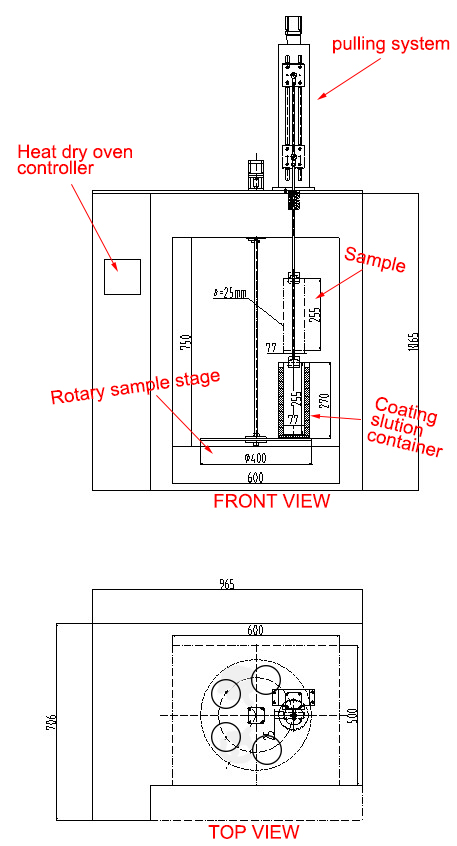

Dip Coater (1-200 Mm/Min) With 124 L Temperature Chamber And Touch Panel Controller For Large Substrate Up To 16"X 9"

Specifications:

|

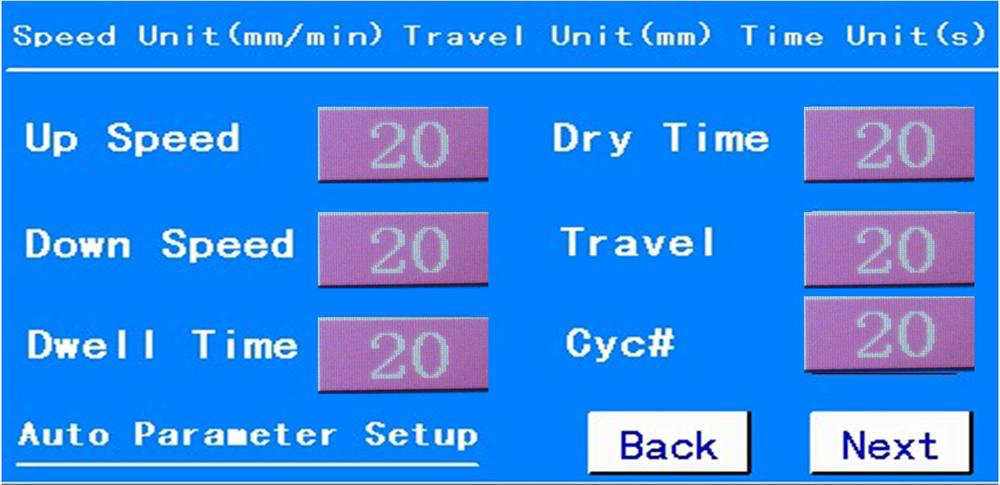

Control Panel

|

· Working Voltage: 110-240V AC

· Max. Power Consumption: 50W

· Detachable Digital Controller offers flexibility

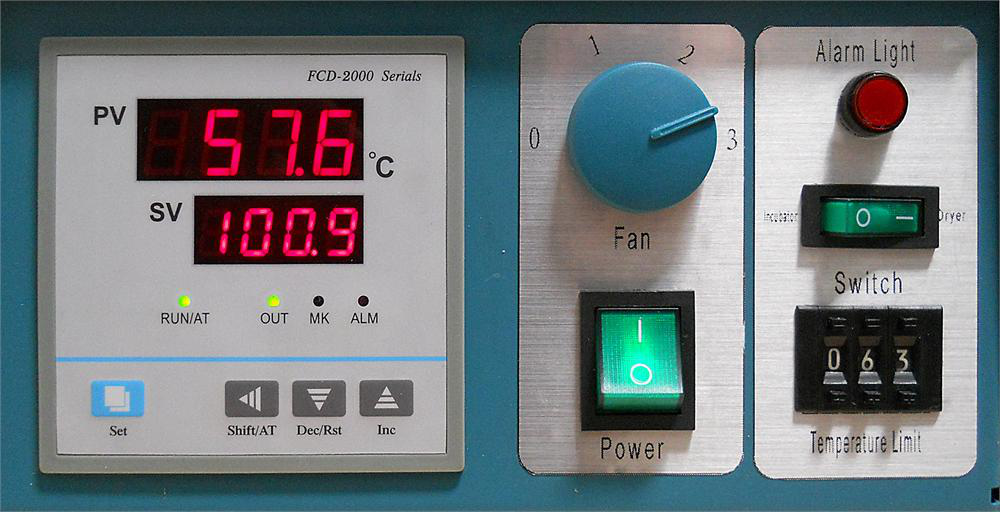

· Programmable temperature controller, Forced air fan power adjustor, Temperature limit & alarm indicator, Incubate and dry function switch are included. (Please see the second picture below for details.

|

|

Traveling Distance

|

0-250 mm Adjustable

|

|

Dipping/Pulling Speed

|

1-200 mm/min Adjustable

|

|

Max. Working Temperature

|

100°C (+/- 1.5°C accuracy)

|

|

Solution Container

|

· One Polypropylene dip tank is included with dimensions of 17.25''(W) x 2''(D) x 9.5'(H)

· Optional: temperature controlled recirculating pump for the coating slurry can be added inside chamber and tank at extra cost.

|

|

Max. Sample Size

|

16" x 9"

|

|

Max. Sample Weight

|

5 kg

|

|

Dipping/Pulling Motor

|

Stepping Motor

|

|

Oven

|

· Working Voltage: 208-240V AC

· Max. Power Consumption: 2300W

· Chamber Dimensions: 500mm(L) x 450mm(W) x 550mm(H)-- 124 Liter

· Inner Material: Stainless Steel

|

|

Product Dimensions

|

636mm(L) x 680mm(W) x 915mm(H)

|

|

Compliance

|

CE Certified

|

|

Warranty

|

One year limited with lifetime support

|

|

Application Notes

|

· In order to get better film coating, the substrate shall be treated by plasma cleaner (Please click on the first picture below for more information)

· Use ultrasonic processor to disperse nanopowder or homogenize solution to get better coating (Please click on the second picture below for more information)

|

|

Net Weight

|

91 kg (200 lbs)

|

|

Shipping Dimensions

|

40"(L) x 40"(W) x 60"(H)

|

|

Shipping Weight

|

182 kg (400 lbs)

|

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.