Cylindrical Battery Semi-Automatic Winding Machine

Description

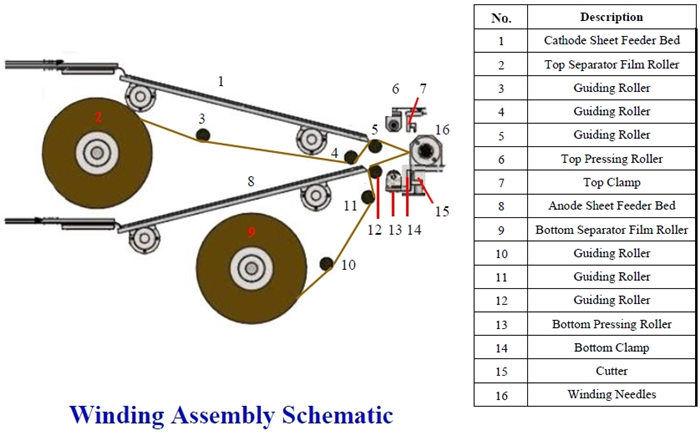

The machine is mainly used for the precision winding of core of the cylinder battery.

The working process is as follows: manually guide the cathode and anode electrodes into the winding part, and separated stacking with the separator, and the winding will be carried out according to the requirements of the process, automatically attaching the termination tape, and the cell will automatically feed.

Function and Features

1. Adopt single needle counterwinding needle structure.

2. Manual lead-in electrode, automatic winding, automatic change needle, automatic tape ending tape and automatic unloading;

3. The adhesive tape adopts the horizontal paste (the tape is perpendicular to the tab), the adhesive is flat, and the adhesive position can be controlled accurately without tightening the cell; the adhesive is stable and reliable;

4. winding needle speed was adjustable;

5. Two rolls of separator active to unwinding, tension push switch control technology can adjust tension automatically during winding.

6. It has a dust removal device;

7. Separator outer pack end.

8. The cell after winding without damage, core pulling and electrode dislocation phenomenon;

9. Easy to operate,adjust and replace;

Technique Standard

|

Model

|

TMAX-winding004

|

|

Voltage

|

AC220V,1.5KVA,50HZ

|

|

Compressed air

|

0.4-0.6MPa

|

|

Productive capacity

|

8PCS/min

|

|

Weight

|

About 500kg

|

|

Size

|

1660mm*1300mm*1570mm(Does not include the outstretched length of the electrode.)

|

|

Winding needle specification

|

Φ1.5mm-Φ9mm(With one set for free, customized)

|

|

Applicable outer diameter of the cell

|

Φ12mm-Φ32mm

|

|

Equipment capacity

|

6~15 pcs/ min (according to the length/width of the electrode)

|

|

Winding precision

|

when the electrode is guaranteed to meet the following conditions:

The width error is less than ±0.2mm;

The bending error of "S" is less than ±1mm/500mm;

The tower shape error of the separator is less than ±0.2mm;

|

|

The winding precision can be satisfied

|

The alignment error of the separator is less than ±0.5mm;

The alignment error of electrode is less than ±0.5mm;

It can realize the negative electrode wrap the cathode electrode , the separator wrap negative electrode, and the alignment of the finished product section is ±0.5mm

|

|

Qualified rate

|

≥98% (excluding equipment factors)

|

|

Warranty

|

One Year limited warranty with lifetime support

|

Material specifications (unit: mm)

|

Material

|

Length

|

Width

|

Thickness

|

Inner diameter

|

Outer diameter

|

|

Cathode electrode

|

250~2500

|

18-63

|

0.1-0.2

|

|

|

|

Anode electrode

|

250~2500

|

18-63

|

0.1-0.2

|

|

|

|

Separator

|

Roll material

|

20-65

|

0.016-0.045

|

76.2

|

250

|

|

Termination tape

|

Roll material

|

10-50

|

0.01-0.035

|

76.2

|

150

|

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.