Custom Silicone Molded Components in Various Shapes

Our collection showcases a remarkable array of Custom Silicone Molded Components in an assortment of captivating shapes. With meticulous attention to detail, we specialize in curating silicone solutions that align seamlessly with your distinct requirements. Our cutting-edge molding techniques ensure impeccable precision, while our unwavering dedication to excellence assures products of exceptional performance and longevity. From intricate designs that captivate the eye to utilitarian shapes that serve with utmost functionality, we are committed to realizing your creative aspirations. Explore the limitless possibilities of silicone through our unparalleled custom molding services.

Whether you need intricate silicone parts for industrial applications or creative silicone components for consumer products, we're here to meet your customization needs. With a commitment to quality and innovation, we ensure that each piece is meticulously crafted to your specifications. Experience the perfect blend of functionality and aesthetics with our custom silicone molded components in various shapes.

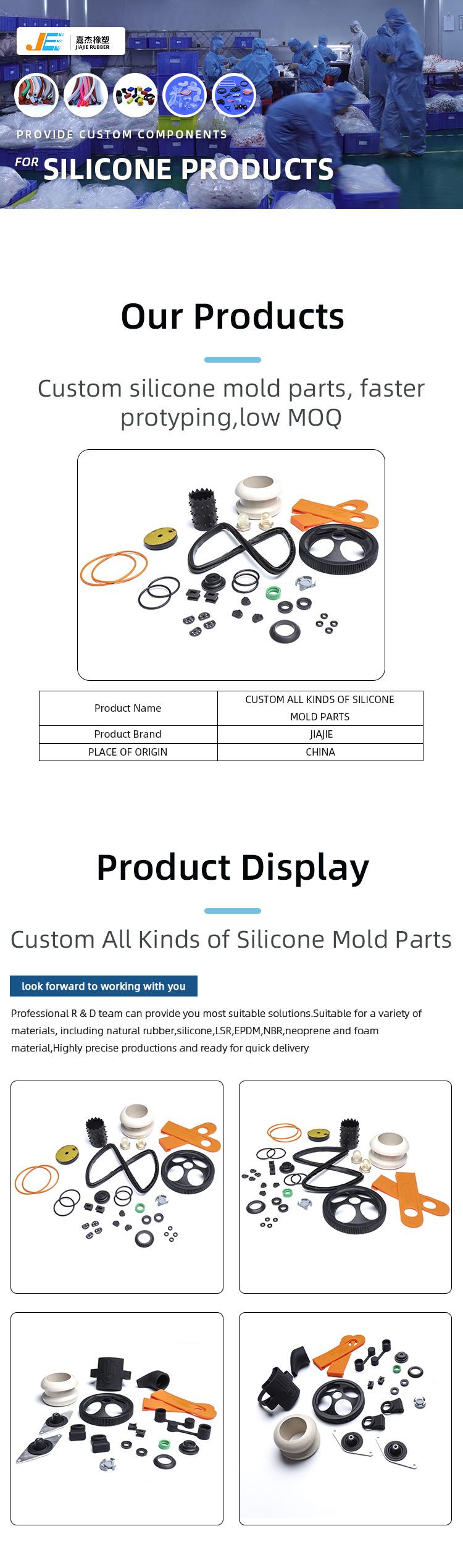

Specification

| Material |

100% silicone |

|

Brand Name

|

JE |

| Processing Service |

Moulding,Cutting

|

| Temperature resistance |

-40~250 ºC |

| Hardness |

30-80A |

|

Color

|

custom |

| Size |

custom |

| Product Certification |

FDA,ROHS,ISO,REACH,MSDS |

| Packing |

Based on the order

|

| Applications |

Seals for aircrafts/CO2/FOOD/Engine

|

MATERIAL PROPERTIES

| MATERIAL |

TEMP. RANGE |

ADVANTAGE |

FULL NAME |

| Silicone (MQ/MVQ/MPQ) |

-40〜200℃ |

Excellent heat resistance;

Good compression set resistance;

Good ozone resistance;

Food grade compliant Medical grade compliant

|

Silicone rubber Silicon |

| EPDM |

-40〜150℃ |

Excellent water resistance;

Good weather resistance;

Good ozone resistance;

Good chemical resistance;

|

Ethylene-Propylene -Diene Terpolymer Ethylene-Propylene -Diene Monomer |

| NBR |

-40〜120℃ |

Excellent oil resistance;

Good water resistance;

Good solvent resistance;

Good air tightness;

Good compression set resistance;

Good wear resistance

|

Acrylonitrilebutadiene rubber Nitrile -butadiene Rubber Buna-N rubber |

| NR |

-40〜90℃ |

Good wear resistance;

Good elasticity;

Good tensile strength;

Good elongation

|

Natural rubber |

| SBR |

-30〜100℃ |

Good water resistance;

Good wear resistance;

Good weather resistance;

Good elasticity

|

Styrene-butadiene rubber |

| FKM/FPM |

-20〜200℃ |

Excellent heat resistance;

Excellent oil resistance;

Excellent chemical resistance;

|

Fluorocarbon |

Features

- Premium Silicone Material: We use high-quality silicone that offers exceptional durability, flexibility, and resistance to varying environmental conditions.

- Customizable Options: Choose from a range of colors, finishes, and additional features to tailor the components to your brand or project requirements.

- Tailored Precision: Each component is meticulously crafted to match your exact specifications, ensuring a seamless fit and function.

- Versatile Design: Our wide range of available shapes allows you to bring your unique ideas to life, from intricate forms to practical geometries.

- Premium Silicone Material: We use high-quality silicone that offers exceptional durability, flexibility, and resistance to varying environmental conditions.

- Superior Performance: These components are designed to excel in their intended applications, offering reliability and longevity even in demanding situations.

- Seamless Integration: Whether for aesthetic purposes or functional needs, our components seamlessly integrate into your existing systems or designs.

- Precision Molding: Our advanced molding technology guarantees consistent accuracy, ensuring that each component adheres to the highest standards.

- Quality Assurance: Rigorous quality control processes are in place to guarantee that every component leaving our facility meets stringent quality benchmarks.

- Expertise and Experience: With years of experience in silicone molding, our team possesses the knowledge to offer guidance and solutions to even the most intricate design challenges.

- Endless Possibilities: From consumer products to industrial applications, our custom molded components offer endless possibilities for innovation and creativity.

Product Images

Our Factory