Summary:

W5 Direct Reading OES Spectrometer bring in the advanced technology from Europe. It is the 4th generation Arc/Spark-OES with high performance lowing operating cost for metal analysis and this is the latest research and development of detection equipment. The overall optical design has been enhanced, and with improvements of CMOS technology used to further improve the performance of the W5 while retaining the major benefit of earlier units. The CMOS spectrometer is not only contain the full spectrum characteristics of CCD spectrometer but also the extremely low detection limit for non-metallic elements such as C, S, P, B, As, N etc. The operation is simple and easy to learn. The test result is stable and accuracy. It is a good choice of all common metals for incoming and outgoing product quality control.

Application:

W5 Direct Reading OES Spectrometer is used for applications in metal elemental analysis, trace element analysis for science and industry like Metallurgy, Foundry, Mechanical Engineering, Scientific Research, Product Inspection, Automobile, Petrochemical Engineering, Shipbuilding, Electrics, Aerospace, Nuclear Power, Metallic and Nonferrous Metallic Smelting, Processing and Recycling. It is including full element analysis range, but at same time the element analysis amount can be bespoke.

Large Steel Plants Where needs are at around10 PPM levels or elements like C, N, Cr, S, P etc.

Testing Laboratories: Commercial testing laboratories, Universities and colleges

Pure metal applications purity Al, Pb, Zn, Mg etc. – most industrial users

Regulatory compliance Very low LODs to control Pb, Cd, As etc.

Foundries which need a quick analysis near the furnace

Manufacturing Facilities

Warehouse material identification

Base: Fe, Cu, Al, Ni, Co, Mg, Ti, Zn, Pb, Sn, Ag, Mn, Cr etc

Detection Matrices:

Iron(Fe) and its alloys (Steel alloy, Cast iron, Fe-Low alloy, Fe-Cr steel, Fe-Cast iron, Fe-Cr-cast, Fe-Mn steel, Fe-Tool steel etc.)

Aluminium(Al) and its alloys (Al-Si alloy, Al-Zn alloy, Al-Cu alloy, Al-Mg alloy, Pure-Al alloy etc)

Copper(Cu) and its alloys (Brass, Copper-Nickel-Zn, Aluminum Bronze, Tin-lead Bronze, Red Copper, Be-Bronze, Si-Bronze etc)

Nickel(Ni) and its alloys (Pure Ni, Monel metal, Hadtelloy Alloy, Incoloy, Inconel, Nimonic etc)

Cobalt(Co) and its alloys (Co-orientation, Low Co alloy, Stellite 6,25,31, Stellite 8,WI 52, Stellite 188, F)

Magnesium(Mg) and its alloys (Pure Mg, Mg/Al/Mn/Zn-alloys)

Titanium(Ti) and its alloys

Zinc(Zn) and its alloys

Lead(Pb) and its alloys

Tin(Sn) and its alloys

Argentum(Ag) and its alloys

Manganese(Mn) and its alloys

Chrome(Cr) and its alloys

Small sample, special size sample and wire detection

Features:

|

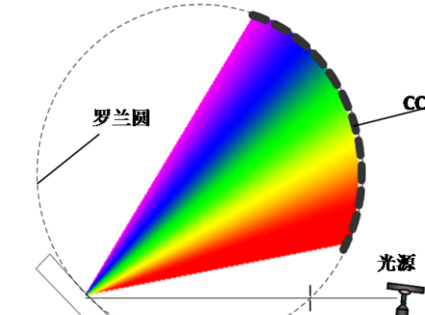

1. Superior Performance Optical System

①Paschen-Runge Structure has concave grating and full spectrum coverage, it can be satisfied with customers demand for elements.

②The direct optical technology and optical devices are made of MgF, to guarantee the best performance in the UV region.

③High resolution of Multi-COMS read-out system, lower dark current, better detection limit, higher stability and stronger sensitivity.

④The optical system adopts vacuum constant temperature light room, it can realize that light path through, to eliminate optical path loss, to improve test limit, and the results of test is more accurate, its reproducibility and long-term is perfect.

|

|

|

2. Intelligent Digital Excitation Light Source

①Fully digital intelligent composite light source DDD technology can have superior analytical performance.

