NICHIA UVC LED 280nm NCSU334A is specially used for sterilization and disinfection. NICHIA will push out a new product UVC-LED 280nm in April, 2019. Welcome to purchase the samples for testing.

Specifications of High Power NCSU334A 280nm UV LED for Disinfection:

1.Absolute Maximum Ratings of Best 280nm UVC UV Light

|

Item

|

Symbol

|

Absolute maximum rating

|

Unit

|

|

Forward current

|

IF

|

500

|

mA

|

|

Pulse forward current

|

IFP

|

600

|

mA

|

|

Allowable reverse current

|

IR

|

85

|

mA

|

|

Power dissipation

|

PD

|

3.16

|

W

|

|

Operating temperature

|

Topr

|

-10~85

|

℃

|

|

Storage temperature

|

Tstq

|

-40~100

|

℃

|

|

Junction temperature

|

TJ

|

110

|

℃

|

* Absolution Maximum Ratings at Ts=25℃

* TFP conditions with pulse width ≤10 ms and duty cycle ≤ 10%

2.Initial Electrical / Optical Characteristics of High power 280nm UVC UV Light

|

Item

|

Symbol

|

Condition

|

Typ

|

Max

|

Unit

|

|

Forward voltage

|

VF

|

IF=350mA

|

5.2

|

-

|

V

|

|

Radiant flux

|

Φe

|

IF=350mA

|

55

|

-

|

mW

|

|

Peak Wavelength

|

λp

|

IF=350mA

|

280

|

-

|

nm

|

|

Spectrum half width

|

△λ

|

IF=350mA

|

10.0

|

-

|

nm

|

|

Thermal resistance

|

RθJS

|

-

|

8.4

|

9.9

|

℃/W

|

|

RθJc_real

|

-

|

4.3

|

4.6

|

|

RθJc_el

|

-

|

4.1

|

4.4

|

* Characteristics at Ts=25℃.

* Radiant flux value as per CIE 127:2007 standard.

* RθJS is the thermal resistance from the junction to the Ts measurement point.

* Thermal Resistance values (RθJc_real) determined by considering the energy conversion efficiency (ηe=3%). Refer to JESD51.

* The thermal resistance between value (RθJc) is used to perform logical analysis (e.g. computer-based thermal analysis simulation) and represents a thermal resistance between the die to the Tc measurement point (PCB used : Aluminum PCB t = 1.5mm, Insulating layer t =0.12mm).

* For more details on thermal resistance, see CAUTIONS, (6) thermal management.

* It is recommended to operate the LEDs at a current greater than 10% of the sorting current to stabilize the LED characteristics.

RANKS of Soldering NVSU334A 280nm UV LED for Sterilization :

|

Item

|

Rank

|

Min

|

Max

|

Unit

|

|

Forward voltage

|

-

|

4.5

|

6.0

|

V

|

|

Radiant flux

|

P14

|

54.4

|

76.8

|

mW

|

|

P13

|

38.4

|

54.4

|

|

Peak wavelength

|

U280

|

275

|

285

|

nm

|

* Ranking at Ts=25℃

* Forward voltage tolerance : ±0.09V

* Radiant flux tolerance : ±6.5%

* Peak wavelength tolerance : ±3nm

* LEDs from the above ranks will be shipped. The rank combination ratio per shipment will be decided NICHIA.

