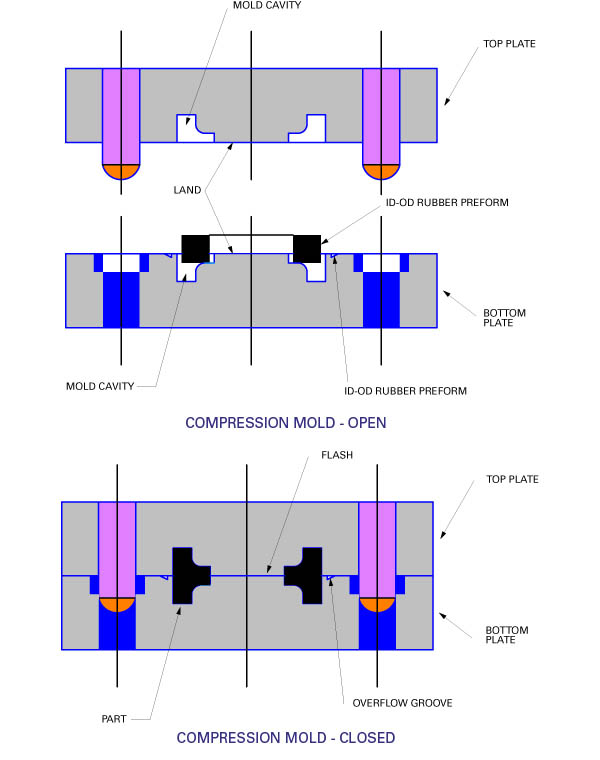

Compression molding is a process that involves taking a rubber compound or mixed raw material and creating "pre-forms" in the basic shape of the end product.

Detailed Descriptions:

|

Rubber Mould Material

|

50 steel, P20 steel, etc.

|

|

Size

|

According to your drawing

|

|

Mold structure

|

Compression Mold, according to product's structure

|

|

Mould Base

|

LKM / HASCO /DME, etc

|

|

Mould Core

|

718H,S136, NAK80, P20 , H13, YK30, etc

|

|

Treatment

|

Polish / Semi-Matt / High Gross / Texture

|

|

File Format

|

.stp, .prt, .igs, .sldprt, .stl, .dwg, .pdf

|

|

Cavity

|

Single / Multi

|

|

Precision Machining

|

CNC / Cutting / Carved / EDM/Milling/Threading/Drilling, etc

|

|

RoHs & REACH

|

RoHs & REACH directive compliant green products

|

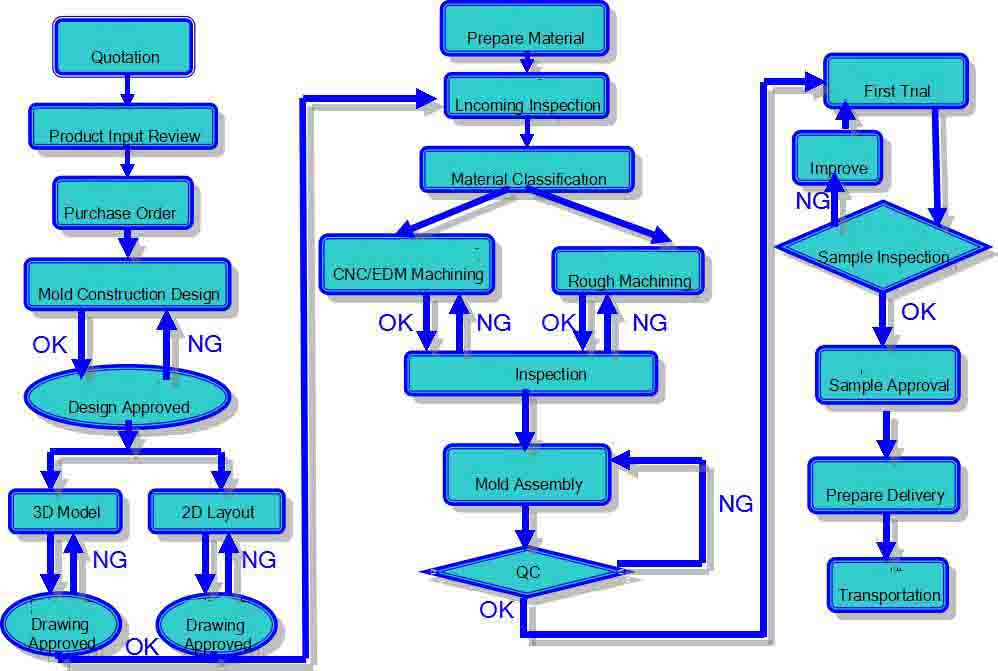

Rubber mould making:

Procedure:

Other Moulds: