Specification of nickel particle:

|

Part No.

|

Particle

|

Purity

(%)

|

SSA

(m2/g)

|

Bulk density

(g/cm3)

|

Density

(g/cm3)

|

Crystal

|

Color

|

|

MP28-40N

|

40nm

|

99.9

|

13

|

0.74

|

8.9

|

Spherical

|

black

|

MP28-100N

|

100nm

|

99.9

|

10

|

1.38

|

8.9

|

Spherical

|

black

|

MP28-1U

|

1-3um

|

99.9

|

4.1

|

1.85

|

8.9

|

Spherical

|

black

|

Note: We can supply different size products of nickel particle according to client's requirements.

1. High purity, nickel content is not less than 99.9%;

2. The content of carbon, phosphorus, oxygen and other elements is low;

3. The granularity is controllable and the loose ratio is controllable;

4. The powder has good compression performance and good fluidity.

Application of nickel particle:

1. The magnetic fluid produced by magnetic fluid with iron, cobalt, nickel and its alloy powder has excellent performance and can be widely used in the fields of sealing shock absorption, medical equipment, sound adjustment, light display and the like;

2. High-efficiency catalyst: Due to its large surface area and high activity, nano-nickel powder has a strong catalytic effect and can be used for organic hydrogenation reaction, automobile exhaust gas treatment, etc.

3. Efficient combustion-supporting agent: Adding nano-nickel powder to the solid fuel propellant of the rocket can greatly improve the burning speed, combustion heat and combustion stability of the fuel:

4. Conductive paste: Electronic paste is widely used in wiring, packaging, and connection in the microelectronics industry, and plays an important role in miniaturization of microelectronic devices. The electronic slurry made of nickel, copper, aluminum and silver nano powder has superior performance, which is beneficial to further miniaturization of the circuit;

5. High-performance electrode material: With nano-nickel powder and appropriate process, it can produce an electrode with a large surface area, which can greatly improve the discharge efficiency;

6. Activated Sintering Additives: Nano-powders have a high energy state due to their large surface area and surface atomic proportions. They have strong sintering ability at lower temperatures and are an effective sintering additive. Lowering the sintering temperature of powder metallurgy products and high temperature ceramic products;

7. Dependent and non-metallic surface conductive coating treatment: Since nano aluminum, copper, and nickel have a highly activated surface, the coating can be applied at a temperature lower than the melting point of the powder under anaerobic conditions. This technology can be applied to the production of microelectronic devices.

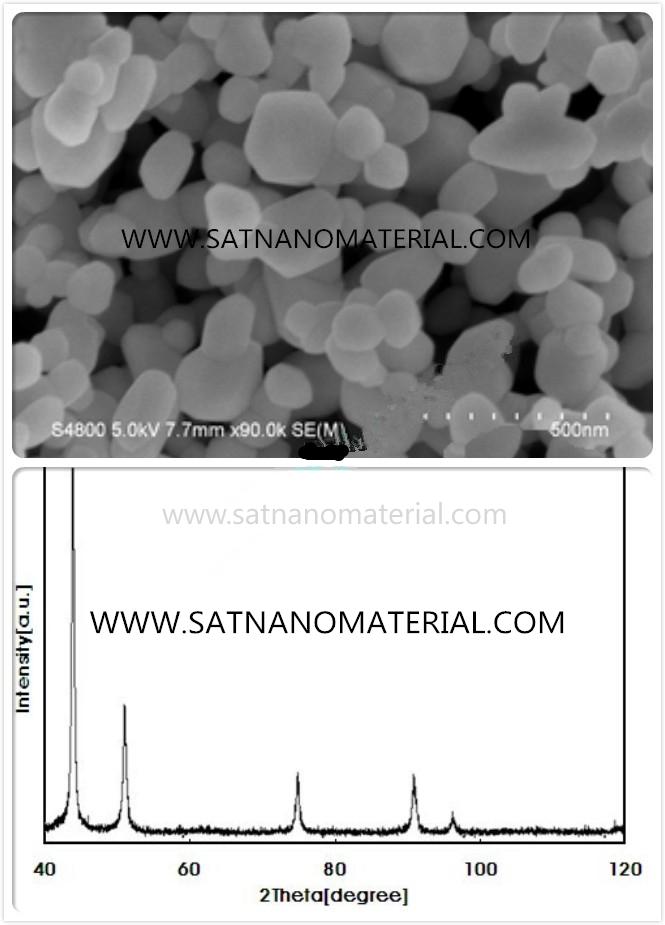

SEM & XRD of nickel particle:

Storage conditions:

nickel particle should be sealed and stored in a dry and cool environment. It should not be exposed to the air for a long time, to prevent agglomeration due to moisture, affecting the dispersion performance and use effect, and should avoid heavy pressure, do not contact with oxidant, and transport according to ordinary goods.