubber has high-temperature resistance, typically able to withstand temperatures ranging from -50°C to 200°C (-58°F to 392°F). This property makes it suitable for applications where exposure to extreme heat is expected.

- Chemical Resistance: Silicone rubber exhibits excellent resistance to a wide range of chemicals, including acids, alkalis, oils, and solvents. This makes it well-suited for applications that involve contact with various substances.

- Electrical Insulation: Silicone rubber is an excellent electrical insulator, making it suitable for electrical and electronic applications. It can resist high voltage and prevent electrical leakage, providing safety and reliability.

- Weather Resistance: Silicone rubber molded parts have excellent resistance to UV radiation, ozone, and weathering. They can withstand outdoor conditions without deteriorating or losing their properties, making them ideal for outdoor applications.

- Compression Set Resistance: Silicone rubber displays low compression set, meaning it can maintain its original shape and properties even after being compressed for extended periods. This is advantageous for applications where the part needs to maintain its functionality and shape under constant pressure.

- Biocompatibility: Silicone rubber is biocompatible and widely used in medical and healthcare applications. It is hypoallergenic, non-toxic, and does not cause adverse reactions when in contact with the human body, making it suitable for medical devices and implants.

- Easy Release: Silicone rubber molds offer excellent release properties, allowing for easy demolding of the final parts. This facilitates the production process and helps achieve accurate replication of complex shapes and details.

- Durability: Silicone rubber molded parts are known for their durability and longevity. They can withstand harsh environments, repeated use, and wear without significant degradation, ensuring a long service life.

Product Images

Our Factory