②The compact design and semiconductor control technology, and make light source have better stability and stronger reliability.

②HEPS can excite parameter adjustment and fully satisfied different matrix, different samples and the demand of analytical elements.

|

|

|

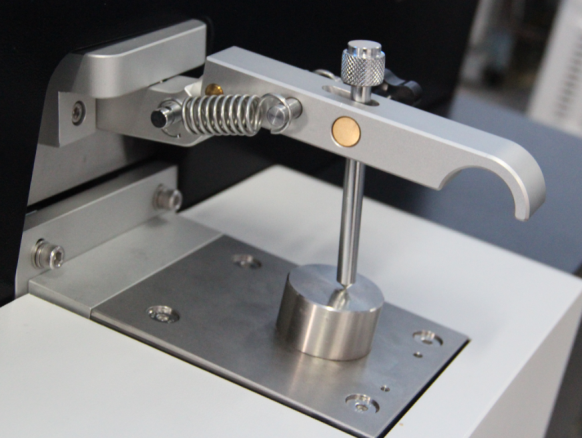

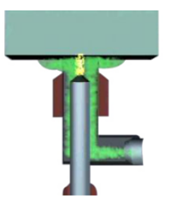

3. Intelligent Sample Inspire Stand

①The excitation station can lead laser into the optical system directly.

②The open electrode frame design, it can adjust sample folder so as to analyze all kinds of shapes and sizes.

③To transform electrode can have the better performance for small samples and analysis

of complex geometry samples.

④Video recognition technology can ensure the safety of sample excitation station and can

monitor the panoramic view of sample station.

|

|

|

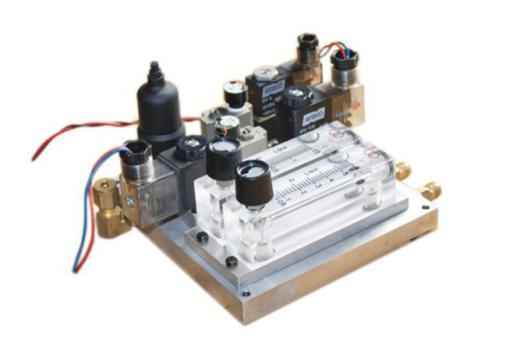

4. Intelligent Integrated Gas Channel Block

①The design of intelligent argon flow and the detection of dust collection.

②The special argon injection technology has effectively eliminate excitation process

plasma drift and can ensure CMOS detector to observe the high temperature light signal

and to improve its accuracy and stability.

③After excitation, the pulsed argon purge improves the effective of dust removal, so it can

improve the instrument’s short-term and long-term stability.

|

|

|

5.Intelligent Vacuum Measurement and Control

①The vacuum system is program control completely, while ensuring the vacuum to reduce vacuum pump running time.

②Two-level setting, under the circumstance of the instrument is not running, the instrument needs to open the standby of vacuum operation status.

③Multi-level vacuum isolation measurements and increasing the oil filter device, and it can keep the optical components working in reliable environment.

|

|

|

6. Leans Cleaning Device

①The stainless steel vacuum valve has a better isolation effect in cleaning the lens.

②The design of single lens can easily disassemble.

③Cross mechanism device can protect optical system effectively under the circumstance of no quarantine.

|

|

|

7. Computer and Read-out System

①The computer and cellular phone (PAD) can display synchronously, it is easy to operate for panel.

②High-performance DSP and ARM processor, it has high speed data collection and control function. And it can detect the model of room temperature, vacuum temperature, argon pressure, light source’s conditions.

③The anti-jamming performance is better, the external computer upgrade is related to configuration of instrument, so the instrument has a better applicability.

④The data can remote transformation to realize network and it is convenient to monitor and control for the instrument operating status.

