This series of “HDE” fiber laser cutting

machines offers an unbeatable high production level and excellent cutting

quality for thin and medium thickness sheets. The maximum sheet thickness

depends on the chosen output power. The high energy efficiency of the fiber

laser ensures a significant reduction in energy consumption. The machines are

available with output power ranging from 1000 watts to 8000 watts.

Main Features:

Specifications:

|

Model

|

F4020HDE

(3015/6020 options)

|

|

Working

Area

|

4000mm*2000mm

|

|

Fiber

Laser Power

|

1000W/1500W/2000W/3000W/4000W/6000W/8000W/10000W/12000W

|

|

X

axis stroke

|

2000mm

|

|

Y

axis stroke

|

4000mm

|

|

Z

axis stroke

|

120mm

|

|

X/Y

position accuracy

|

±0.05mm/m

|

|

X/Y

Reposition Accuracy

|

±0.03mm

|

|

X/Y

axis Max Acceleration

|

1.2G

|

|

Max

Velocity of Movement

|

120m/min

|

|

Laser

Cutting Head

|

China

WSX .Germany Precitec.Highyag. Swiss Raytools.

|

|

Laser

cnc control

|

China Cypcut or PA.beckoff.

|

|

Servo

Motor

|

Japan or France Brand

|

|

Rack

and pinion

|

Taiwan

brand

|

|

Workbench

max load

|

900KG

|

|

Min

Cutting Kerf

|

0.12mm

|

|

Overall

Dimension

|

1150*3640mm*2100mm

|

|

Machine

Weight

|

Approx

16000KG

|

.

Figures:

Better Machine shell sheet steel and durable beams.

Laser built with the Best Aviation Grade Extruding Aluminum Machine gantry.

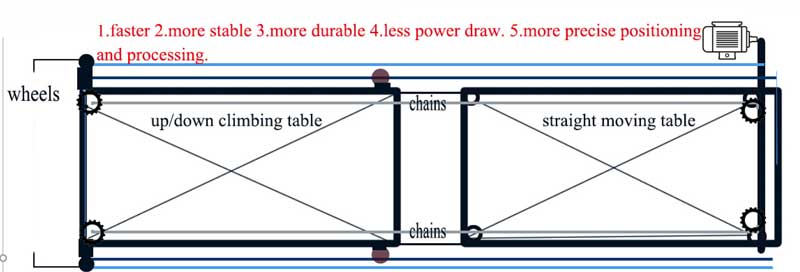

Shuttle Table fig.

High quality driving parts.

Some other Laser Cutting Machines for reference.

Fiber laser cutting machine advantages:

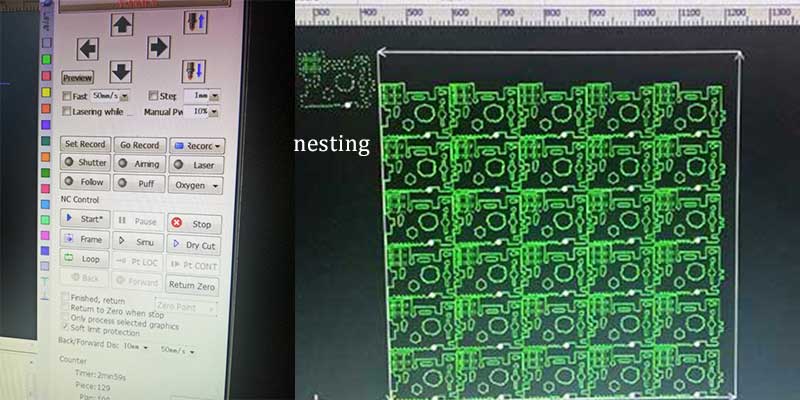

Fiber laseris a time saver and energy saver for metal fabrication and the main stream for now and the future .fiber lasers have become the true workhorse of metal fabrication,and they have never been more productive.

They cut nests at unprecedented speeds and produce finished parts with fine edge while power draw not so high .

Fiber laser cutting machine offers an unbeatable high production level and excellent cutting quality forthin and medium thickness sheets. The maximum sheet thickness depends on the chosen output power.

The high energy efficiency of the fiber laser ensures a significant reduction in energy consumption. The machines are available with output power ranging from 1000 watts to 12000 watts.

Laser Machine has Wide Application in Metal

Fabrication

Laser cutting, laser welding, laser

marking or laser drilling – lasers are used in a wide variety of processes in

many different industrial sectors to optimize manufacturing processes and to

ensure the high quality of components.

Why shuttle table is needed in Laser cutting machine?

Cutting is one of the 6 progresses of laser processing cycle,while shuttle table bring boost in productivity, suited for

high-throughput environments.when one table is cutting ,the finished parts in other table can be picked up.

What is concerned for good cut edge quality?

A high quality laser cut depends on many factors ,laser

machine itself ,assist gases,nozzle option and status,material,table slats cleaning,job shop environment ,operators

skills...Attaining a burr-free cut is about setting up the laser beam

parameters and gas flow dynamics to work together to ensure the right amount of

molten metal evacuates the kerf at the right time and in the right way.

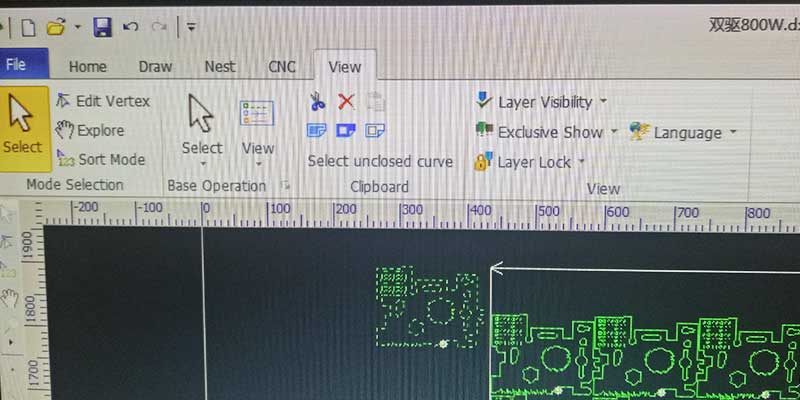

About CypCut Laser

Cutting Control System from User Manual

Version: V6.3.711

Thank you

for using CypCut laser cutting control system.

CypCut laser

cutting control system (CypCut for short) is a set of system software designed

for plane laser cutting, including laser cutting process, common layout

function and laser processing control, most of its functions are applied in

graphics processing, parameter settings, custom cutting process editing,

layout, path layer planning, simulation and cutting process control.

CypCut

software can realize process control only if used with Dog and Control Card.

CypCut will

enter DEMO mode while running on a computer without Dog, so that you can get

all other functions except process control for

normal use.Therefore,

CypCut can be installed in a separate notebook for the design before

processing.

About Baisheng

Laser

We are highly

preferred laser cutting machine manufacturer since 2004.Up to 5 manufacturing plants in Guangzhou and Foshan city in Canton province.

we build full series laser cutting machines covering flat sheet and tube and pipe cutting .