JY Machinery Specializes In Automotive Products Prototyping

Experienced That Successfully Lead You from Prototype to Production

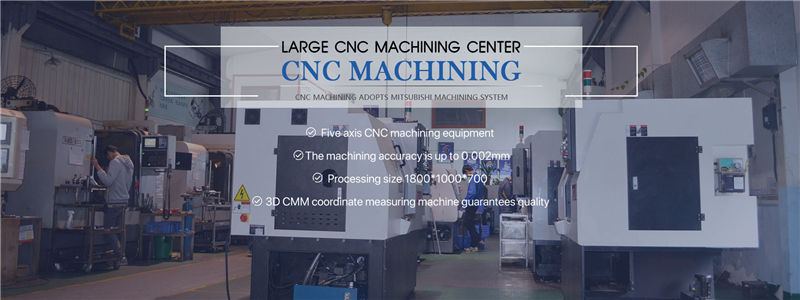

With more than 10 years of engineering and prototyping expertise, JY Machinery thrives in accelerating automotive product development with manufacturing on demand. We are committed to being your best full-service product development partner in the automotive industry. We focus on a variety of automotive prototyping and rapid manufacturing technologies, providing CNC machining, 3D printing, vacuum casting, injection molding, and sheet metal processing, which maintain a competitive edge with innovative service and highly skilled workforce. We’ll work together with you throughout every step of the automotive development and production process.

The custom automotive & motorcycle machining services that we can offer:

-

CNC milling

-

CNC turning

-

Multi-axis milling and turning

-

Automatic lathing

-

Custom Machine Parts

-

Injection mold

-

Metal Stamping parts

-

Welding& bending

-

Metal fabrication

-

Assembling service

Automotive Materials & Surface Treatments Available:

|

Material

|

Material type

|

Suface treatment

|

|

Aluminum or aluminum alloy

|

Aluminum6061,7075,5052,etc

|

Polishing, Plating Sandblasting, Laser engraving, mirror polish, Natural anodize, etc.

|

|

Steel

|

#45,Q235,Q345,etc

|

Polishing, Plating Sandblasting, Laser engraving, mirror polish, Zinc plating etc.

|

|

Stainless steel

|

SS303,SS304,etc

|

Polishing, Plating Sandblasting, Laser engraving, mirror polish, etc.

|

|

Plastic

|

POM, ABS, PE, HDPE, PVC, PP, acrylic, nylon, etc.

|

Polish, brush, mirror polish, etc.

|

|

Titainium

|

Gr2 titainium, Gr5 titainium, etc.

|

Polishing, Plating Sandblasting, Laser engraving, mirror polish, etc.

|

|

Brass

|

Brass, etc.

|

Polishing, Plating Sandblasting, Laser engraving, mirror polish, etc.

|

|

Copper

|

Copper, etc.

|

Polishing, Plating Sandblasting, Laser engraving, mirror polish, etc.

|

|

Bronze

|

Bronze, etc.

|

Polish, brush, mirror polish, etc.

|

|

Composite

|

FR4,G10,G11,GPO-3,Phenolic Cotton / Paper Laminated

|

--

|

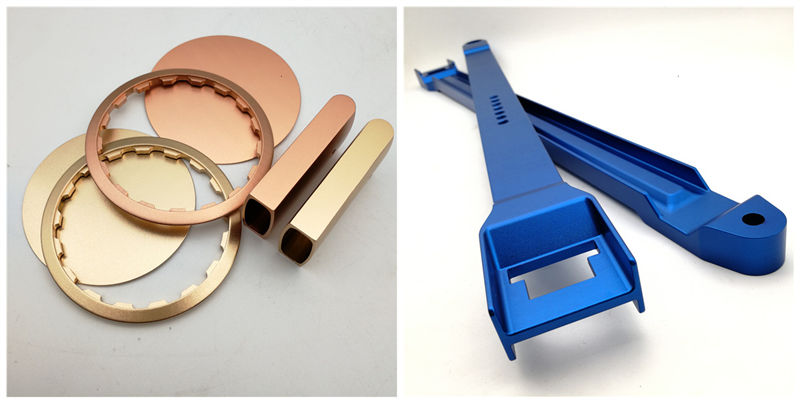

Note:The products shown here is only to present the scope of our business activities. We can manufacture custom parts according to your drawings or samples.

What you will get from our here?

* Competitive Price Of CNC Precision Machinery part

* Good Quality Assurance

* In Time Sampling & In Time Shipment

* Quality Guarantee

* Free Sample Can Be Provided Some Time

* Low MOQ

* Reply in 24 hours and fast quotaion

*Small MOQ acceptable

Contact us:

We make CNC parts according to customers' artwork, if you have any parts need to be made, please kindly send 2D and 3D artwork to us. And Please kindly mark dimension, tolerance, material, surface or hot treatment on 2D artwork, then we will according to it to calculate cost for you.

2D artwork format:JPG, PDF, DWG.

3D artwork format: IGS,STP,STEP.

FAQ:

Q:What raw materials can I use with CNC machining?

A:The raw materials we make process include:

1)Aluminum

2)Stainless Steel

3)Steel

4)Brass

5)Copper

6)Titanium

7)Engineer plastic,such as ABS, acetal, acrylic, PTFE, HDPE, nylon, PE, PEEK, PET,PFA, polycarbonate, polyethylene, polypropylene, polysulfone, polyurethane, PVC, etc.

8)Insulation materials,such as FR4,G10,G11,FR5,GP0-3,Phnolic Paper Laminate,Phenolic Cotton Laminate,etc.

Q:What are the benefits of CNC machining?

A:1.The number of tooling is greatly reduced, and complex tooling is not required for processing parts with complex shapes. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for the development and modification of new products.

2.The processing quality is stable, the processing precision is high, and the repeat accuracy is high, which is suitable for the processing requirements of the aircraft.

3.The production efficiency is higher in the case of multiple varieties and small batch production, which can reduce the time for production preparation, machine tool adjustment and process inspection, and the cutting time is reduced due to the use of the optimal cutting amount.

4.Machinable complex surface that is difficult to be processed by conventional methods, and even some unobservable machining parts.

Q:Can you CNC titanium?

Yes,Sure.The specific strength of titanium alloy products is very high in metal structural materials. Its strength is comparable to steel, but its weight is only 57% of steel. In addition, the titanium alloy has the characteristics of small specific gravity, high thermal strength, good thermal stability and corrosion resistance, but the titanium alloy material is difficult to cut and the processing efficiency is low.

Q:How much does it cost to CNC aluminum?

A:The cost of CNC machining aluminum is mainly determined by the size and structure of the product. If you want to know the specific cost of your product, please contact us for a quick quotation now.