⑤And the results can have real-time monitoring and the function of printing reports can customize for the users. Meanwhile the data can use cloud print.

|

|

|

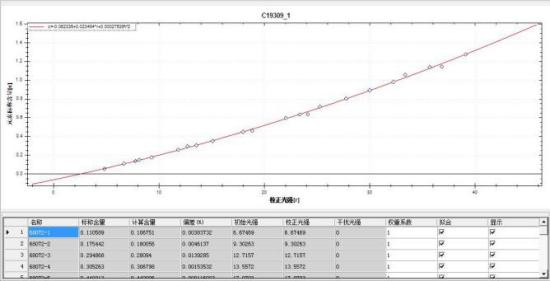

8. Friendly Analysis Software

①The dedicated spectrum software meets international spectrometer production standards, the operation interface has user-friendly design and function standardization.

②The software in the instrument has equipped with multiple factory calibration curves and many material analysis methods and advanced solutions.

③According to users’ material requirements, the staff members can extend upper limit and lower limit of the standard curves on site.

④The working curve adopts international sample, it was pre-made the working curve, according to its needs to extend the range, every curve is made of more 10 samples to generate and automatically eliminate interference.

|

|

|

9.Other features

①It can detect elements including that C, P, S, N and it is suitable for a variety of metal base. Such as iron-based, aluminum base, copper base, nickel base, chromium base, titanium base, magnesium base, zinc base, Tin base, lead-based, cobalt base, sliver base and manganese-based and so on. Full spectrum technology covers the whole range of elemental analysis, the customers can choose channel elements by themselves.

②The design of argon gas circuit is reasonable, it makes argon washing’s time is shorten when the sample excitation. In order to save argon for customers, this kind of design is very reasonable.

③The construction of light room, it makes vacuum room’s volume small, the rate of vacuum arrives half of the normal spectrometer’s. Its optical path automatically calibrated and optical system automatically goes on line scan, it ensures that receiving is right and to eliminate complex the crest scan job. The instrument can automatically identify specific lines and compare with the old one, it can ensure the drift position and to find out the analysis line’s present location of pixel.

④The rate of analysis is fast, all elements in the channel can be tested within 20s. According to different analysis materials, the instrument can get better analysis results in short time by setting the pre-burn time and marking line.

⑤Solid absorption trap can prevent oil and gas from polluting the light chamber and improve its stability.

⑥It adopts tungsten material electrode, it makes electrode longer life, the electrode has the purge function automatically, it is easier to clean up the electrode.

⑦Standardized parameter modification.

⑧Control sample correction function.

⑨The core device are all original imported, in order to promise the products’ quality.

|

Parameter:

|

Item

|

Index

|

|

Optical system

|

|

Optical structure

|

The Paschen Runge construction full vacuum type optics system

|

|

Room temperature

|

35℃±0.5℃

|

|

Wavelength range

|

130-800nm

|

|

Focal length

|

400mm

|

|

Grating line

|

2400m1/mm

|

|

First order spectral line dispersion rare

|

1.2nm/mm

|

|

Detector

|

Multi block high performance linear CMOS array

|

|

Average resolution ratio

|

10pm/pixel

|

|

Excitation table

|

|

Gas

|

Rushing argon(99.999%)

|

|

Argon flow rate

|

When excited: 3-5L/min

Standby time: no need for standby traffic

|

|

Electrode

|

Tungsten electrode technology

|

|

Purge

|

Automatic purge function

|

|

Make up

|

Thermal deformation self-compensation design

|

|

Analyze the gap

|

Sample stage:3.4 mm

|

|

Excitation light

|

|

Type

|

HEPS

|

|

Frequency

|

100-1000HZ

|

|

Discharge current

|

1-400A

|

|

Special technology

|

Optimization of discharge parameters design

|

|

Pre -combustion

|

High-energy pre-combustion technology

|

|

Processor

|

High end ARM, high-speed data synchronization acquisition and processing

|

|

Data collection system

|

|

Interface

|

Ethernet data transmission based on DM9000A

|

|

Power

|

220VAC 50/60Hz(Customized)

|

|

Others

|

|

Base

|

Fe, Cu, Al, Ni, Co, Mg, Ti, Zn, Pb, Sn, Ag, Mn, Cr etc

|

|

Power consumption

|

Maximum:750W standby:40W

|

|

Working temperature

|

10-35℃(temperature ≥5°C)

|

|

Working humidity

|

20-85%

|

|

Dimension

|

860mm(L)*680mm(W)*438mm(H)

|

|

Weight

|

About 100Kg

|