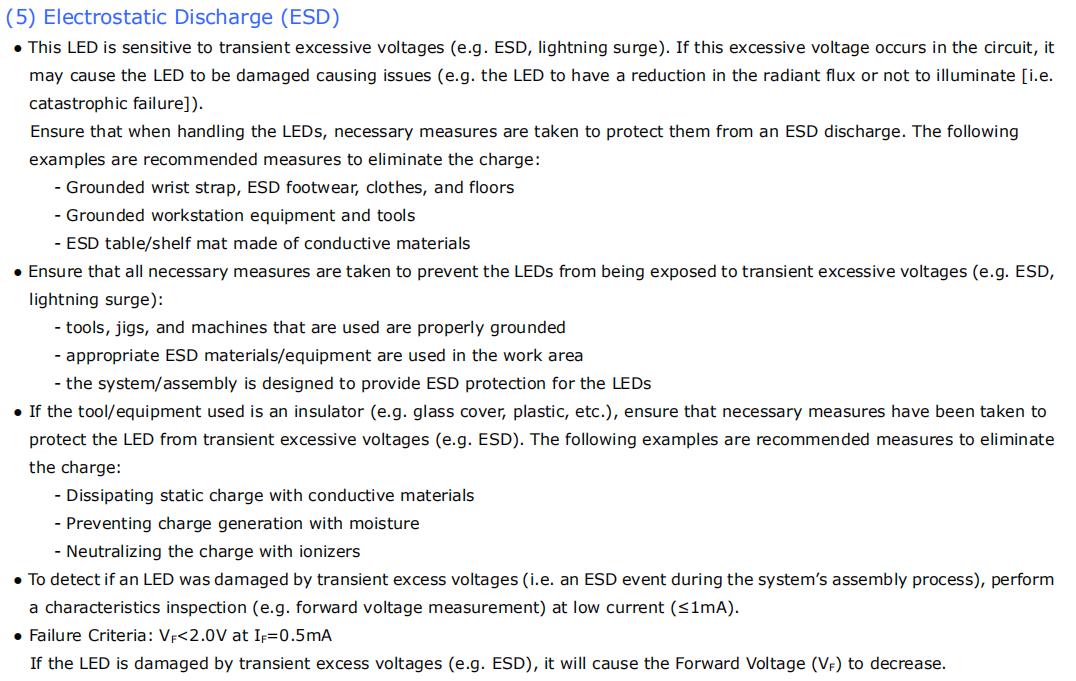

Outline Dimensions of Installing NCSU334A 280nm UV LED for UV Flashlight :

