Specification of zirconium carbide micron powder:

|

Part No.

|

Particle

|

Purity

(%)

|

SSA

(m2/g)

|

Bulk density

(g/cm3)

|

Density

(g/cm3)

|

Crystal

|

Color

|

|

CP4006-50N

|

30-50nm

|

99.9

|

74

|

0.19

|

15.5

|

cubic

|

black

|

CP4006-100N

|

80-100nm

|

99.9

|

50

|

1.5

|

15.5

|

cubic

|

black

|

CP4006-1U

|

1-3um

|

99.9

|

8

|

3.4

|

15.5

|

cubic

|

black

|

Note: We can supply different size products of zirconium carbide mircon powder according to client's requirements.

zirconium carbide micron powder has high purity, small particle size, uniform distribution, large specific surface area, high surface activity, low bulk density, high temperature resistance, oxidation resistance, high strength, high hardness, good toughness and good thermal conductivity. Zirconium carbide is an important high-temperature structural material with high melting point, high strength and corrosion resistance, and has the characteristics of efficiently absorbing visible light, reflecting infrared rays and storing energy.

Application of zirconium carbide micron powder:

1.New insulation and temperature-regulating textiles: Zirconium carbide has the characteristics of efficiently absorbing visible light and reflecting infrared rays. Zirconium carbide has ideal heat absorption and heat storage characteristics. The product can be used in new insulation and temperature control textiles.

2.High temperature resistant coating: The melting point of nano ZrC is 3540 °C. Zirconium carbide ceramics have good mechanical properties, especially in the harsh environment of high temperature resistance, and have high high temperature resistance. It is one of the indispensable materials in the field of aerospace.

3.Cemented Carbide: Zirconium carbide is an important high-temperature structural material with high melting point, high strength and corrosion resistance. Its excellent characteristics make it have a large application space on cemented carbide. The strength and corrosion resistance of cemented carbide with nano ZrC added are greatly improved.

4.Metal coating material: The low-density loose zirconia coating has good thermal stress resistance and insulation properties and can be used as an insulating material; the high-density dense zirconia coating has good penetration resistance and can be used as a protective coating.

5.Nuclear industry: Nano ZrC has high temperature strength, high hardness, small thermal neutron absorption cross section and good radiation resistance. It is used as a new material for coating nuclear fuel particles.

6.Abrasives: Nano ZrC has a Mohs hardness of 8-9 and good thermal conductivity. It is a good material for abrasives.

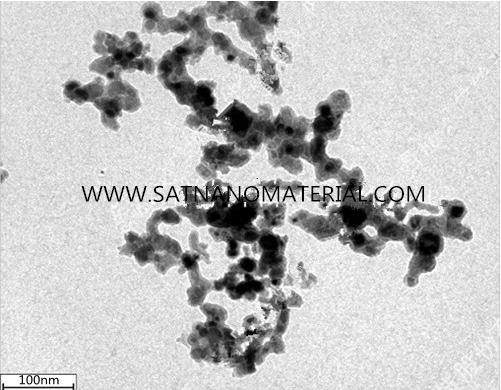

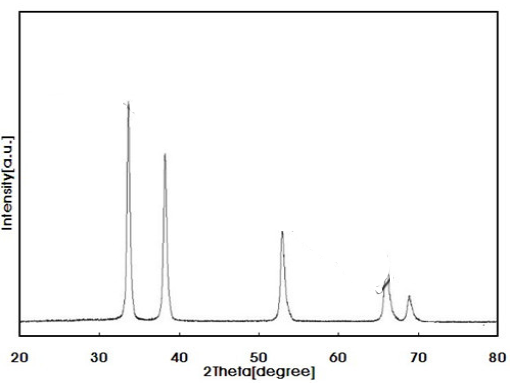

SEM & XRD of zirconium carbide micron powder:

Storage conditions:

zirconium carbide micron powder should be sealed and stored in a dry and cool environment. It should not be exposed to the air for a long time, to prevent agglomeration due to moisture, affecting the dispersion performance and use effect, and should avoid heavy pressure, do not contact with oxidant, and transport according to ordinary goods.