Product Item: Four Rollers Hydraulic Rolling Machine

1. Main Features:

1.Four Roller Plate Rolling Machine streamlined designed originated from EU, adopting whole welding and annealing treatment of the machine frame to eliminate stress.

2.Adopting Germany Bosch Rexroth integrated hydraulic system, hydraulic drive, stable and reliable, and can effectively reduce the problems caused by oil leakage.

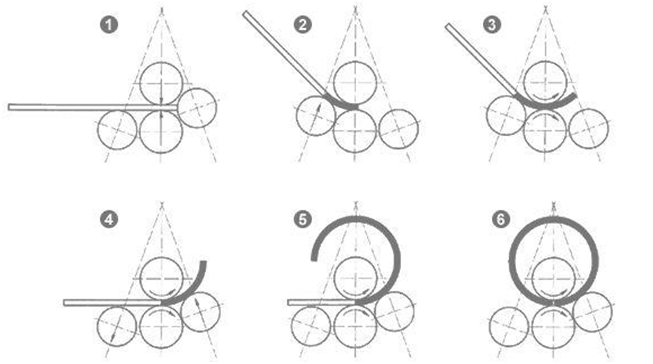

3.Fixed top roller, bottom roller driven by hydraulic oil cylinder, left and right side rollers is driven by hydraulic pistons for diagonal movement.

4.CNC control, three group digital readout show the position of working roller, high accuracy and good roundness, material aligning is convenient and accurate, avoid the wrong side phenomenon.

5.Hydraulic Drop-end for easy removal of finished ferrule

6.SAE 1050 Quality Certificated induction hardened forged steel rollers with high strength

7.Hydraulic balancing system with self-tapping conical bending device is convenient for bending cone.

8.Permanent lubrication technology (bearings needn’t be oiled within service life), easy to add handling device, feeding device and material supporting device.

9.Consistently tightly clamp the top and bottom rollers during rolling process to prevent plate sliding

10.Blade clearance quick adjusting mechanism, simple and quick manual adjustment method, supporting stepless adjustment of blade clearance

2. Standard Components:

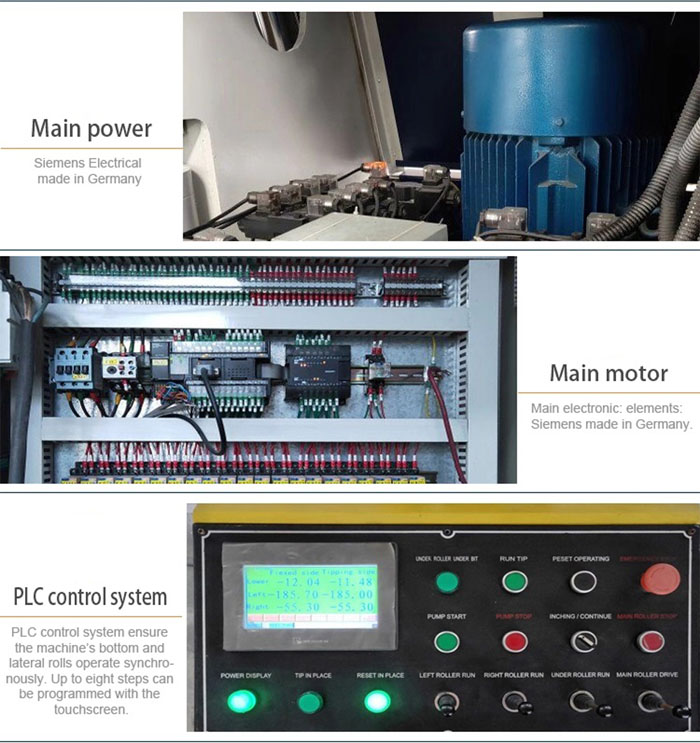

●OMRON PLC controller

●Germany Bosch Rexroth integrated hydraulic valve

●High pressure hose

●Germany Siemens main motor

●France Schneider electric

●Hydraulic and electric overload protection

●America Sunny oil pump

●Work roller made by 42CrMo steel

3. Safety Standard:

●Safety standard (2006/42/EC)

