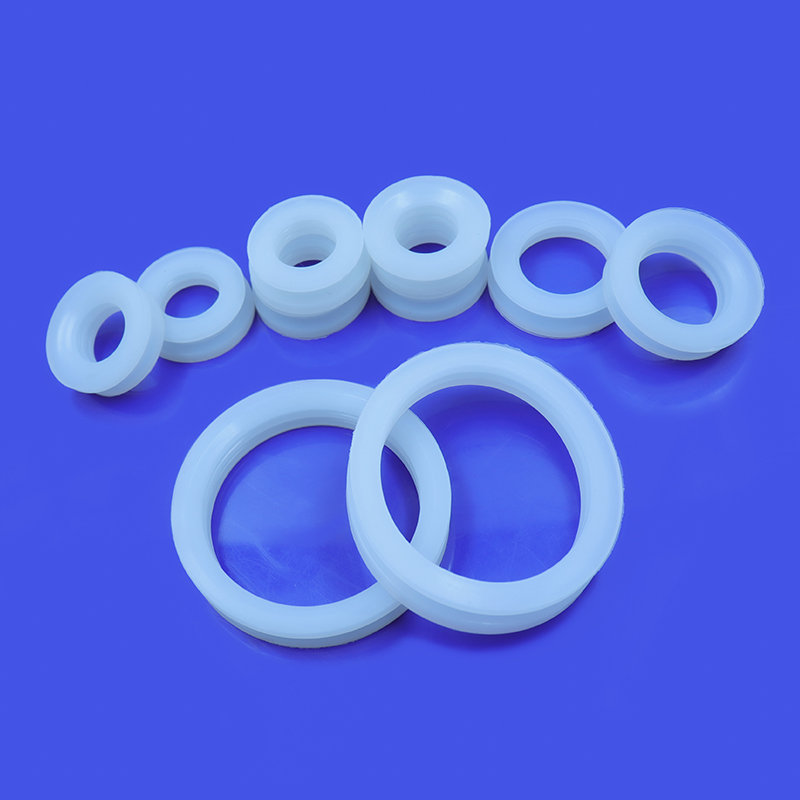

Custom Waterproof silicone rings Injection-molded silicone rings

Molded silicone rings are flexible, durable rings made of silicone material that can be molded into various shapes and sizes. These rings are popular for their versatility, as they can be used for a wide range of applications, such as jewelry, sports, medical, and industrial uses.

One of the key advantages of molded silicone rings is their resistance to water and chemicals, making them ideal for use in wet or harsh environments. They are also non-conductive, non-toxic, and hypoallergenic, which makes them suitable for people with sensitive skin.

Molded silicone rings come in a variety of colors and designs, and they are often used as an alternative to traditional metal rings. They are lightweight and comfortable to wear, making them a popular choice for people who want a ring that is both stylish and functional.

Overall, molded silicone rings are a versatile and practical choice for a wide range of applications, from fashion accessories to industrial tools.

Specification

| Material |

100% silicone |

|

Brand Name

|

JE |

| Processing Service |

Moulding,Cutting

|

| Temperature resistance |

-40~250 ºC |

| Hardness |

10-45C |

|

Color

|

custom |

| Size |

custom |

| Product Certification |

FDA,ROHS,ISO,REACH,MSDS |

| Packing |

Based on the order

|

| Applications |

Seals for aircrafts/CO2/FOOD/Engine

|

MATERIAL PROPERTIES

| MATERIAL |

TEMP. RANGE |

ADVANTAGE |

FULL NAME |

| Silicone (MQ/MVQ/MPQ) |

-40〜200℃ |

Excellent heat resistance;

Good compression set resistance;

Good ozone resistance;

Food grade compliant Medical grade compliant

|

Silicone rubber Silicon |

| EPDM |

-40〜150℃ |

Excellent water resistance;

Good weather resistance;

Good ozone resistance;

Good chemical resistance;

|

Ethylene-Propylene -Diene Terpolymer Ethylene-Propylene -Diene Monomer |

| NBR |

-40〜120℃ |

Excellent oil resistance;

Good water resistance;

Good solvent resistance;

Good air tightness;

Good compression set resistance;

Good wear resistance

|

Acrylonitrilebutadiene rubber Nitrile -butadiene Rubber Buna-N rubber |

| NR |

-40〜90℃ |

Good wear resistance;

Good elasticity;

Good tensile strength;

Good elongation

|

Natural rubber |

| SBR |

-30〜100℃ |

Good water resistance;

Good wear resistance;

Good weather resistance;

Good elasticity

|

Styrene-butadiene rubber |

| FKM/FPM |

-20〜200℃ |

Excellent heat resistance;

Excellent oil resistance;

Excellent chemical resistance;

|

Fluorocarbon |

Features

- Material: The sealing ring is made of high-quality black silicone foam. Silicone foam is known for its excellent resistance to heat, chemicals, and UV radiation, making it suitable for a wide range of environments.

