|

Item No

|

Bilzzard

Cararra SQ6174

|

|

Color

|

White

|

|

Size

|

3000 X 1400mm,

3000 X 1600mm, 3200 X 1600mm, 3200 x 1650mm, etc.

|

|

Thickness

|

15mm, 18mm,

20mm, 30mm.

|

|

Thickness Tolerance

|

+/-1mm for Slab, +/-0.5mm for Tile

|

|

Quartz content

|

>93%

|

|

Flexural Strength

|

25~35Mpa

|

|

Quality control

|

Color difference

control,Safe packing,

Thickness

tolerance: /-1mm

All products are

checked by experienced QC piece by piece and then pack

|

|

Package

|

Packed with

strong wooden crates and foam, film inside.

|

|

Sample Request

|

Free Sample with

Freight Paid by Customer.

|

|

Payment terms

|

T/T, L/C,

Western Union, Paypal

|

With a variety of on-trend colors and

styles to choose from, you’ll find exactly what you need non matter the style

of your kitchen, bathroom, or outdoor area. Quartz offers a wide selection that includes whites, black and grays, red,yellow,pink,etc.

And some that mimic granite and marble.Because it can mimic the look of natural

stone and can be customized, engineered stone is available in a wider range of

colors.

Unlike other natural stones, quartz is

require low maintenance after it has been installed. Granite and marble will

need to be sealed annually at least, but quartz will never need anything other

than regular cleaning, as you would do anyway. s quartz countertops are

non-porous, it also makes them easier to clean and fend off bacteria. Another

advantage of quartz is that the environmental impact is low. The supply of

quartz is abundant, and the finished product is non-toxic, non-allergenic, and

durable.

Quartz has a higher hardness rating as

compared to natural stone such as granite and marble. Its impressive scratch

resistant qualities make it difficult to crack or chip. This makes it a

fantastic choice for kitchen countertops and bathroom vanity top, in particular.

Appication:

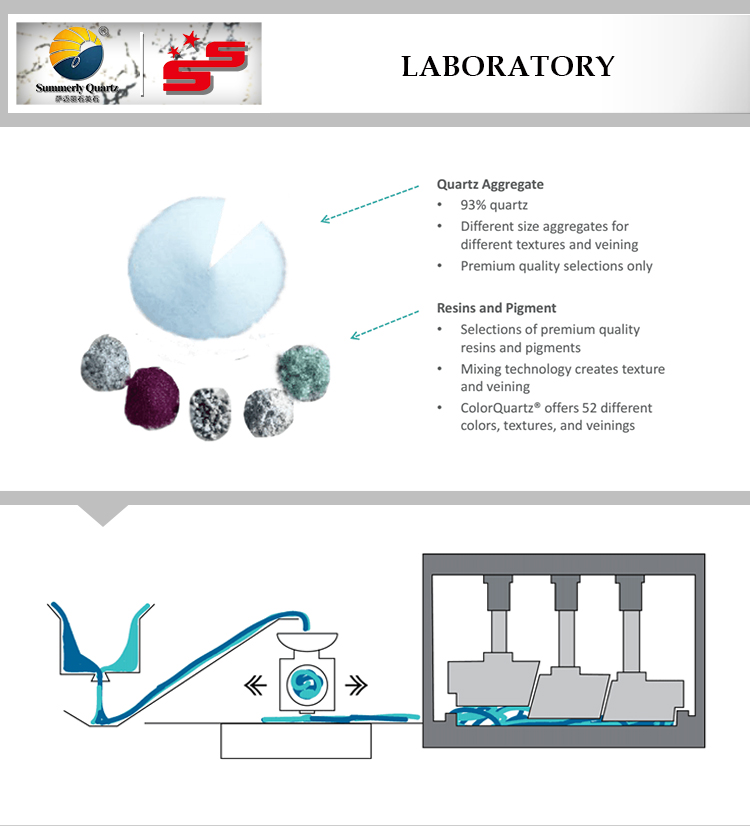

Production Engineering:

1. The process begin with a rigorous

inspection of raw materials.

2. Feeding natural quartz raw material and

polymer resins and inorganic pigments in to mixers and blending them together.

3. After stirring the mixture, then pouring

them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a

special vacuum and vibration process at pressure machine.

5. The slab then moved to the curing kiln and

heated for a period time which give them ultimate strength and solidity.

6. Trimming edges, leveling , thicknessing

and polishing surface to perfect finished.

7.Finally, the quartz stone slabs passed

through quality inspection and packed with a plastic film.

Packing wooden

crate (slab) wooden box (tiles/

countertop)

Sample Room:

Lboratory: