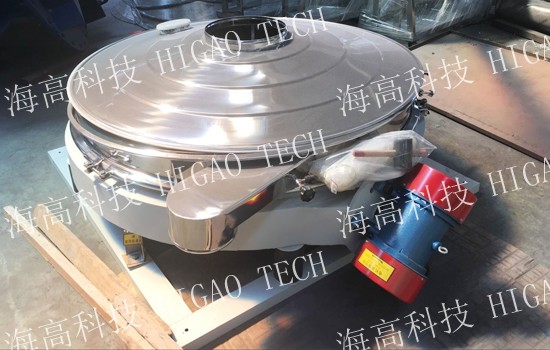

Direct discharge vibrating screen machine is used to remove impurities and loosen materials of granules and powder in food, chemical, pharmaceutical industries.

1. Introduction:

Direct discharge vibrating screening machine is used to remove impurities and loosen the materials in the powder production line.

Now it is mainly used for coarse separation and precise separation of granules and powder in flour, starch, washing powder, metal powder, additives, chemical industry, non-mining and other industries. With large output capacity, it is easy to connect to production lines.

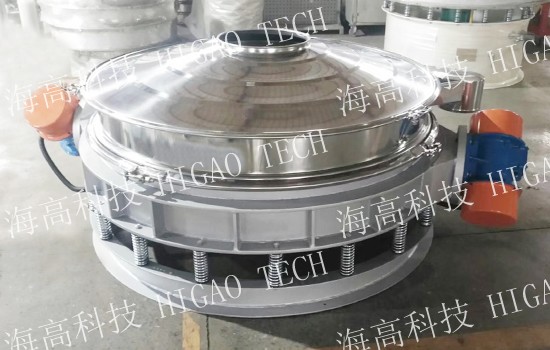

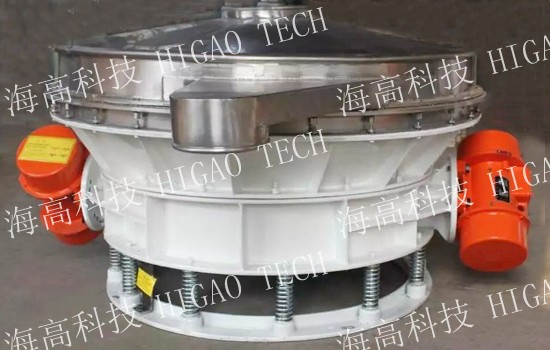

The vibrating structure is of two types: single motor and double motors. The moving trails of the materials can be adjusted with various movement, which increases the usability of direct discharge vibrating screening machine.

2. Working principle:

Two sets of eccentric blocks (unbalanced eccentric blocks) at the upper and lower ends of the shaft can change the rotating movement of the vibrating motor into a combined mixed acting force with horizontal, vertical or inclined or centrifugal movement. Then transmit this mixed force to the surface of the sieve, so as to achieve the separating purpose finally.

By changing the phase angle and weight of the upper and lower eccentric blocks to change the excitation force and the movement tracks of the materials.

3. Features:

1.Made of stainless steel 304(SUS304#), beautiful and durable.

2.Compact designed structure with small dimension, easy to move.

3.Easy to disassemble and assemble, easy to clean.

4.Without sanitary dead ends, conform with food grade and GMP standard.

5. It can carry out 24 hours continuous working with low noise.

6. Low energy consumption with high working efficiency.

7. Materials stay in the screening machine for a short time, the material will discharge direct and very quickly, so it can handle large capacity.

8. Fully closed structure and good sealing to prevent liquid leakage and dust flying to be environment-friendly.

9. Upper discharge port/exit can be adjusted within 360 degrees to match installation in working site.