Braided Flexible Metal Hose: An Engineering Marvel:

The braided flexible metal hose is a vital component in various engineering applications. It comprises a corrugated flexible pipe, braided wires, and joints. This versatile hose acts as a compensation, sealing, connecting, and damping element in diverse systems, such as gas transmission, infusion pipelines, length compensation, temperature compensation, position compensation, and angle compensation. It finds applications in aerospace, petrochemicals, mining, electronics, machinery, shipbuilding, medical and health, textile electronics, energy, and building sectors.

Construction of Flexible Metal Hose Assemblies:

Connector:

Our special elbow joints can be customized to achieve a 90° elbow connection or any desired bend angle according to customer requirements. The elbow joints are available in threaded, welded, male thread connectors, or can be customized as per specific requests.

Inner Core: Corrugated Stainless Steel:

The flexible metal hose utilizes high-quality stainless steel materials, including options such as 304, 321, and 316L. The stainless steel bellows are formed into corrugations that run parallel to each other, providing excellent flexibility and durability. Depending on the requirements, the hose can be made with either annular corrugations or spiral corrugations.

Outer Core: Braided Stainless Steel Layers:

Our braided flexible metal hose is reinforced with single or double layers of braided stainless steel. These layers are typically made from the same stainless steel materials as the corrugated bellows, including 304, 321, and 316L stainless steel. The braided layers play a crucial role in enhancing the hose's strength and offering additional shielding against external factors.

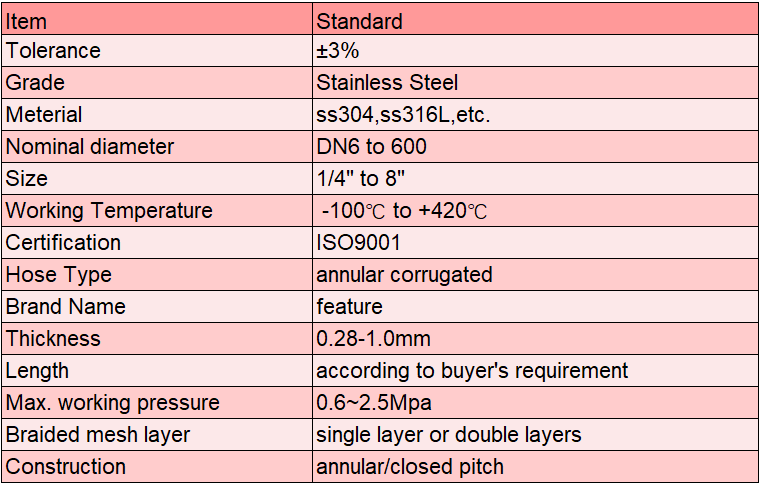

Product Standards:

Advantages of Our Elbow Joint for Flexible Metal Hose:

Versatile Design: Our elbow joints are suitable for complex indoor and outdoor environments, providing reliable performance under challenging conditions.

Corrosion Resistance: The elbow joints are resistant to oxidation stains, maintaining their appearance and effectively preventing corrosion when in contact with water.

Superior Sealability: Our elbow joints are meticulously designed and manufactured to ensure excellent sealability, minimizing the risk of leaks and enhancing overall system performance.

Robust Performance: With high-pressure and high-temperature capabilities, our elbow joints for flexible metal hoses are designed to endure extreme conditions, providing long-lasting performance.

Reliable Supplier with Customization Services:

At our company, we prioritize delivering high-quality products and maintaining customer satisfaction. We offer a range of customization options to meet specific requirements. These include customized design specifications such as internal diameter (I.D.), outer diameter (O.D.), length, connection types, materials, printed tags, packaging, and more.

Our Commitment to Quality:

As an ISO9001 certified company, we uphold the highest quality standards throughout our manufacturing processes. We ensure on-time delivery of standard products and offer a reliable, qualified, and stable supply of components. Rest assured, all our products undergo rigorous quality checks before shipping.

Installation Guidelines:

Flexible metal hoses can be installed horizontally, vertically, or diagonally, although vertical installation is preferable. It is advisable to avoid installing them near wheels, and if necessary, a baffle can be used to ensure optimal performance.

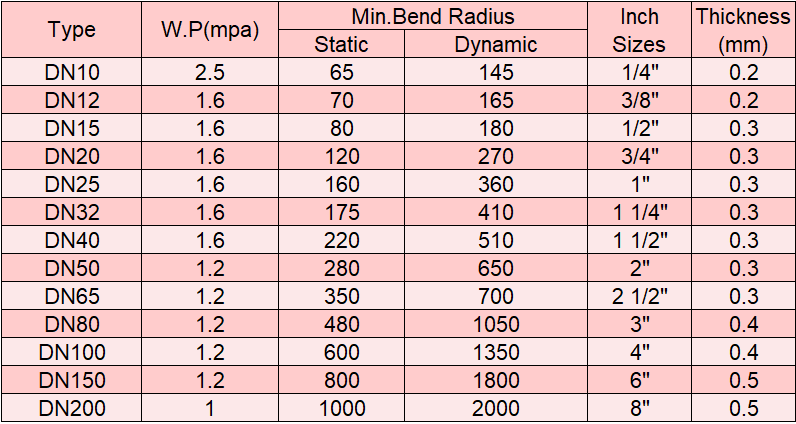

Flexible Metal Hose Performance Parameters As Below:

Custom Services at Your Disposal:

Specific Design Customization: We provide customized solutions catering to your specific requirements, such as I.D., O.D., length, connection types, materials, printed tags, packaging, and more.

OEM/ODM Service: Our team can fulfill your desired specifications and offer custom-designed prints based on your needs.

Sample Order: To ensure quality satisfaction, you have the option to purchase a free sample order to test the product before placing a full order.

Conclusion:

Choose our custom elbow joints for flexible metal hoses and experience enhanced pressure and corrosion resistance. Our commitment to quality, customization, and exceptional performance makes us the reliable partner you can count on. Contact us today to explore the full potential of our elbow joints and elevate your applications to the next level of efficiency and reliability.