Bonve rotary Lobe Pumps for beer

Beer is rich in nutrients. It is a refreshing drink with a good balance of various health-care substances and nutrients (such as carbohydrates, protein, vitamins and minerals). The nutrients of beer are all in a water-soluble state, which is easily used and absorbed by the human body. Use low speed during transportation to avoid damaging the nutrients in the wine.

The process

The beer wort is removed from the malt hull

in the filter tank before being pumped into the boiling pot, and hops and sugar

are added. In a boiling pot, the mixture is boiled to absorb the hops and to

color and disinfect. After boiling, the beer wort added to the hops is pumped

into the swirling tank to remove unwanted hop residues and insoluble proteins.

The pure beer wort is pumped out of the cyclone sedimentation tank and cooled

into a heat exchanger. Subsequently, the yeast is added to the beer wort and

begins the process of fermentation.

The solution

Bonve offers its rotary lobe pumps to

transfer beer wort due to below advantages

Non-contacting pump head design with all metallic pumped media wetted components

manufactured in 316L stainless steel.

-

Cost effective easy maintenance

Low running and maintenance costs and easy access to pump head minimizing downtime, results in a reduced life-cycle cost.

Maximized efficiency a chieved with optimum pump head geometry by maintaining high accuracy

and repeat-ability of component part manufacture.

Minimal damage to extremely shear sensitive culture media, such as yeast slurries.

Occupies considerably less floor space than other pump technologies.

Temperatures upto 200ºC

How pump works?

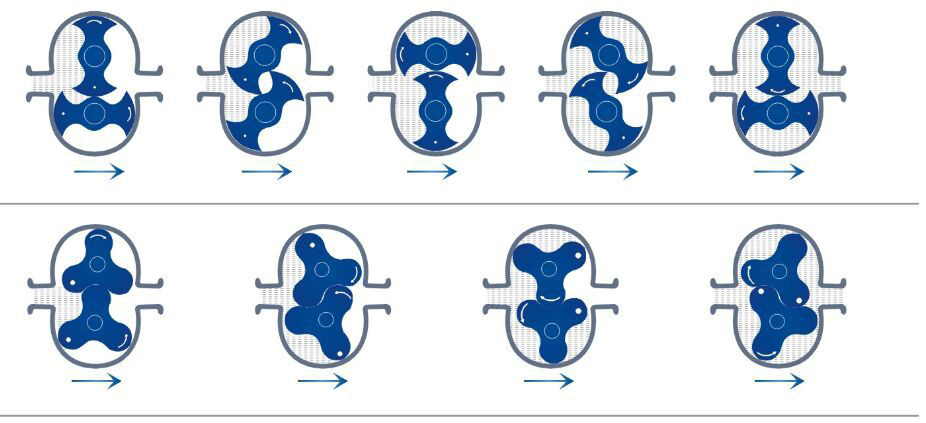

The even rotation of the rotor pair creates a vacuum on the

priming side of the pump, which can be defined by the direction of rotation of

the drive. This vacuum draws the liquid into the pump chamber. With further

rotation, the pumped medium is conveyed past the pump wall into the pressure

area. Up to six chamber charges are displaced with each drive rotation– depending on the rotor type. When the rotor is at a

standstill, the pump seals off almost

completely.

Pump

main structure

Pump

structure advantage

Pump main technical parameter

|

Model

|

Displace

-ment

(L/r)

|

Rotation

speed

(r/min)

|

Flow

rate

(M³/h)

|

Dis.

Pre.

(Mpa)

|

Electrical

power

(Kw)

|

Suc.

Pre.

(Mpa)

|

Dia.

of inlet

and

outlet (mm)

|

|

25BV6 /12-2

|

0.15

|

20-600

|

2

|

0.1-1.2

|

1.1-2.2

|

-0.095

|

25

|

|

40BV6 /12-5

|

0.32

|

20-550

|

5

|

0.1-1.2

|

1.5-4

|

-0.095

|

40

|

|

50BV6 /12-10

|

0.65

|

20-550

|

10

|

0.1-1.2

|

2.2-7.5

|

-0.095

|

50

|

|

65BV6 /12-20

|

1.74

|

20-550

|

20

|

0.1-1.2

|

4-15

|

-0.095

|

65

|

|

80BV6 /12-30

|

2.48

|

20-550

|

30

|

0.1-1.2

|

5.5-22

|

-0.095

|

80

|

|

80BV6 /12-40

|

3.65

|

20-550

|

40

|

0.1-1.2

|

7.5-30

|

-0.095

|

100

|

|

125BV6 /12-50

|

4.60

|

20-550

|

50

|

0.1-1.2

|

11-45

|

-0.095

|

125

|

|

125BV6 /12-70

|

6.10

|

20-550

|

70

|

0.1-1.2

|

15-55

|

-0.095

|

125

|

|

125BV6 /12-80

|

7.63

|

20-550

|

80

|

0.1-1.2

|

18.5-75

|

-0.095

|

125

|

How

to choose our pump?

|

Selection Guideline

|

|

Liquid

name:___________

|

|

Viscosity:_______cp Density:_______ Temperature:_____℃ PH

value:________

|

|

Solid content:_______ Max. size of particle:_______

|

|

Capacity: Max. required__________ L/H Working required__________ L/H

|

|

Discharge pressure: Max. required__________Mpa Working required__________ Mpa

|

|

Connection type required: Thread [ ] Clamp [ ]

|

|

Installation type: Fixed [ ] Movable [ ]

|

|

Voltage:____ V Frequency: _____Hz

|

|

Liquid contact material: SS304 [ ] 316 [ ] 316L [ ]

|

|

Special

request_____________________________________

|

|

Order qty.

|

Thanks

for your interest into our rotary lobe pump, hope we can solve your pumping

problem during your beer production. Contact our sales engineer - Mr. Andre

Chen for a pump solution.

Email: bvsales2@bonvepumps.com

Tel :

0086-574-87769810

Mobile: 0086-15888591452