Heating Vacuum Chamber Thermal Shock Control Cycling Test Chambers

|

|

|

Model

|

RTS-50

|

RTS-80

|

RTS-100

|

RTS-150

|

RTS-200

|

RTS-300

|

|

System

|

Balanced temperature & humidity control system

|

|

High temp. chamber

|

60°C~200°C

|

|

Preheating time

|

60°C~200° about 20minutes

|

|

Low temp. chamber

|

A: -55℃~10℃, B: -70℃~10℃, C: -80℃~10℃

|

|

Precooling time

|

+20℃~-55℃ 60 minutes, +20℃~-75℃ 75 minutes, +20℃~-80℃ 90 minutes

|

|

Test chamber

|

A: -40℃~150℃, B: -55℃~150℃, C: -65℃~150℃

|

|

Recovery time

|

heat exposure 30 minutes, low exposure 30 minutes,

|

|

Transfer time

|

Within 10 seconds

|

|

Temp. flucturation

|

±1.0℃

|

|

Temp. deviation

|

≤±2.0℃

|

|

|

W40

|

W50

|

W55

|

W68

|

W68

|

W80

|

|

H40

|

H40

|

H45

|

H45

|

H50

|

H50

|

|

D32

|

D40

|

D40

|

D50

|

D60

|

D75

|

|

Test weight (KG)

|

3.5kg

|

5kg

|

5kg

|

5kg

|

10kg

|

12kg

|

|

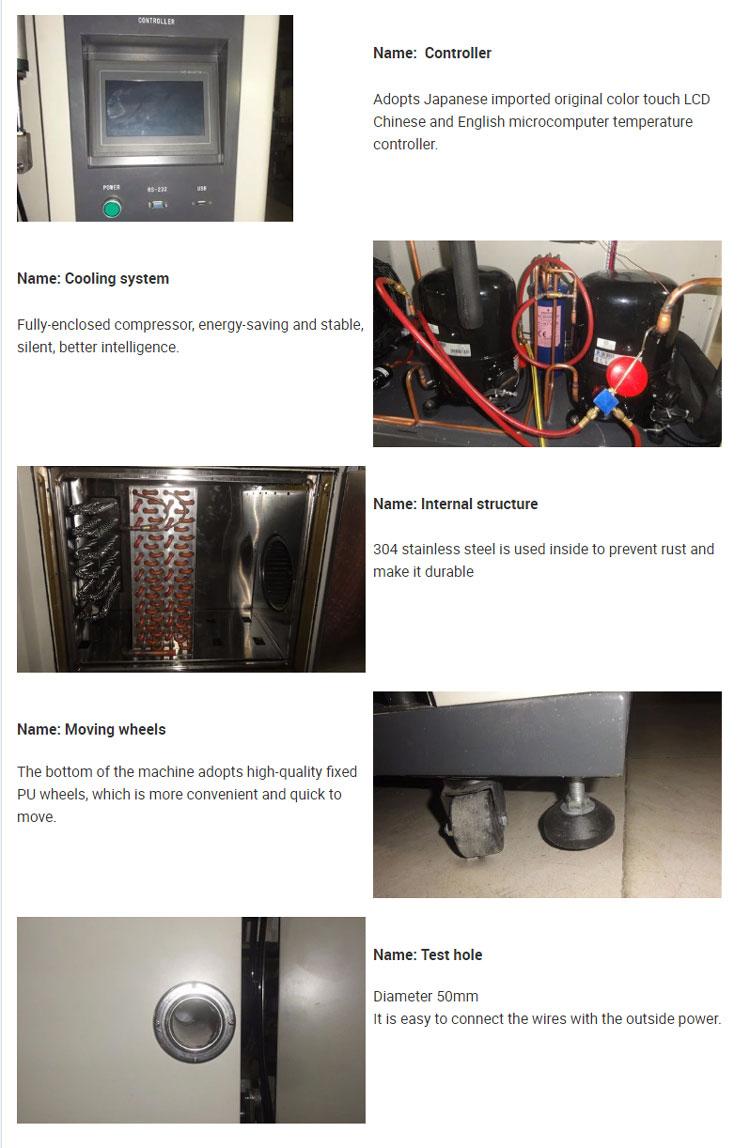

Interior material

|

Stainless steel 304

|

|

Exterior material

|

Backed paiting steel or stainless steel(SUS304)

|

|

Insulation material

|

Rigid polyruethane foam +glass fibre

|

|

Cooling system

|

1. Air cooled (Water cooled type is option)

2. Singl section/cascade type, hermetic/semitight compressor,CFC free refrigerant

|

|

Controller

|

Color LCD screen in English/Chinese, programing,communicating function

|

|

Safety devices

|

No welding wire switch, compressor overheating and over current protection, over temperature protection, blower overload protection, dry heating machine protector,low water protection, fault warning system.

|

|

Standard accessories

|

one test hole(diam5cm), two sets of test racks, four moving wheels, 2 meters of power cord, communication interface.

|

|

Power

|

AC380V±10% 50HZ 3 phase 4 wires+ground wires

|

Programmable Thermal Shock Test Chamber is used to test the bearing extent of the material structures and composite material in an instant and continuous high temperature and extremely low temperature environment, that is in the shortest time to test its thermal expansion and contraction caused by chemical change or physical harm, which is widely used in metal, plastic, rubber, electronics and other materials and it can be used as an important reference for improving product quality.

1) Three chamber structures, high temperature chamber, low temperature chamber and test chamber, control automatically, stay and switch time adjustable.

2) Perfect protection alarm functions: short-circuits, Leakage, over temperature of work chamber; compressor over pressure, over load, short water.

3) LCD English microcomputer temperature controller, with high memory capacity, can save 100 programs, each cycle max time 999hrs. Using touch-control graph control as operation interface, easy to operate.

4) Have safety protection equipment and power failure memory.