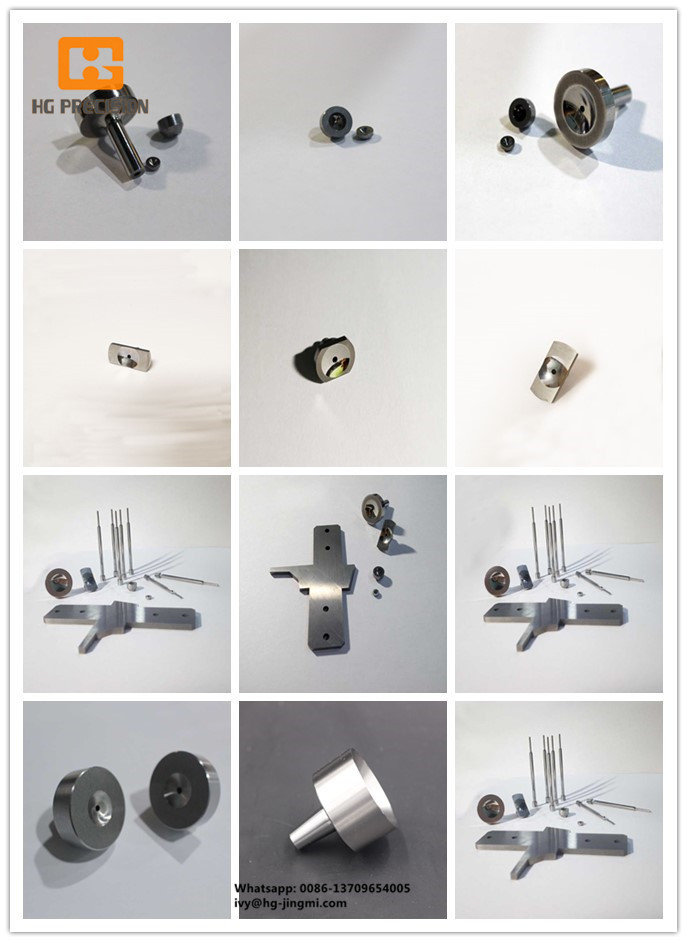

High Accuracy Sprue Bushing For Japanese

Market

Minimum Order Quantity: 1pc

Material: HAP10 or HAP40

Hardness: HRC48-52

Standard: HASCO, MITSUMI, JIS, DME, DIN

Heat treatment: vacuumed

Application: plastic injection mould

Accuracy: 0.003mm

Type: non-standard, per customer customzied

Standard: HASCO, MITSUMI, JIS, DME, DIN,

FIBRO

Surface Polish: Mirror Polishing

Package: Customized package for sprue

bushing

Manufacture Process: EMD mirror spark

machinery and grinding, polishing, heat treatment

Manufacture lead time: 4-6days for sample,

6-14days for mass production

Quality Control: 100% full check

Shipment: DHL, TNT, UPS, FEDEX, EMS, OCS or

other special express lines

Our advantage:

1.reliable quality

2. Competitive price

3. High precision, high quality, tight tolerance

4. Sustainable improve

5.Defect-free products

6. On-time delivery

7. Customer satisfaction

8. Excellent after-sales service.

We are the sprue bushing parts process

designer, manufacture, exporter, over 10years import experience to Japan, USA,

Germany.

Welcome OEM/ODM Orders!

Sprue bush can also be described as a flow

path component that allows molten plastic material to be injected from the

nozzle of the injection molding machine into the interior of the mold.The

bolt-type nozzle is a nozzle that is fixed by two bolts and is fixed by bolts

to prevent the nozzle from falling off due to the injection pressure.

The sprue bushing is often used as the grab

point in robotic removal of parts, sprues and runners. This requires that the

sprue be rigid enough to resist the pressure of the robot fingers as well as

the extraction forces. With conventional steel sprues this measure is most

often met by added cooling time to the mold cycle. HG Precision will again

reduce the sprue cool time, without any other changes to the mold. Use of this

product will yield more rigid sprues with reduced cool times set on the molding

machine timer.

The sprue bushing fits into the locating

ring. The end is connected to either an opening in the main runner or directly

to the mold cavity, depending on the setup. The sprue bushing directs the

plastic through the runners, past the gate, and into the mold cavity, or

directly into the cavity.Before you place the sprue bushing, identify the mold

base. The two placement methods are Linear and From Runner Sketch. The Linear

option positions the sprue bushing relative to two linear edges. The From Runner

Sketch option positions the sprue bushing based on the end point or a point on

the runner sketch geometry.