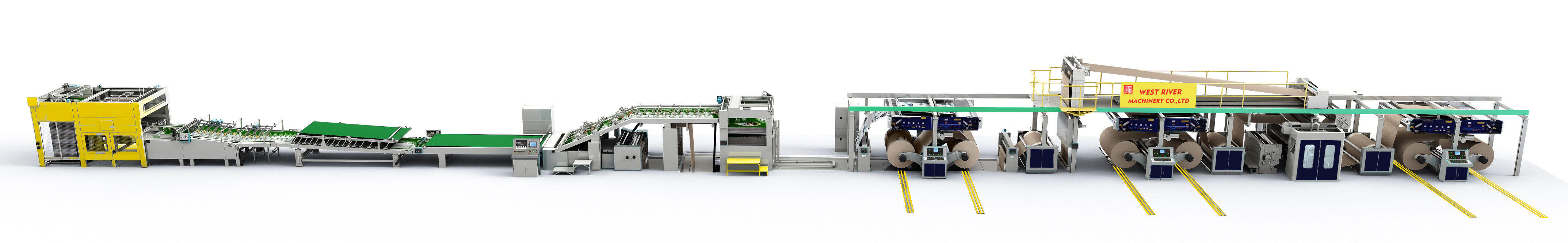

Fully Automatic Cardboard Laminaited Machine with Flip Flop

The fully automatic laminator machine adopted with motion control system and servo correction system perfect combination, using multiple sets of photoelectric sensor at the end of the paper the relative position, control top paper on both sides of the servo motor independent drive compensation action, top paper and bottom paper precise positioning. Servo laminating machine has the advantages of simple operation, only need to input the size of paper can be completed automatically adjust the machine.

Auto (Flip Flop) Pile Turner and Stacker Machine is the special accessory products for sheet to sheet laminating machines and can be connected with any of manufacturer’s laminating machine. This integrative equipment can auto make the laminated papers to piles according to specified number. With collecting, piling, intermittent turning and stacking functions, realize collected paper front and backside placed stacking, effectively prevent laminated paper curving and manpower-saving for labor collecting strength.

|

Max sheet size

|

1450×1450mm

|

1650×1650mm

|

|

Min sheet size

|

400×400mm

|

400×400mm

|

|

Top paper thickness

|

120-500g

|

120-500g

|

|

Precision for front and back

|

±1mm

|

±1mm

|

|

Air Consumption

|

0.2m3/min

|

0.2m3/min

|

|

Overall

|

15.5×2.4×2.4M

|

15.7×2.6×2.4M

|

|

Machine power

|

22KW

|

25KW

|

|

Bottom paper

|

A、B、C、E、F、G Corrugated paper

Four Layers Corrugated paper: AB/BB/BC/EE

Cardboard paper is above the 300GSM

|

Features:

Product Show

Inline laminator with corrugated line for option

FAQs

1Q: Are you the manufacturer?

A: Yes, we are the professional manufacturer combined with WEST RIVER, KL&Japan Shinko, Nantai & Japan Asahi, Jiayi, Guanwei, Jinshun brand machines.

2Q: Where are your factory located in ?

A: Our factories located in Shanghai, Guangzhou, Foshan, Zhaoqing Cities in China

3Q: How to choose the corrugated machine ?

A: According to your market requirement for the cardboard thickness, your target requirement, raw material size, we will give you the best choice of the corrugated machine.

4Q: What can you do for me?

A: Usually the customer need to choose the corrugated machine, flexo printer, die cutter and other converter machine separately by different supplier, but we will give you the whole plan design solution from A to Z, what you need to do is just tell us your target, then you will get the most suitable proposal from us.

5Q: How to control machine quality ?

A: All material are environmental protection,non-pollution, We have professional technicists to supervising to production, Our professional department to examine about every production process

6Q:What can you do if the machine face problem?

A: We provide the machine remote service system, and the warranty period is 1 year. If the broken parts can't repair, we can send the new parts to replace the broken parts for free, but you need to pay the freight. After warranty period, we will charge for the maintanance, and we supply the technical support for the whole life of the equipment.