Specification of conductive graphite powder:

|

Part No.

|

Particle

|

Purity

(%)

|

SSA

(m2/g)

|

Bulk density

(g/cm3)

|

Density

(g/cm3)

|

Crystal

|

Color

|

|

TP06GP-40N

|

40nm

|

99.9

|

15

|

1.2

|

2.25

|

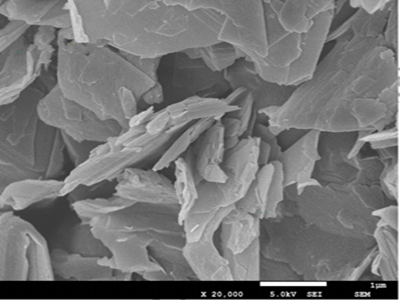

Flake

|

black

|

Note: We can supply different size products of conductive graphite powder according to client's requirements.

Graphite powder with melting point of 3850 ± 50 ℃, boiling point of 4250 ℃, even after ultra-high temperature electric arc burning, weight loss is very small. Graphite also with thermal small expansion coefficient and at 2000 ℃ temperature strengthen increase which is double than before. Graphite is available to use in electrical conductivity and thermal conductivity industrial like electronic industry and thermal insulation material.

Application of conductive graphite powder:

1. Graphite with excellent electrical conductivity, thermal conductivity: Graphite’s conductivity is higher than the general non-metallic minerals a hundred times. Graphite’s thermal conductivity is much better than steel, iron, lead, and other metal element materials. With the great properties, graphite powder is widely used as electrode, the positive brushes, carbon rod, carbon tubes, mercury positive converter, graphite gaskets, phone parts, television picture tube coatings in the electrical industry as a manufacturer.

2. Graphite powder is also a good lubricating additive powder. The performance of lubrication depends on the size of the graphite flake graphite, the larger of the flake the smaller of the coefficient of friction and lead to the better lubrication.

3. Graphite powder is stable powder at room temperature, graphite is acid, alkali and corrosion resistance and also resistance of organic solvents.

SEM & XRD of conductive graphite powder:

Storage conditions:

conductive graphite powder should be sealed and stored in a dry and cool environment. It should not be exposed to the air for a long time, to prevent agglomeration due to moisture, affecting the dispersion performance and use effect, and should avoid heavy pressure, do not contact with oxidant, and transport according to ordinary goods.