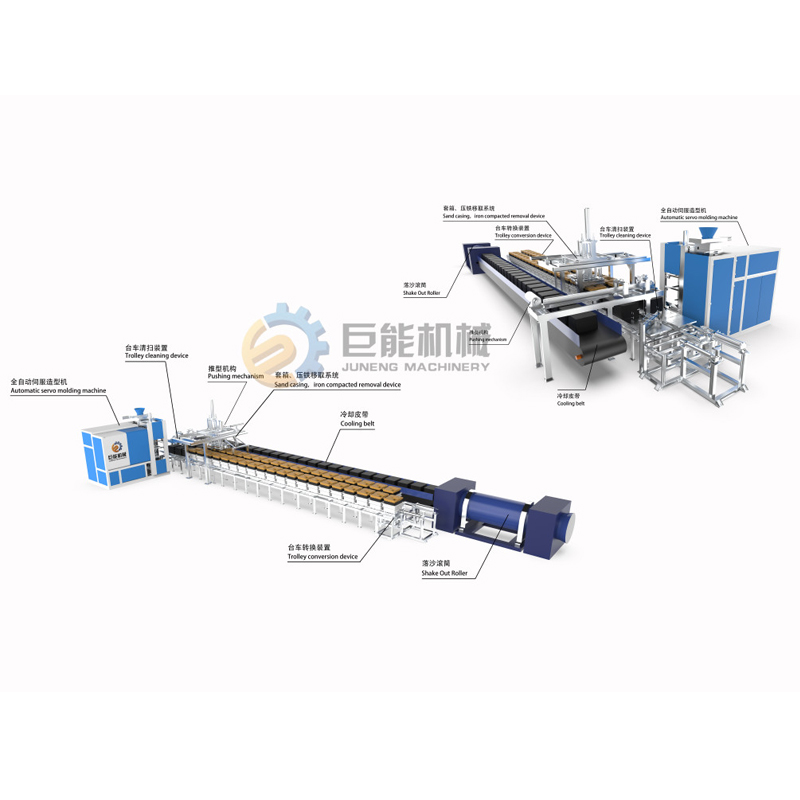

Molding machine,casting line,cooling line,transport system,electronic control,hydraulic pressure and pneumatic system make up this Automatic Molding Line.This is the international advanced horizontal parting and removable flask shoot and squeeze molding line.

JN5161 series horizontal parting flaskless moulding line has following characteristics :compact appearance, compact structure, safety performance is high, easy to operate, cover an area of an area small, less pollution, low noise, and the use of casting a wide range, can produce auto parts, such as cylinder head, flywheel shell, brake pliers, etc.; Also applies to pipe classes, valve class, the axial, cover parts production, such as direct, tee, elbow, pipe clamp, etc.

MAIN TECH.SPEC:

|

Model

|

JN5161

|

|

Sand size(mm)long(L)×wdith(B)

|

510×610

|

|

Modeling method

|

Start blowing sand+squeeze

|

|

Modeling speed (excluding core length)

|

30 seconds/floor

|

|

Compressed air consumptio

|

1.2m³

|

|

System air pressure

|

0.75Mpa

|

|

Using voltage

|

AC220V orAC380V

|

|

Using motor power

|

18kw

|

|

Hydraulic system,maximum pressure

|

6Mpa

|

|

Sand type weight

|

180kg

|

The Juneng green-sand molding process brings highly innovative features that improve upon traditional molding process – highest quality castings, high productivity – lowest cost of ownership.