- Compression and Flexibility: The silicone foam material allows the sealing ring to compress easily, ensuring a tight and effective seal. It also provides flexibility, enabling the ring to conform to irregular or uneven surfaces, preventing leakage or ingress of contaminants.

- Temperature Resistance: The silicone foam sealing ring exhibits exceptional temperature resistance. It can withstand both high and low temperatures without losing its sealing properties, making it suitable for applications where temperature fluctuations are common.

- Pressure Resistance: The sealing ring is designed to withstand varying levels of pressure. It maintains its sealing integrity even under high-pressure conditions, ensuring reliable performance in demanding applications.

- Durability: Silicone foam is a durable material that can withstand harsh operating conditions, including exposure to chemicals, oils, and solvents. It is resistant to degradation, ensuring the longevity of the sealing ring.

- Versatility: The Wholesale Black Silicone Foam Sealing Ring is available in different sizes, shapes, and configurations, catering to various sealing requirements. It can be customized or molded to specific dimensions, enabling it to fit different components and applications.

- Visual Appeal: The black color of the sealing ring offers an aesthetic advantage. It provides a clean and professional appearance while also helping to mask any dirt, dust, or wear over time.

These features collectively make the Wholesale Black Silicone Foam Sealing Ring a reliable and versatile choice for sealing applications in industries such as automotive, aerospace, manufacturing, and more.

Product Images

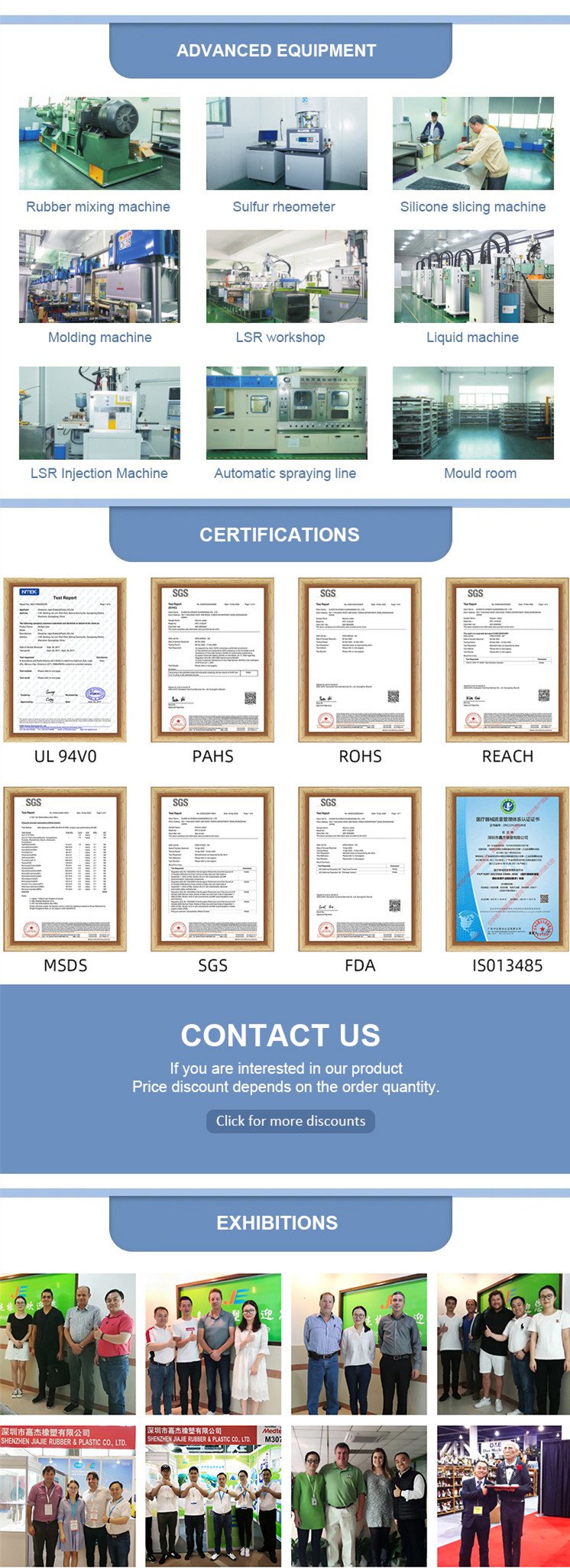

Our Factory