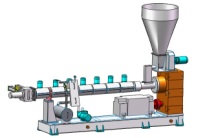

EPS foam pelletizer has the feature of reasonable design, high automation, advanced technology ,high efficienty and energy saving.It can directly produce pellets at normal temperature,no pollution. The pellets are bright and uniform, export to Japan and South Korea, has been widely praised by users.

The EPS ingot pelletizing line is composed by screw feeder,extruder,screen changer,water ring cutting system ,fan delivering and controlling system.

1. Feeder

Material:Stainless Steel

Silo capacity:200L

Feeding type:Screw feeding

Capacity :≥400kg/h

Feeding power:AC1.5kw

Feeding control:Inverter ABB

2.Extruder

Barrel, Screw material:38CrMoAl

Barrel configuration:Spiral slotting and forced water cooling in feed section

Screw configuration:High efficiency exhaust and mixing

Central hight:1200mm

Screw diameter:150mm

L/D=28

Barrel heating:7sets

Barrel heating power:≈48kw

Barrel heater:Ceramic heater

Heater cover:Stainless conver

Barrel fan cooling:7×180w

Screw rotation speed:90rpm

Gearbox:High efficiency hard tooth gearbox

Driving power:132kw with inverter

Driver: Direct coupling of high efficiency coupling

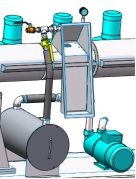

3.

Vacuum exhaust 1 set

Vacuum pump:3kw

High efficiency exhaust to ensure material quality

Exhaust form: vacuum water filtration

Vacuum chamber: special design

Vacuum cover: aluminum alloy

Vacuum tube: high temperature and high pressure rubber tube

4.Screen Changer

Model: Phi 250 single plate

Filter area: circle (phi 250) mm

Under maximum pressure melt: less than 20Mpa

Filter screen: double station

Double station mobile speed: less than 2 seconds

Material: 38CrMoAl

Heating power: 16KW

2 high pressure oil pipe

5. water ring mold

Mold material: 40Cr

Template material: 38CrMoAl

Discharge hole: 3 X 48

Heating power: 6kw

Special heating of template core

Cover material of water ring cover: aluminum alloy

6. water ring cutting system

water ring cutting system

Water ring cover material: stainless steel

Water circulation pump: 4kw

Granulating motor: 3kw

Number of cutters: 4

Grain cutting control: ABB variable frequency speed regulation

Movement of water ring: roller movement

2, tank + water tank

Water tank and water tank material: stainless steel

Water level control: automatic high water level overflow

3. Centrifuge dehydrator

Dehydrator material: stainless steel

Power of the dehydrator: 3kw

Speed: 1480rpm

Special design of dehydrated rotor and blade

Special design of dehumidification fan

Couplings: Lovejoy, USA

Bearing: SealMaster, USA

7.Fan delivery system

8. Electric controlling sytem

EPS ingot pelletizer working video