●Open electric cabinet to cut off power

●Movable console (safety grade 4)

●Machine metal safety fence, CE standards

●Safety relay monitors console, safety protection

4. OMRON PLC operating & control system

Main functions:

●TP765 color display

●Pre-set displacement value of each roller

●Set coordinate position

●Check top roller position

●Reset Drop-end

●Positive and negative rotation control of main roller

●Material presser rising/declining control

●Left and right rollers rising control

Four Roller Plate Rolling Machine Specification parameters:

|

Max. Roll Thickness (mm)

|

Max. Roll Width (mm)

|

Plate yield limit (MPa)

|

Rolling Speed (m/min)

|

Fully loaded with minimum boards Diameter (mm)

|

Top Roller Diameter

(mm)

|

Bottom Roller Diameter

(mm)

|

Lateral Roller Diameter

(mm)

|

Lateral Roller Movable Distance

(mm)

|

Lateral Roller Moving Speed

(m/min)

|

Motor Power

(kw)

|

|

25

|

2000

|

245

|

4

|

800

|

350

|

320

|

280

|

240

|

80

|

22

|

|

20

|

2500

|

245

|

4

|

640

|

350

|

320

|

280

|

240

|

80

|

30

|

|

30

|

2000

|

245

|

4

|

1000

|

400

|

360

|

300

|

240

|

80

|

37

|

|

25

|

2500

|

245

|

4

|

800

|

400

|

360

|

300

|

240

|

80

|

37

|

|

35

|

2000

|

245

|

4

|

1200

|

420

|

380

|

330

|

210

|

80

|

37

|

|

30

|

2500

|

245

|

4

|

1000

|

400

|

360

|

320

|

230

|

80

|

37

|

|

40

|

2000

|

245

|

4

|

1400

|

480

|

400

|

340

|

420

|

80

|

45

|

|

45

|

2000

|

245

|

4

|

1600

|

500

|

450

|

400

|

380

|

80

|

45

|

|

35

|

2500

|

245

|

4

|

1200

|

480

|

400

|

340

|

420

|

80

|

45

|

|

40

|

2500

|

245

|

4

|

1400

|

500

|

450

|

400

|

380

|

80

|

45

|

|

45

|

2500

|

245

|

4

|

1600

|

530

|

480

|

420

|

450

|

80

|

63

|

|

35

|

3000

|

245

|

4

|

1200

|

500

|

450

|

400

|

380

|

80

|

45

|

|

45

|

3000

|

245

|

4

|

1600

|

560

|

500

|

450

|

450

|

80

|

63

|

|

55

|

2500

|

245

|

4

|

2000

|

600

|

550

|

480

|

500

|

78

|

75

|

|

55

|

3000

|

245

|

4

|

2000

|

620

|

560

|

490

|

500

|

78

|

75

|

|

65

|

3000

|

245

|

4

|

2400

|

670

|

600

|

530

|

550

|

78

|

110

|

Standard/Optional Configuration List:

No

|

Accessory

|

Model / Manufacturer

|

Configuration

|

|

1

|

Controller

|

OMRON PLC Controller

|

Standard

|

|

2

|

Electric

|

Schneider- France / Travel switch & Limit switch

|

|

3

|

Main Motor

|

Siemens-Germany

|

|

4

|

Hydraulic System

|

Bosch Rexroth-Germany

|

|

5

|

Oil Pump

|

Sunny-USA

|

|

6

|

Sealing Ring

|

PARKER-USA/NKO-Japan

|

|

7

|

Oil Pipe Connector

|

High Pressure Hose

|

|

8

|

Machine Safety Fence

|

DURMACNC

|

|

9

|

Left and Right Material Supporting device

|

DURMACNC

|

Optional

|

|

10

|

Vertical Lift Top Support System

|

DURMACNC

|

|

11

|

Safety Standards

|

CE CSA NR-12 OSHA

|

|