Specification of copper nanopowder:

|

Part No.

|

Particle

|

Purity

(%)

|

SSA

(m2/g)

|

Bulk density

(g/cm3)

|

Density

(g/cm3)

|

Crystal

|

Color

|

|

MP29-50N

|

50nm

|

>99.9

|

15

|

0.2

|

8.9

|

Spherical

|

Black

|

MP29-100N

|

100nm

|

>99.9

|

12

|

0.8

|

8.9

|

Spherical

|

Dark Red

|

MP29-1U

|

1um

|

>99.9

|

3.8

|

1.35

|

8.9

|

Spherical

|

Red

|

MP29-5U

|

5um

|

>99.9

|

3.2

|

1.5

|

8.9

|

Near Spherical

|

Red

|

Note: We can supply different size products of ultrafine copper powder according to client's requirements.

High purity, uniform particle size distribution, easy to disperse.

Application ofcopper nanopowder:

1. Used as a production of microelectronic devices, used in the manufacture of terminals for multilayer ceramic capacitors, and also as a catalyst in the reaction process of carbon dioxide and hydrogen synthesis of methanol. Can also be used as a petroleum lubricant industry.

2. Metal nano-lubricating additive: Adding 0.1~0.6% to the lubricating oil and grease, the self-lubricating and self-repairing film is formed on the surface of the friction surface during the friction process, which significantly improves the anti-wear and anti-friction performance of the friction pair.

3. Metallic and non-metallic surface conductive coating treatment: Nano-aluminum, copper, nickel powder has a highly activated surface, and under anaerobic conditions, the coating can be applied at a temperature lower than the melting point of the powder. This technology can be applied to the production of microelectronic devices.

4. High-efficiency catalyst: Copper and its alloy nano-powder are used as catalysts, with high efficiency and strong selectivity, and can be used as catalysts in the reaction process of carbon dioxide and hydrogen synthesis of methanol.

Conductive paste: used for terminal and internal electrodes of MLCC to miniaturize microelectronic devices. It can replace the precious metal powder to prepare the electronic slurry with superior performance, which can greatly reduce the cost and optimize the microelectronic process.

5. Raw materials for bulk metal nanomaterials: Preparation of bulk copper metal nanocomposite structural materials by inert gas protection powder metallurgy sintering.

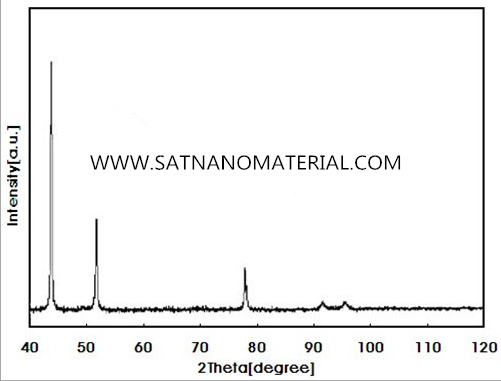

SEM & XRD of copper nanopowder:

Storage conditions:

copper nanopowder should be sealed and stored in a dry and cool environment. It should not be exposed to the air for a long time, to prevent agglomeration due to moisture, affecting the dispersion performance and use effect, and should avoid heavy pressure, do not contact with oxidant, and transport according to ordinary goods.