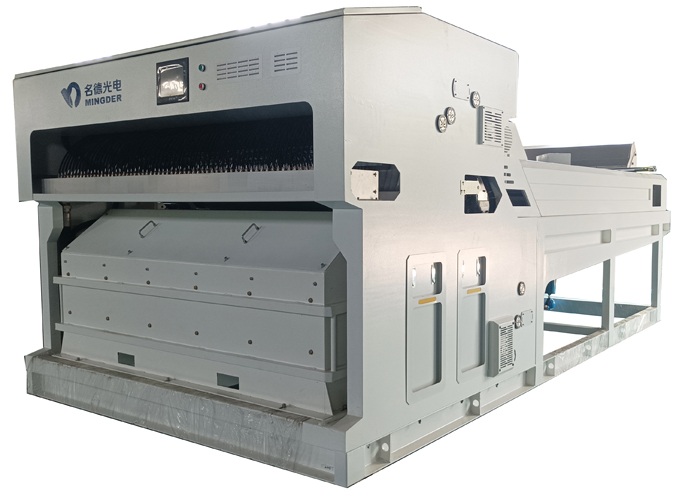

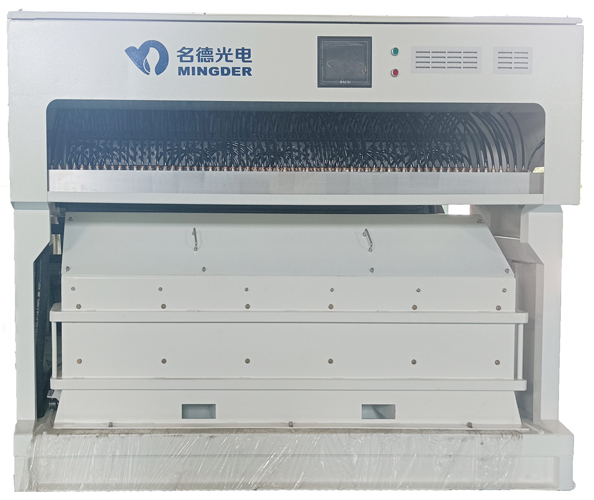

Heavy duty Ore color sorter

The new generation of Mingde Heavy-duty ore separator breaks through the existing ore separation technology, adopts heavy fast track design and has strong integration technology, which can sort large ore particles with high yield.

Using the advanced AI photoelectric sorting new technology, accurately identify the subtle differences on the surface of the ore, intelligently discard the waste tailings and get the concentrate.

Technical characteristics

1, Large range of materials are able to be sorted, sorting materials size up to 3 ~ 8 cm, to avoid repeated crushing by the using color sorting machine,reduce the crushing,and reduce the waste of resources

2,Adopt self-developed special software system for large particle size and closed machine structure, the main internal components are imported, can adapt to the industrial and mining industry with high dust, high pollution, high corrosion and other harsh environments , a wider range of applications, longer life

3, High precision full color line array CCD sensor technology, can detect 0.02mm2 subtle color difference, according to the different characteristics of the ore, using different processing methods, to ensure the accurate identification of ore and other sorted materials

4, The first to launch special models of large particle size intelligent ore sorting machine , fast track identification system, processing capacity is huge, the yield has broken through 50 ~ 80 tons / hour, far ahead of similar domestic manufacturers. In order to reduce the inertia of ore rolling, the body specially designed, reinforced and lengthened. Lower blowing separation, with small amount of air consumption, and small carryover of tailings.

5, the vibrating feeding part and the main body of the equipment adopt the split structure to avoid the influence of vibration on the main machine during the feeding process and make the operation of the equipment more stable

6, the first manufacturer to develop a large particle size sorting , to meet the sorting requirements of materials with larger particle size

Product parameters

|

Model

|

MS-TD6

|

Power KW

|

10

|

|

Yield

|

45~80(3cm<d≤8cm)

|

Air Pressure

|

0.5~1.0MPA

|

|

150~200(8cm<d≤15cm)

|

|

Color sorting accuracy(%)

|

≥99.9

|

Air Consumption(L/min)

|

≤16000

|

|

Optimized carryover

|

≥50:1

|

Total Weigh kgs

|

6000

|

|

Power Supply

|

AC220V 50HZ

|

Dimension

(LXWXH: mm)

|

6790x2502x2190

|

Note: 1, d: means the diameter of the sorted material particles

2, the above performance is based on the example of 5% calcite, the specific indicators vary according to the material and the amount of impurities

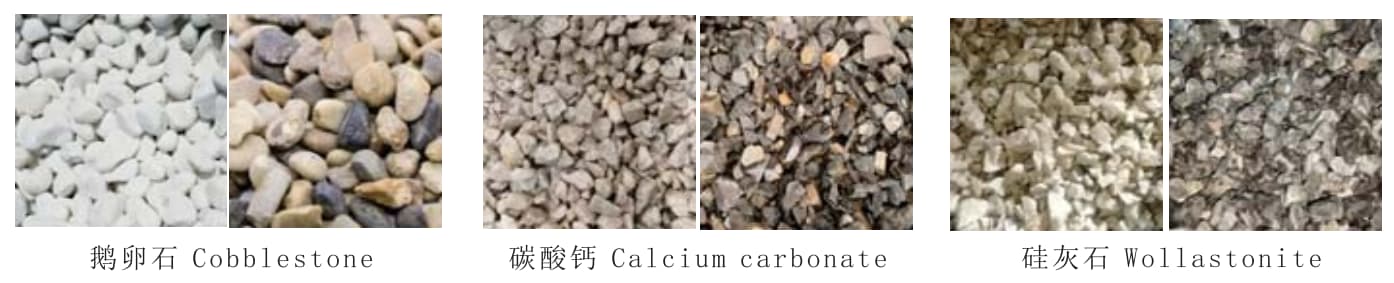

Color sorting case: pebbles Calcium Carbonate Wollastonite