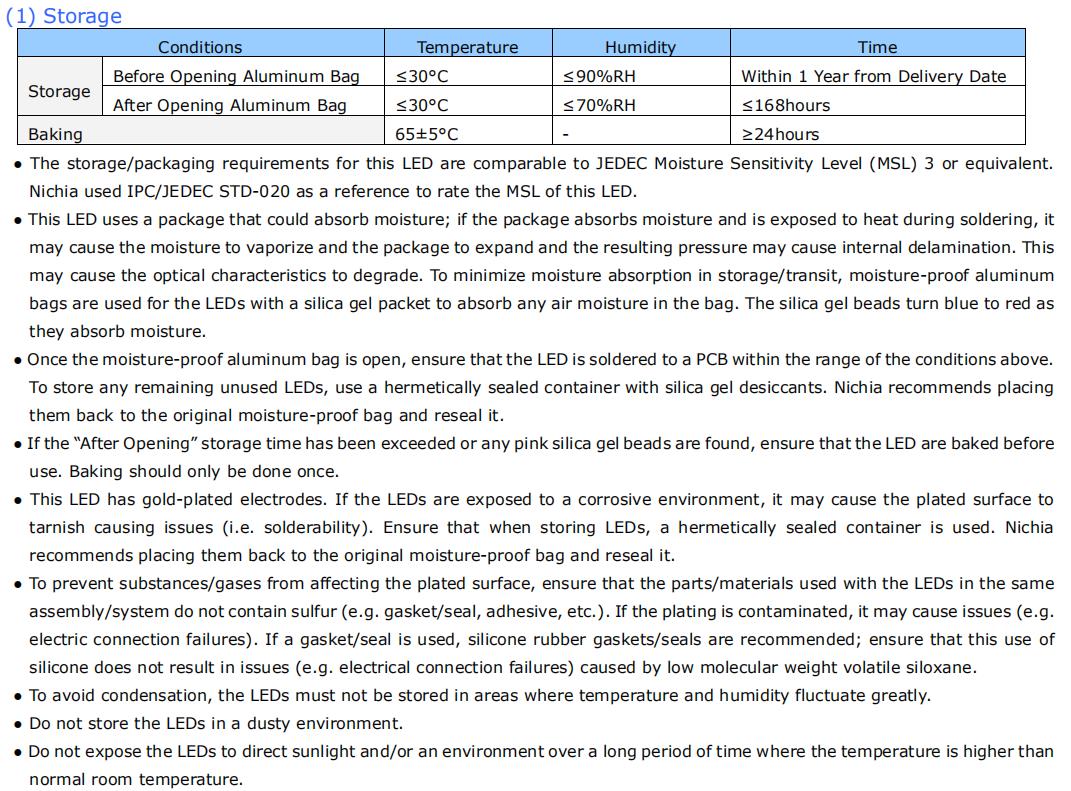

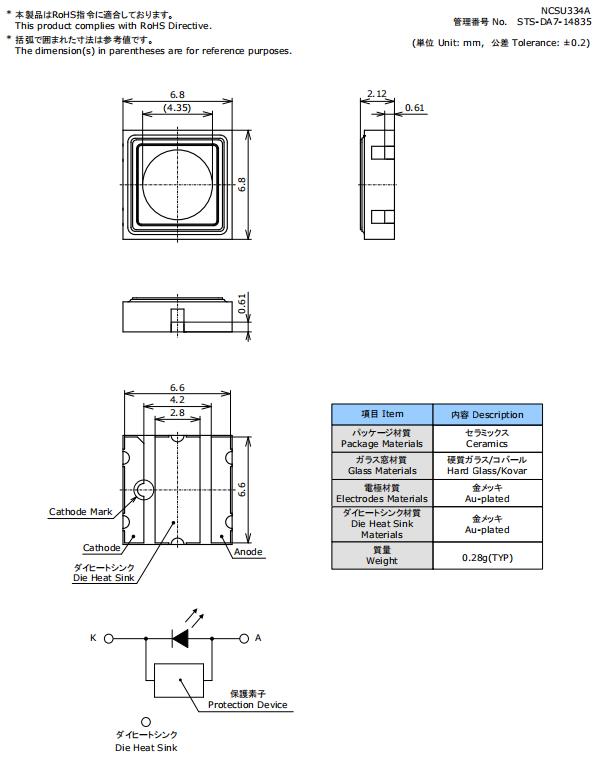

Soldering of Deep NCSU334A 280nm UV LED for Disinfection :

Recommended reflow soldering condition (lead-free solder)

1.This LED is designed to be reflow soldered to a PCB. If dip soldered or hand soldered, NICHIA will nit guarantee its reliability.

2.Reflow soldering must not be performed more than twice.

3.When the LEDs are cooled from the peak reflow temperature, ensure that the cooling is performed very gradually to avoid excessive stress on the LED (e.g. causing cracks in the solder joints). Ensure that sufficient preliminary verification is performed to ensure that there are no issues with the chosen reflow soldering conditions / process.

4.During reflow soldering, the heat and atmosphere in the reflow oven may cause the optical characteristics to degrade. In particular, reflow soldering performed with an air atmosphere may have a greater negative effect on the optical characteristics than if a nitrogen atmosphere is used; NICHIA recommends using a nitrogen reflow atmosphere.

5.Repairing should not be done after the LEDs have been soldered. It should be confirmed beforehand whether the characteristics of the LEDs will or will not damaged by repairing.

6.The Die Heat Sink should be soldered to customer PCB. If it is difficult or impossible, use high heat-dissipating adhesive.

7.When soldering, do not apply stress t the LED while the LED is hot.

8.When using a pick and place machine, choose an appropriate nozzle for this product.

9.The soldering pad pattern above is a general recommendation for LEDs to be mounted without issues; if a high degree of precision is required for the chosen application (i.e. high-density mounting), ensure that the soldering pad pattern is optimized.

10.When flux is used, it should be a halogen free flux. Ensure that the manufacturing process is not designed in a manner where the flux will come in contact with the LEDs.

11.Ensure that there are no issues with the type and amount of solder that is being used.

