Introduction

The

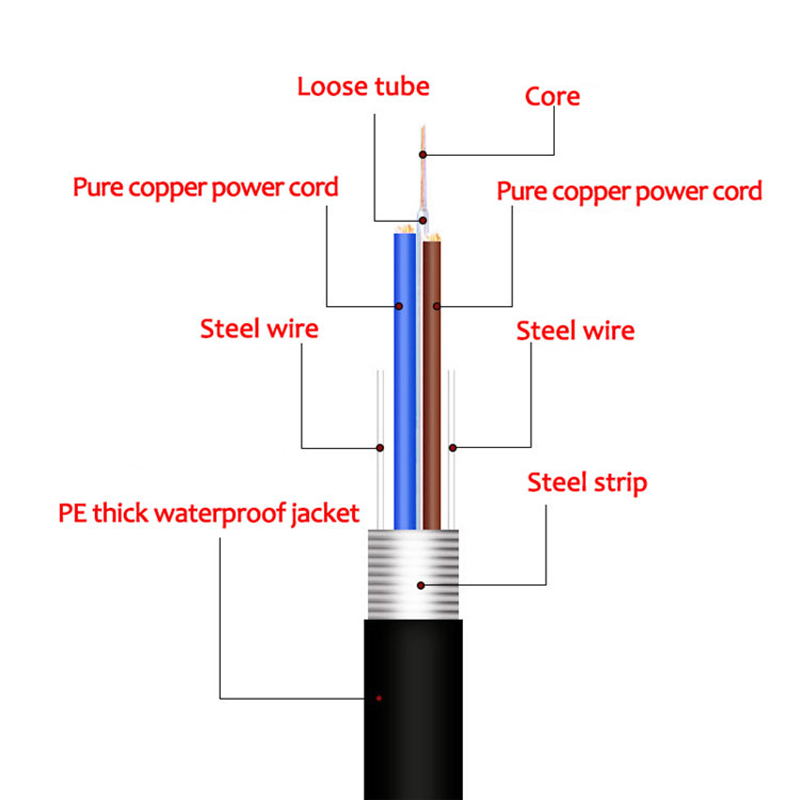

structure of opts-electric hybrid cable is to insert a 250μm fiber into a loose

tube made of high-modulus material, and the loose tube is filled with a

waterproof compound. The center of the cable core is FRP or metal reinforcement

(some structures require a layer of PE underlay on the reinforcement). The wire

and the loose tube (and the filling rope) are twisted around the central

reinforcing core into a compact and round core, and the gap in the core is

filled with a water blocking filler. The double-coated plastic strip (PSP) is longitudinally

extruded and extruded into a polyethylene or low-smoke halogen-free (LSZH)

jacket.

Features

-

Has good flexibility and mechanical properties.

-

Photoelectric integration, fully saving pipeline resources.

-

The cable section and the cable section maintain a relatively independent

structure for easy introduction, extraction and connection during installation.

-

Consolidate

multiple power lines, telephone lines, TV lines, network lines, monitoring

lines, data lines, etc., saving costs.

-

Large operating temperature range.

-

Large construction temperature range.

-

The diameter of the cable and the bending radius are small, and the

colleague-compatible optical signal transmission and power transmission can be

freely installed in a small space.

Technical advantages

Optimize transmission line design and save energy.

Photoelectric integration, transmitting information while transmitting

electrical energy, and can detect the working state of the line.

The optical fiber is compounded in the wire to prevent fiber breakage and fiber

breakage caused by lightning on the ground.

It will not cause electric cable corrosion or cable breakage or fiber breakage

caused by field strength.

There is no hidden danger caused by adding extra line load to the original

route.

Structural

parameters

|

Project

|

Skills

requirement

|

Remarks

|

|

Allowable

bending radius (mm)

|

Dynamic

|

30D

|

|

|

|

Static

|

20D

|

|

|

Allowable

tension (N)

|

Short

term

|

3000

|

|

|

|

Long

term

|

1500

|

|

|

Allowable

crushing force

(N/100mm2)

|

Short

term

|

3000

|

|

|

|

Long

term

|

1000

|

|

|

Range

of working temperature

|

Wire

|

-15℃~+70℃

|

Comply

with GB5023-1997

|

|

|

Other

materials than wires

|

-40℃~+70℃

|

|

|

Water

blocking / waterproof performance

|

Long-term

immersion in water does not seep

|

Except

for the inner conductor of the wire

|

|

|

|

No

leakage

|

|

Construction

temperature range

|

-20℃~+60℃

|

Except

for wires

|

|

|

0℃~+60℃

|

Wires

|

|

Weight

|

347kg/km (RV-2*2.5mm)

382kg/km (RV-4*2.5mm)

502kg/km (RV-6*2.5mm)

628kg/km (RV-8*2.5mm)

|

|

|

Mechanical

behavior

|

Cable

tensile, flattening, impact, repeated bending, torsion, winding, wear, etc.

meet YD/T901-2001 test requirements.

|

|

Applicable

laying method

|

Suitable

for laying pipes, channels, cable trenches, overhead, direct burial, etc.

|