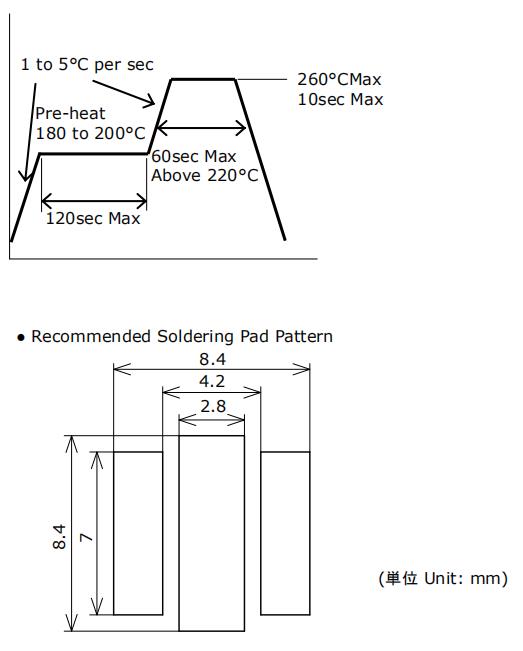

Optical characteristics of High Power NCSU334A 280NM Ultraviolet LED for Sterilization :

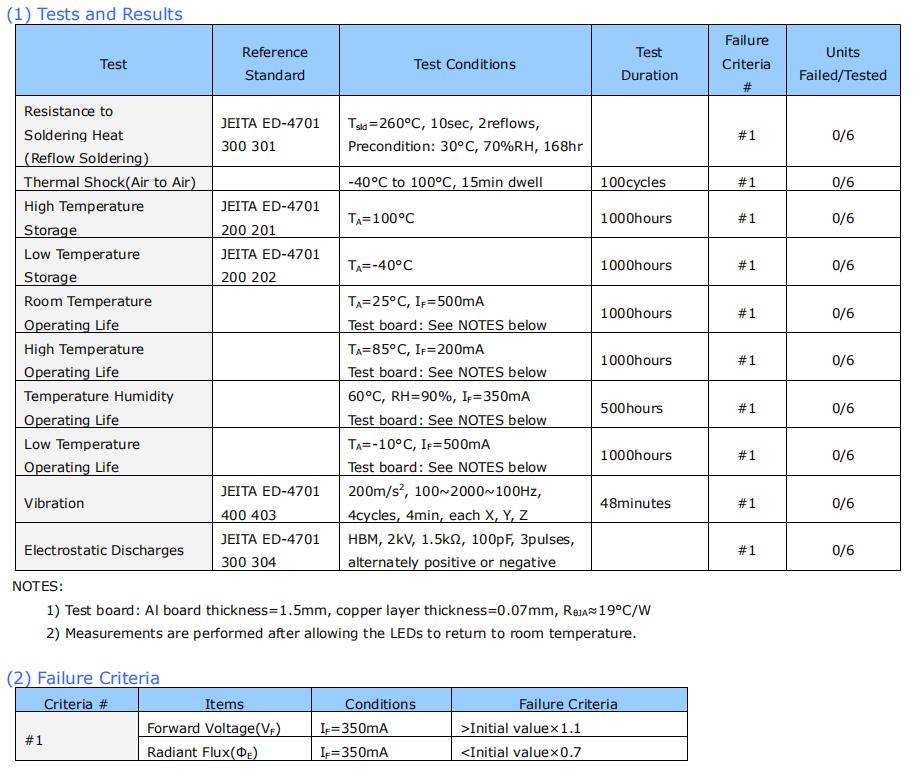

Reliability of Safety 280nm UVC UV Light for UV Flashlight :

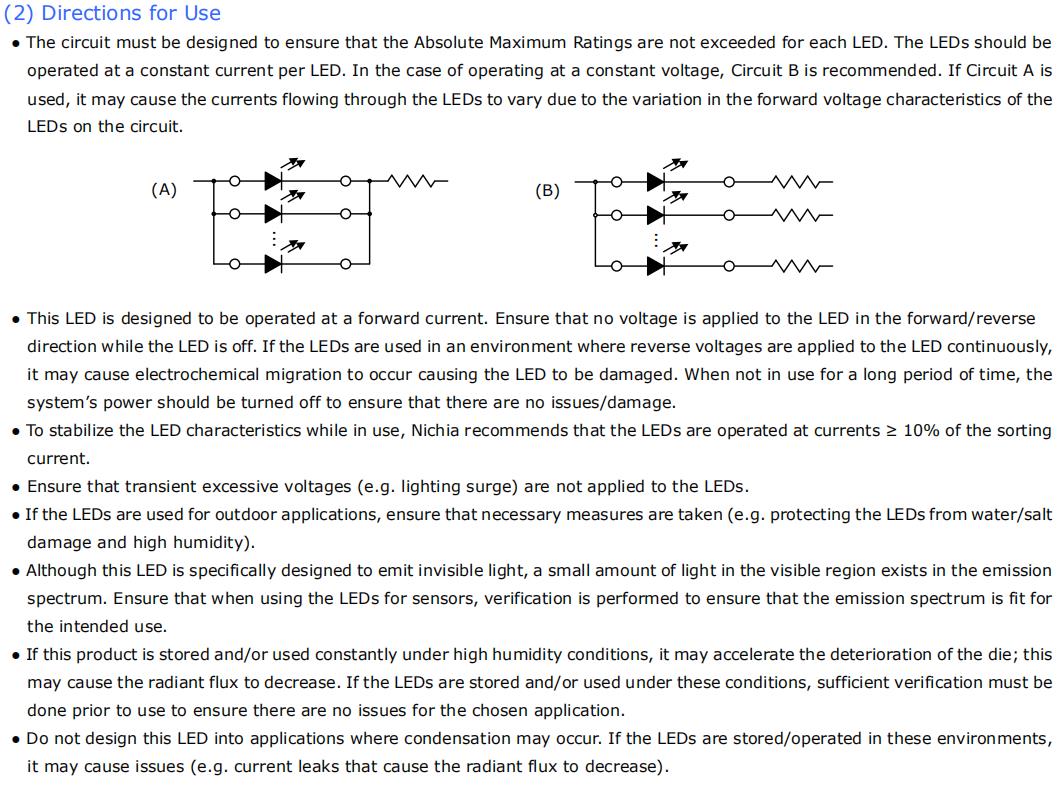

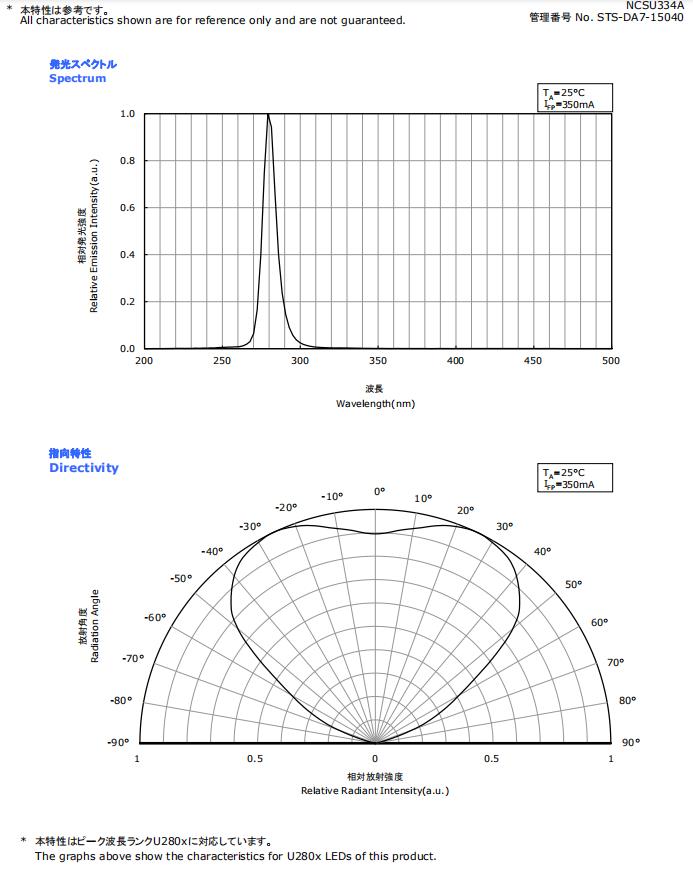

Cautions of High Efficiency NICHIA UV LED Lights 280nm UV LED for Sterilizatioin :